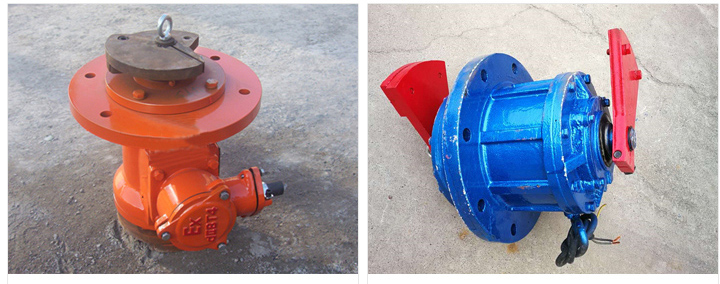

The vibration motor can be said to be the most important power source of the vibration motor, and the speed and amplitude of the vibration motor are closely related to the vibration amplitude of the vibrating screen.

The manufacturer of the vibrating motor will choose the type of vibrating screen, material conditions, and screening requirements. At the same time, the manufacturer will complete the debugging of the angle of the eccentric block of the vibrating motor before the machine leaves the factory.

Then, if the screening effect is not ideal or the condition of the screened materials changes in the actual use process, you can adjust the eccentric block of the vibration motor by yourself to change the vibration condition and screening efficiency of the vibrating screen.

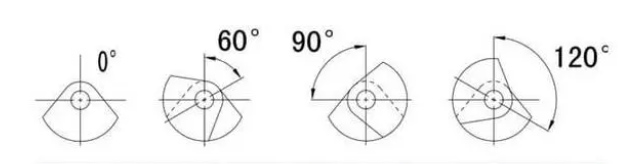

The general principle of adjusting the eccentric block is: the smaller the included angle of the eccentric block, the larger the exciting force and the larger the amplitude; the larger the included angle of the eccentric block, the smaller the exciting force and the smaller the amplitude.

However, it is not possible to blindly pursue large amplitude and unrestrictedly reduce the angle of the eccentric block of the vibration motor. Excessive amplitude will cause the material to splash or disperse too fast, which will greatly reduce the screening accuracy; excessively increasing the angle of the eccentric block will lead to too small amplitude. The material cannot be effectively dispersed, and the material accumulation is formed in the center of the screen surface, which affects the screening output.

Therefore, the angle adjustment of the eccentric block can generally be considered from three aspects.

First, for finer materials, the mesh is relatively large, and the angle of the eccentric block can be adjusted to about 5 degrees to 15 degrees, so that the materials can quickly spread out on the screen surface to the edge of the screen, and pursue greater output.

Second, when the mesh size is 40 mesh to 80 mesh, it is necessary to appropriately extend the running time of the material on the screen to make the screening of the material more accurate, 30 degrees to 45 degrees.

Third, for materials with a mesh number of 80 or more, the angle of the eccentric block should be adjusted to between 60 degrees and 85 degrees, so as to prolong the screening time and running track of the materials on the screen as much as possible to achieve the best screening. Effect.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.