Vibrating screen separator

Vibrating screen separator Circular vibrating screen separator

Circular vibrating screen separator Carbon steel vibrating screen separator

Carbon steel vibrating screen separator Stainless steel vibrating screen separator

Stainless steel vibrating screen separator Straight flo vibrating screen separator

Straight flo vibrating screen separator

Safe sieving for the elimination of foreign bodies, separation of different particle sizes in the same product, and solid-liquid separation processes

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400-2000mm

Mesh size: 2-500 mesh

Capacity: 100-3300kg/hour

Layers: 1-5 layers

Power: 0.25-3 kw

Material: Carbon Steel/Stainless Steel 304/316L

Application: Dry or wet screening and separation of powder, granular, fibrous materials or slurries

Commitment:

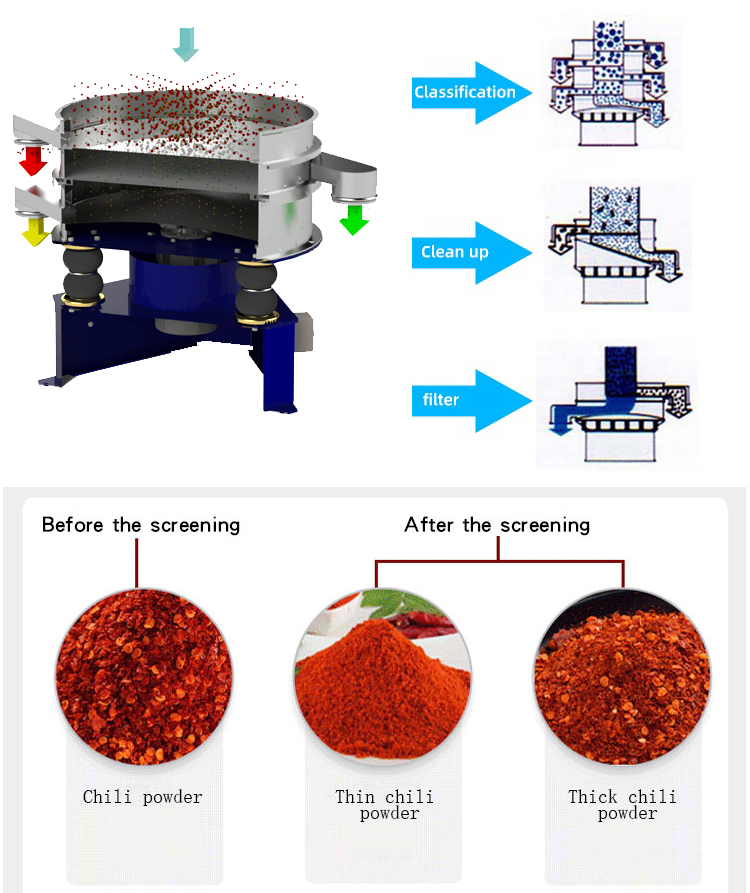

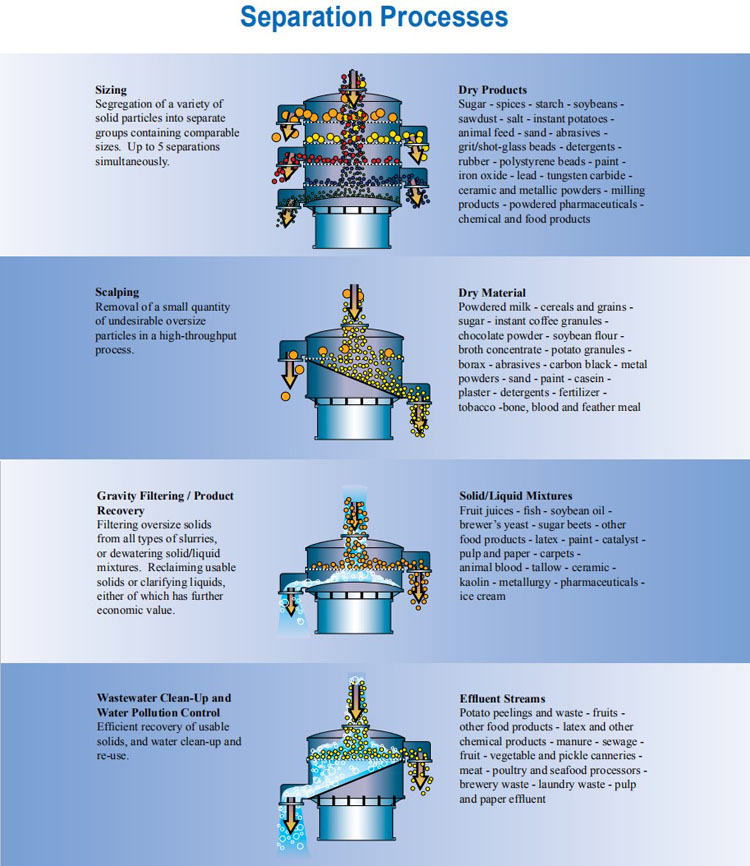

Vibrating screen separator is a versatile solution for solid and liquid sieving and filtration, by using customized layered screen and powerful 3D motion to screen products, it can be used to screen dry powder or granular products as well as wet products and liquids, it can Eliminate foreign matter in the product with continuous filtration for up to 5 stages of product separation in just 1 operation.

Vibrating screen separators are available in various sizes (from 400mm to 2000mm) to meet the screening needs of different industries, allowing a production volume of 100 to 3300kg/h, and are widely used in food and beverages, pharmaceuticals, paper and pulp, metal powder, industries such as powder coatings, and can be fully customized to your application.

Vibrating screen separator is the most common form of sieving, which can remove impurities in products through inspection screening to ensure product quality while ensuring high throughput, suitable for sieving and filtration of particles, powders, liquids, including food, feed, plastics Granules, ceramic powders, metal powders, etc.

1. Removal of agglomeration, contaminants in products: usually a single screen, usually fine products that pass through the screen are retained as good products, and can also be used to remove broken or undersized products.

2. Product grading/separation: Vibrating screen separator is equipped with 1 to 5 meshes with different aperture sizes, which are stacked on each other, the largest particles/parts remain on the screen surface, and the finest particles are discharged from the discharge port at the bottom, which can be Separation of powders and granules into 2-5 different sizes, dry and wet screen opening sizes can be 0.25-20 mm.

