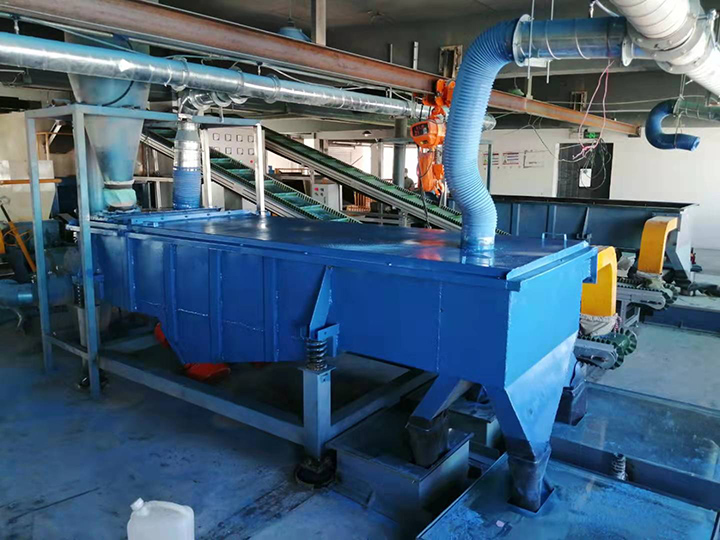

Linear vibration machine

Linear vibration machine Carbon steel linear vibration machine

Carbon steel linear vibration machine Stainless steel linear vibration machine

Stainless steel linear vibration machine Multilayer linear vibration machine

Multilayer linear vibration machine Linear vibration sieve machine

Linear vibration sieve machine

Impurity removal, filtration, material classification, solid-liquid separation, screening

![]()

![]()

![]()

Price:$860.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Function:filter\separate\sort\sieve

Material:Carbon Steel, Stainless Steel 304/316

Particle Size:0.074-10mm

Mesh Size:2-400 mesh Capacity:0.12-20t/h

Layers: 1-6 layers

Application: screening of coarse, medium and fine materials, which can be classified and impurity removal

Commitment:

Linear vibration machine was invented to handle high feed flow, also called linear vibration sieve machine, it can be used for screening, grading, deblocking, dewatering any bulk solids or slurries, the sieving accuracy reaches 200 mesh (0.074mm), 6 Layer design, can screen 2-7 different particle size materials at the same time.

Linear vibration machine is driven by dual vibration motors. When the two vibrating motors rotate synchronously and in opposite directions, the exciting force generated by the eccentric blocks cancels each other out in the direction parallel to the motor axis, and stacks into a resultant force in the direction perpendicular to the motor axis, so the trajectory of the screen machine It is a straight line, and the two motor shafts have an inclination angle in the vertical direction relative to the screen surface. Under the combined force of the exciting force and the material's self-gravity, the material is thrown up and jumped or moved forward on the screen surface in a straight line, so as to achieve the screening of the material. And the purpose of grading.

Sieving plastic particles

Sieving sand

multi-layer control

The multi-layer screen produces several specifications of the above and below the sieve, which are discharged from their respective outlets, and a maximum of 7 different specifications can be obtained at one feeding.

large output

Due to its large screening area, the material stays on the screen for a long time, the screening efficiency is as high as 96%, and the processing capacity can reach 20 tons/hour.

continuous movement

Equipped with a 2.2kw vibration motor, it can work continuously for dozens of hours, and the impurities and coarse materials are automatically discharged and run continuously, which is more suitable for the installation and use of the assembly line.

No dust pollution

Fully enclosed structure, dust does not spill, the upper cover of the linear vibration machine equipment is designed with a dust removal device, which can be easily connected to the on-site dust removal equipment and improve the working environment.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

The structure of linear vibration machine includes: screen mesh, screen box, dust cover, feeding port, vibration motor and discharging port, etc.

Screen: It is mainly used for material screening. There are many kinds of apertures of the screen, which can be installed according to different needs.

Screen box: The screen box is mainly used to hold the materials that need to be screened. The materials in the screen box do parabolic motion on the screen under the action of the vibration motor to achieve the purpose of screening.

Dust cover: Many users screen some dry dust-containing materials. In order to ensure that the dust does not escape, the manufacturer has developed a dust cover.

Inlet/Outlet: This is mainly used for the material entering the screen box as the inlet, and the position where the material is screened and discharged is the outlet.

Vibration motor: The use of vibration motor is relatively extensive, and the main function of the vibration motor of linear vibration machine is to vibrate, to drive the movement of materials on the screen, so as to achieve the purpose of screening.

Linear vibration machine cleaning device (bouncing balls) are evenly distributed on the pallet, generally 5-8 within ten centimeters. The bouncing balls also jump and hit the screen while the screen machine is vibrating and sieving. The purpose of clearing the net.

| Materials | Specific gravity | Mesh | Capacity kg/h |

Model | |

| Name | Image | ||||

| Millet |  |

0.15 | 250 mesh | 600 | DZSF-515-2s |

| Quartz sand |  |

1.6 | 70 mesh | 30000 | DZSF-1540-3s |

| Raisin |  |

0.83 | 60 mesh | 6000 | DZSF-520-1s |

| Sunflower seeds |  |

0.04 | 80 mesh | 7100 | DZSF-525-1s |

| Plastic particles |  |

0.95 | 3 mm | 500 | DZSF-515-2s |

| Flour |  |

0.6 | 24 mesh | 1500 | DZSF-515-3S |

| Iron ore powder |  |

2.3 | 150 mesh | 10000 | DZSF-1020-3s |

| Slag |  |

4 | 5 mm | 10000 | DZSF-1020-1s |

| Sawdust |  |

0.2 | 80 mesh | 18000 | DZSF-1030-3S |

| Emery |  |

4 | 60 mesh | 300 | DZSF-515-1Ss |

| Wood flour |  |

0.4 | 120 mesh | 2000 | DZSF-1036-4s |

| Activated carbon |  |

0.8 | 36 mesh | 500 | DZSF-515-1s |

Food industry: sesame, peanuts, soybeans, wheat bran, corn, spices, salt, starch, etc.

Pharmaceutical industry: Chinese medicine powder, pellets, pellets, etc.

Chemical industry: urea, fertilizer, coke, activated carbon, etc.

Metallurgical industry: refractory materials, kaolin, lime, alumina, quartz sand, lead powder, aluminum powder, etc.

The linear vibration machine produced by Dahan Machinery has complete technical parameters. It is mainly used for impurity removal and classification of dry powder and granular materials. It is widely used in food, medicine, chemical industry, building materials, metallurgy, plastics, abrasives and other industries. If you have special requirements (such as material, number of layers, installation size, etc.), our technical engineers will design according to your screening needs to ensure that they can meet your requirements. Online and offline purchases are adopted, there are no middlemen and redundant links, and the price is more transparent. In addition, we can also provide free trial machine, door-to-door delivery, delivery training, spare parts supply, and complete follow-up tracking. Service, arrive at the scene within 72 hours to solve user problems, and fully protect the rights and interests of users.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.