Cement vibrating screens are widely used to screen out cement, lime and similar powdery materials to ensure the safe operation of conveying equipment and packaging. The application of cement vibrating screen in cement plant will be introduced in detail below.

The cement vibrating screen is specially used for cement screening. It is generally installed above the packaging warehouse. The ambient temperature does not exceed 40°C. It is suitable for screening cement and other powder materials within 400 meshes. The screening output can reach 200 tons per hour, and can be customized according to the user's output. Special models are required to be customized, and the shortcomings of traditional vibrating screens such as blocked sieve, sticky screen, and difficulty in replacing the screen have been overcome.

Cement shakers are an essential part of the cement production process, helping to ensure the quality and consistency of the final product. They are versatile machines that can be used in a variety of applications from raw material preparation to recycling, mainly including:

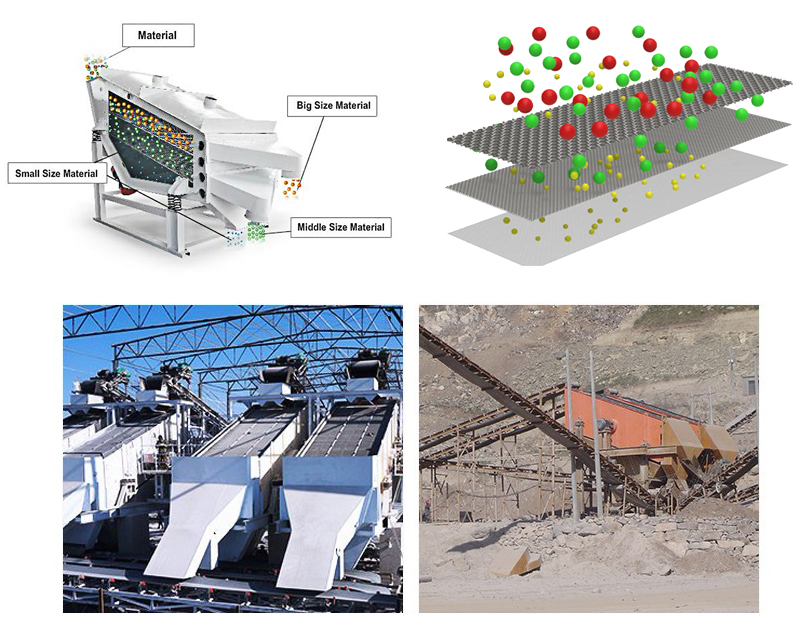

1. Raw material preparation: During the cement manufacturing process, limestone, clay, sand and other raw materials are crushed and ground into fine powder, and cement vibrating screens are used to separate raw materials of different sizes and remove any impurities.

2. Cement Grinding: After the clinker is cooled, it is ground with gypsum to make cement, which is used to separate the ground cement particles into different sizes and remove any oversized particles.

3. Cement storage and packaging: After the cement is produced, it is stored in silos before it is packed into bags or shipped in bulk. Cement vibrating screens can be used to ensure that the cement is evenly distributed in the silo and to remove any Lumps or impurities.

4. Recycling: Cement plants produce a large amount of waste materials, such as cement kiln dust, fly ash, etc., and cement vibrating screens are used to separate these materials into different sizes and remove any impurities before recycling.

Conditions of Use

1. The vibration acceleration does not exceed 20G (g: 9.8m/s gravity acceleration).

2. The ambient temperature does not exceed 40°C (if it exceeds 40°C, the power should be reduced).

3. The altitude does not exceed 1,000 meters. If the altitude exceeds 1,000 meters but does not exceed 4,000 meters, the temperature rise limit should be reduced by 0.5°C for every 100 meters above sea level.

4. Power supply: three-phase 380V, frequency 50Hz.

5. Working mode: SI (continuous)

6. The temperature rise of the stator group (resistance method) does not exceed 80K.

7. The bearing temperature (thermometer method) should not exceed 95°C.

8. The operating current of the main engine should not exceed the data on the nameplate of the motor, otherwise reduce the excitation force.

9. The operating environment should be free of conductive dust, flammable, explosive and corrosive gases.

The cement vibrating screen is mainly the pre-stage supporting equipment of various cement packaging machines. It is used to screen agglomerates and foreign objects in powder materials such as cement before packaging cement products, and can also be used for sorting granular materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.