Used in cement plants to remove unwanted particles during the production process and ensure the quality of the final product.

![]()

![]()

Price:$580.00-$4,500.00/Set

Consult now and enjoy a 10% discount

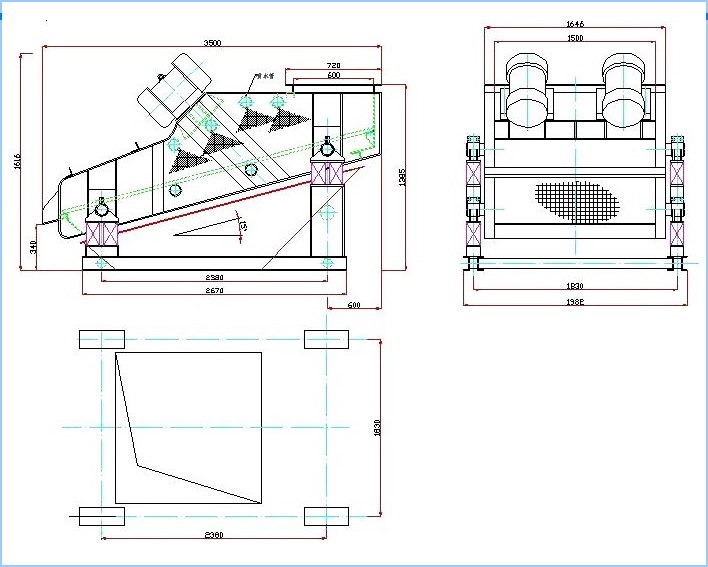

Mesh: Size:10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

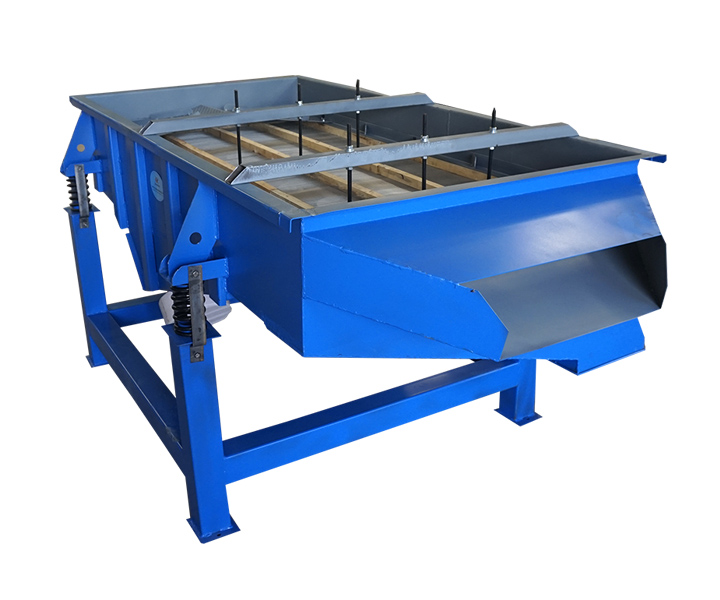

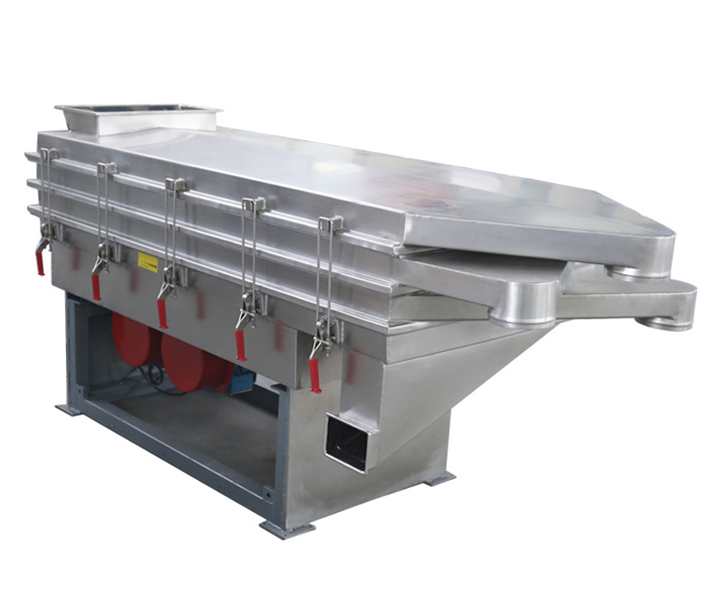

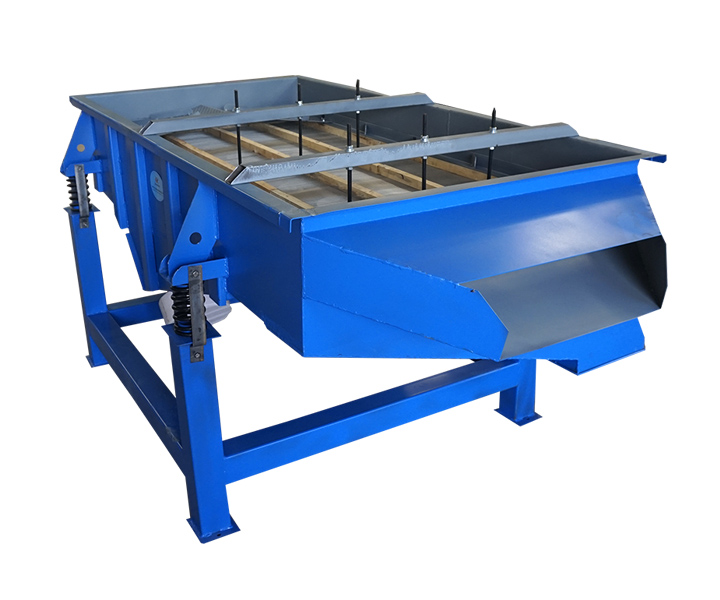

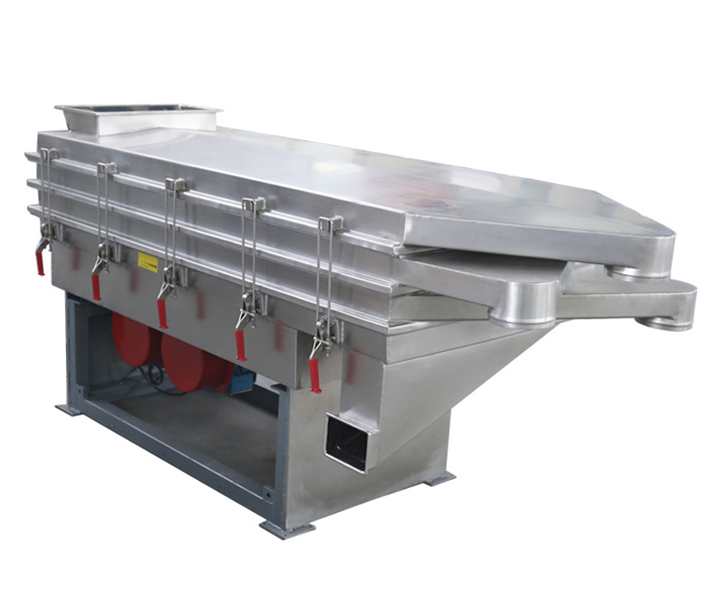

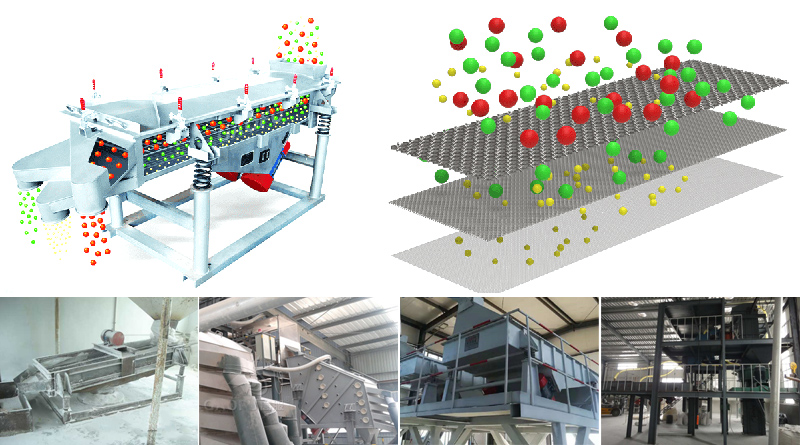

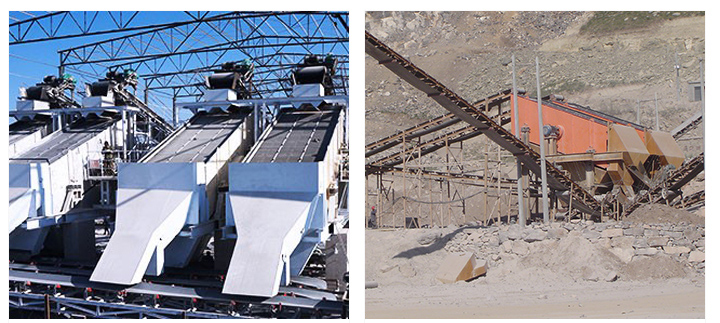

Cement vibrating screen is a type of equipment used in the cement industry to separate and classify various materials. It is commonly used in cement plants during the production process to remove unwanted particles and ensure the quality of the final product.

Cement vibrating screens are usually installed at specific locations in cement production lines for preliminary screening and classification of cement particles. It removes impurities and oversized or undersized particles from the cement, improving the quality and consistency of the cement. The vibrating screen uses high-quality high-manganese steel braided mesh, which is durable and easy to replace and maintain. The screen mesh is generally 4*4mm or 5*5mm; it can also be customized according to customer requirements.

Cement vibrating screens have many applications in the cement industry, including the following aspects:

1. Raw material screening: The first step in cement production is to screen the raw materials to remove impurities and unwanted particles. Cement vibrating screens can be used for preliminary screening and classification of raw materials to ensure that only particles that meet the requirements enter the subsequent production process.