3. Solid-liquid separation: It is used to screen out solid organic and/or inorganic substances from liquids, and the mesh size is 25 microns to 20 mm.

Vibratory Separation Equipment

It is mainly used when the viscosity of the liquid material is not large and it is easy to filter. If the juice is filtered, in order to prevent the slurry material from splashing during the screening process, it is often necessary to design the upper frame to be 10cm higher. The motor adopts a four-stage motor. The rotational speed is 1440r/min.

Filter Sieve

It is mainly used for the filtration of small household liquids. Usually, there is no upper discharge port. The upper layer of impurities needs to be removed from the screen frame after a period of time, and the impurities are disposed of by themselves. For example, it is used in the filtration of soy milk with smaller yield.

High Frequency Vibrating Screen

This screen machine is used to filter viscous slurry. The vibration source of the equipment is a high-frequency vibration motor, that is, the speed of the motor can be as high as 3000r/min. This high-frequency rotation speed can destroy the tension of the slurry and force the slurry to achieve the purpose of separation. , such as ceramic mud, brown sugar filter, etc.

Vibrating screen separator uses YZUL vertical vibration motor as the power source. When the machine starts, after the crushed materials with different particle sizes and mixed thicknesses enter the screen surface, due to the vibration of the screen, the material layer is dispersed, and the small particles take the opportunity to pass through the gap to transfer. On the screen surface of the lower layer, due to the small gap between small particles, large particles cannot pass through and will stay on the screen surface, so the original disordered particle group is separated, that is, it is layered according to particle size, forming small particles. In the bottom, the coarse particles are arranged regularly, and the fine particles that reach the screen surface, those smaller than the sieve hole pass through the screen, and finally realize the separation process of coarse and fine particles.

Wet and dry sieving

Can be used for dry powder or granular materials as well as wet screening products and liquids, dry and wet screen opening size can be 0.25-20.0 mm.

