The cement vibrating screen is a vibrating screen for screening the cement production line. This article will introduce the use of the cement vibrating screen for you.

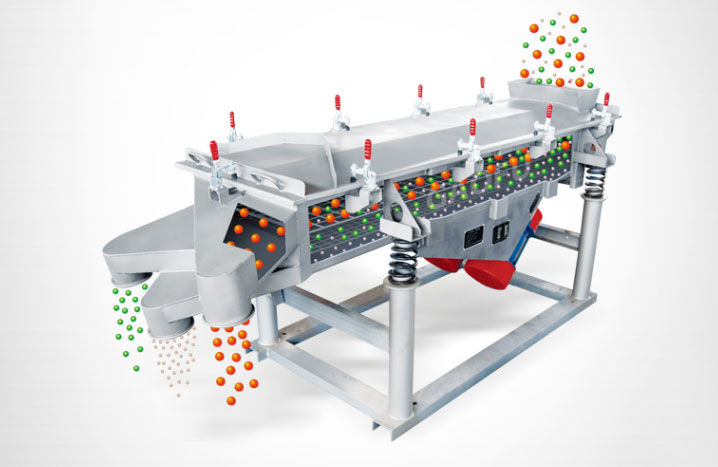

1. Because in cement production, the clinker is crushed by a fine crusher to below 5mm and then crushed by a mill, which can greatly increase the output of the cement mill by about 30%, and save about 18% of electricity, so this new process is adopted It is used by many cement manufacturers. In order to ensure that the particle size of the clinker entering the mill is less than 5mm, the clinker particles above 5mm need to be selected and crushed again. Therefore, a clinker vibrating screen must be installed between the fine crusher and the cement mill. This screen machine can also be used for raw materials. Classification and screening of cement vibrating screen as the pre-stage supporting equipment of various cement packaging machines is also an indispensable equipment in the cement production process. Since the cement industry has high requirements on the particle size of the finished product, it must be passed through before the product is packaged. In the final inspection process, the cement vibrating screen is used to screen out agglomerates and foreign matter in powdery materials such as cement to ensure the quality of the product.

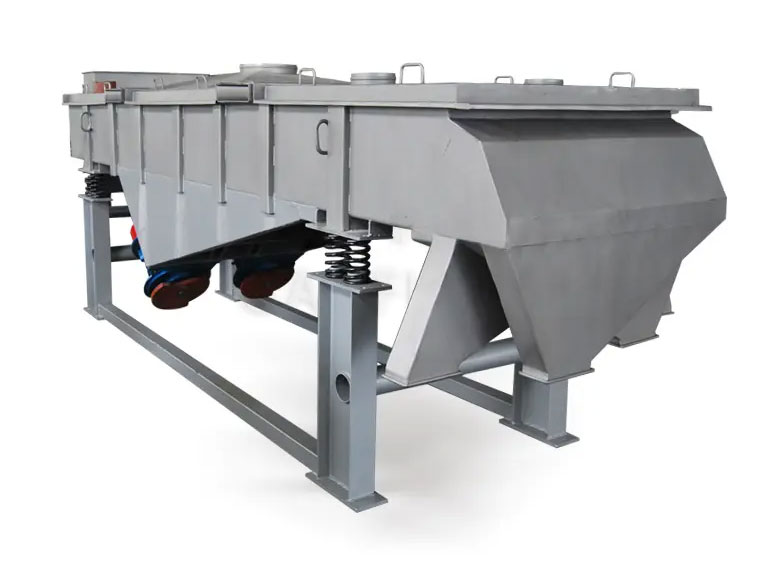

2. It is mainly used as the pre-stage supporting equipment of various cement packaging machines. It is used to screen out agglomerates and foreign objects in powdery materials such as cement before packaging cement products. It can also be used for sorting of granular materials. From a structural point of view, the tensioned screen is used to make the fatigue stress of the screen steel wire small, and the screen surface does not appear concave. Due to the large amount of dust in the cement production process, this type of vibrating screen is usually fully enclosed to reduce the pollution of the working environment.

Because cement production has relatively strict requirements on the particle size of materials, the degree of crushing of materials directly affects the reduction of production costs. In cement production, the clinker is first crushed by the fine crusher to less than 5 mm and then crushed in the mill, which can achieve considerable economic benefits of increasing the output of the cement mill by about 30% and saving electricity by about 18%. This new process has been adopted by many manufacturers. In order to ensure the particle size of the clinker fed into the mill and select the clinker particles larger than 5 mm for re-crushing, a clinker screen must be installed between the fine crusher and the cement mill.

According to the requirements of this process, the cement vibrating screen adopts two layers of coarse and fine screens, which have the characteristics of high screening efficiency, fast slag discharge, long life, low energy consumption, small size, light weight, etc., and because of its reliable use , Easy to install and maintain, it is very convenient to clean the sundries on the screen surface and replace the screen and damping spring, so it is welcomed by users. This vibrating screen can be used not only for clinker screening but also for raw meal and other materials. point.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.