Higher capacity

The horizontal, inclined and vertical 3D vibration movement allows the material to pass through the screen more quickly, allowing the production capacity of 100-3300kg/h per hour.

1-5 stage separation

Vibrating screen separator is equipped with 1-5 different pore size screens, stacked on top of each other, enabling powders and granules to separate products from 2-5 different sizes/fractions, with the largest particles/fraction from the top sieve plate The separator is removed, and the finest particles are removed from the lowest screen cloth at the bottom.

Small Footprint

This Vibrating screen separatorr uses a pedestal base, which is compact and does not require excessive headroom in the installation and process, can be flexibly installed in various production lines. The vibrating screener is fully portable allowing one unit to be used in various locations across your plant.

Improved hygiene and cleanability

Open frame design allows for easy disassembly and cleaning.

Closed system

Closed system eliminates airborne dust problems and manual interaction is pollution-free.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

The customization types of vibrating screen separator depend on the specific application and the requirements of the customer. Some of the common customization types include:

Edged type: The specially designed edged type is a model with large feeding capacity, preventing material splashing, and easy to observe the screen.

Silo type: By adjusting the butterfly valve in the silo to control the flow of materials entering the vibrating screen, and then the vibrating screen performs screening operations. This product is characterized by intermittent feeding, which saves labor without continuous feeding by workers. The flow rate controlled by the butterfly valve can be improved. Screening accuracy.

Mobile type: universal wheels are installed at the bottom, which can rotate and move 360 degrees. It is mainly used in the environment where the screening site is not fixed, which is convenient for users to move and meet the work needs of different locations.

Vibrating screen separators are available in a variety of options to suit different applications and material requirements. Some common options include:

1. Screens: Different types of screens can be used including wire mesh, perforated plate or polyurethane screens. Screening media selection is based on the specific application and the particle size distribution of the material being screened.

2. Sieve plate design: Can be designed as single or multiple sieve plates to suit specific applications. The number of sieve trays can be adjusted according to the desired particle size distribution and production rate.

3. Vibration intensity and frequency: The vibration intensity and frequency can be adjusted to optimize the screening process and achieve ideal particle separation and classification.

4. Flow Control: Feed and discharge chute can be designed to control the flow of material into and out of the screen deck to ensure efficient and consistent screening.

5. Dust cover and seal: Dust cover and seal can be installed to prevent dust and other pollutants from escaping during the screening process.

6. Screen cleaning device: brushes, bouncing balls, ultrasonic deblinding systems and other screen cleaning devices can be installed to keep the screen medium clean and free from blockage.

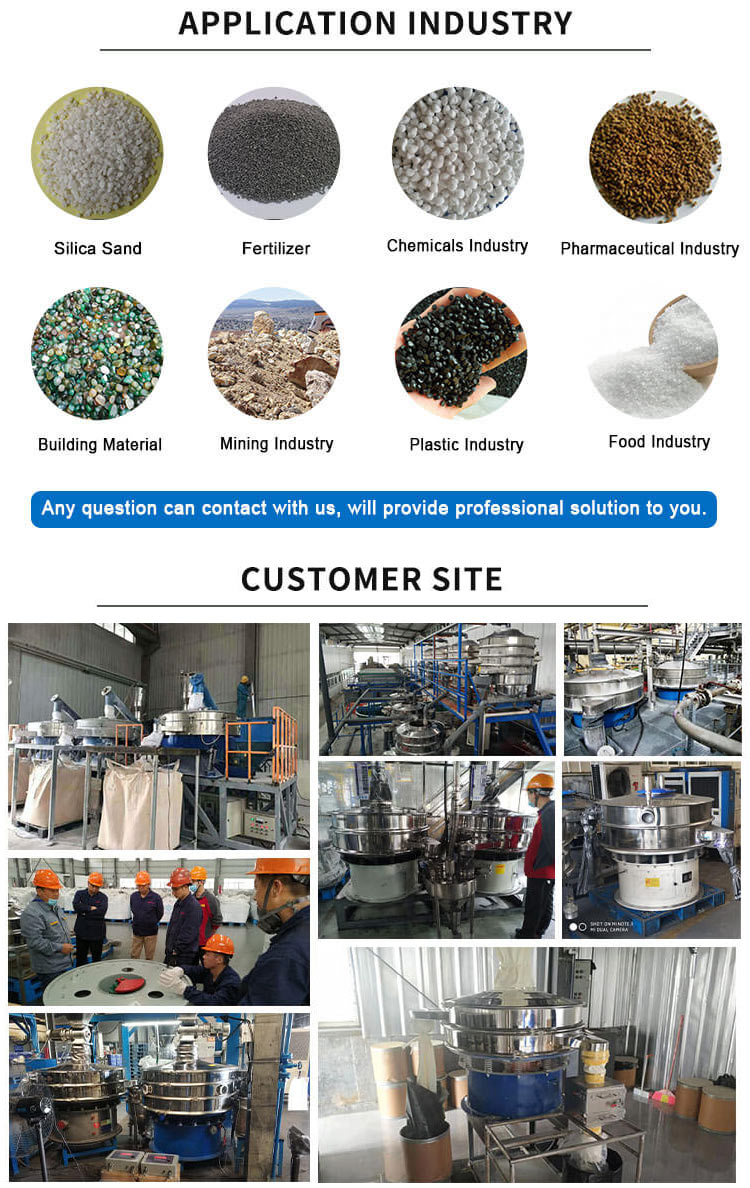

Vibrating screen separator is widely used in various industries to separate and classify particles according to their size and shape. Common industries include:

1. Mining: Separation and classification of minerals and ores according to their particle size distribution.

2. Food and beverage: It is often used in the food and beverage industry to separate and grade foods such as grains, flour, sugar and spices.

3. Pharmaceutical: It is often used in the pharmaceutical industry to separate and classify medicines such as pills and tablets.

4. Chemical industry: It is often used in the chemical industry to separate and classify chemical fertilizers, pesticides and other chemicals.

5. Recycling: It is often used in the recycling industry to separate and classify recycled materials such as plastics, metals, and paper.

6. Construction: It is often used in the construction industry to separate and classify construction materials such as sand, gravel, and concrete.

7. Plastics: Commonly used in the plastics industry to separate and classify plastic particles and flakes according to their size and shape.

| Material | Process Way | Mesh size (mesh) |

Capacity (kg/hour) |

| Milk powder | dry | 16.2 | 2000 |

| Granulated sugar | 4.2 | 5000 | |

| Pigment powder | 20 | 4000 | |

| Iron powder | 60 80 120 | 2500 | |

| Copper powderr | 80 | 2000 | |

| Stone copper powder | 40 65 200 | 2000 | Aluminum silver powder | 60 | 1500 |

| Starch | 80 | 1200 | Metal powder | 100 1500 200 | 1200 |

| Activated carbon | 40 60 | 1000 | Coating | wet | 100 | 7500 |

| Food processing wastewater | 20 | 3500 | Papermaking clay mud | 1 | 3500 |

Our wide range of vibrating screen separators separate bulk solid materials from solids, powders and slurries. The following applications highlight common materials we create for processing solutions using our vibrating screen separator equipment:

1. Screen waste oil and grease

Waste oils and greases are screened to remove solids by vibrating the material on one or more screens to separate bulk solids from solids and slurries.

2. Screening plastic particles

The plastic particles are separated from the fines by a round wire mesh screen. Undersized plastic fines (bottom) are sieved from the right sized granules to ensure product consistency.

3. Screening and separation of grains

It separates seeds, stems, chaff, straw and other materials from grain products. These screeners range in diameter from 400mm to 2000mm and capacities from a few pounds/kg to over 30 metric tons per hour. Our units can also separate particles from one to five sizes from 2 inches (50 mm) to 400 mesh (37 microns).

4. Walnut powder separation and dust removal

It can easily dedust crushed walnuts and these sieves operate in batches or continuously at speeds ranging from 100kg to 5000kg per hour.

Dahan vibrating screen separator manufacturer is located in Henan Province, China. It has many years of experience in the production and sales of vibrating screen separator equipment, and provides customized services for many brands. It is a company integrating production and trade.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.