2. Clinker screening: Cement clinker is a calcined raw material and plays an important role in cement production. Vibrating screens can be used to screen clinker to control particle size and distribution to ensure the quality and uniformity of clinker.

3. Kiln dust treatment: Kiln dust generated in cement production is a kind of solid waste that needs to be treated and recycled. Cement vibrating screens can be used to screen and classify kiln dust to separate recyclable particles and other wastes and realize resource utilization of kiln dust.

4. Grinding system: The grinding system in cement production needs to grind clinker into cement powder with appropriate fineness. Vibrating screens can be used to screen ground cement to remove coarse or fine particles, adjust the particle size distribution of cement, and improve the quality of cement.

5. Finished product screening: Finally, cement vibrating screens can also be used to screen and classify finished cement. Through the screening function of the vibrating screen, the finished cement can be classified according to different particle sizes to meet different application needs.

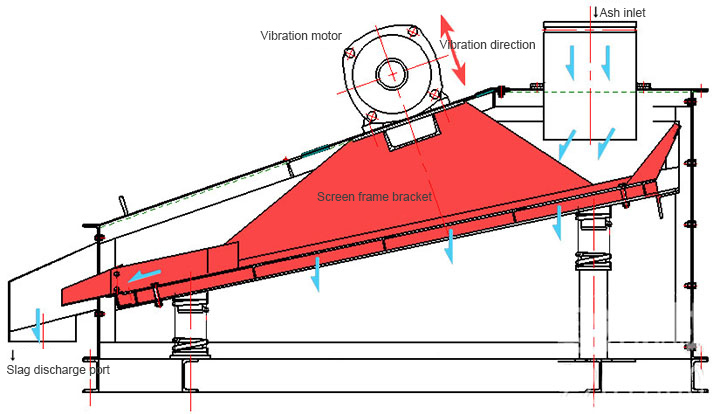

The material falls into the screen from the upper feeding port of the cement vibrating screen, and the screen frame is fixed with the vibrating motor, so the screen moves in an approximately circular trajectory with the vibration of the vibrating motor. The material is continuously thrown up on the screen and moves forward and downward. The powder and particles smaller than the mesh size in the material will fall through the screen. The sundries larger than the mesh size are discharged from the screen surface through the slag outlet, thus completing the screening work. The damping spring is to reduce the vibration force of the machine on the ground. The protective net is to prevent tools or other objects from falling into the silo during installation and maintenance.

Efficient particle separation

Vibrating screens effectively separate particles of different sizes in cement mixtures. This helps ensure that only the desired particle size range is included in the final cement product, thereby improving its quality and consistency.

Improve production capacity

The use of cement vibrating screens can increase the production capacity of cement plants by efficiently processing large amounts of material in less time. This can increase production and increase overall efficiency.

Flexible installation methods

It can be seat-mounted, with the vibrating screen directly installed on the middle bin of the packaging machine, or it can be hoisted, with the vibrating screen hung under the upper floor of the packaging machine's middle bin.

Reduce downtime

Vibrating screens are generally easy to maintain and clean. Regular maintenance and cleaning help prevent blockages and ensure smooth operation, reducing downtime and increasing overall cement plant productivity.

Versatility

Cement vibrating screens can be designed to accommodate various types of cement materials, including dry powder, wet slurry, and even sticky materials. This versatility enables its application in different stages of the cement production process, from raw material screening to final product classification.

Customizable designs

Cement vibrating screens can be customized to meet specific requirements such as screen size, screen surface material and vibration characteristics. This allows for optimal performance and efficiency tailored to the cement production process.

| Model | Screen area (m²) | Screen inclination (°) | Mesh size(mm) | Feed size (mm) | Capacity (t/h) | Double amplitude(mm) | Power(kw) | Vibration times (t/min) |

| SZS615 | 0.9 | 0~10 | 1-20 | <50 | <30 | 6-8 | 0.55×2 | 960 |

| SZS815 | 1.2 | 0~10 | 1-20 | <50 | <50 | 6-8 | 0.75×2 | 960 |

| SZS1020 | 2 | 0~10 | 1-50 | <100 | <100 | 6-8 | 0.75×2 | 960 |

| SZS1224 | 2.88 | 0~15 | 1-50 | <100 | <120 | 6-8 | 1.5×2 | 960 |

| SZS1530 | 4.5 | 0~15 | 1-50 | <100 | <200 | 6-8 | 1.5×2 | 960 |

Cement vibrating screen is mainly composed of machine body, sieve bed, feeding device placed on the upper part of sieve bed, vibrating motor, sieve bed, sieve plate and other parts. The sieve plate is provided with holes, and the sieve bed is double-layered and inclined, including the connection between the lower sieve bed and the machine body through elastic supports, and the fixed connection between the upper sieve bed and the lower sieve bed, and the sieve bed is composed of supports.

Cement vibrating screens are mainly used for screening in the cement production process. Common application scenarios include the following aspects:

1. Cement production line: Cement vibrating screens are usually installed at specific locations in the cement production line to conduct preliminary screening and classification of cement particles. It removes impurities and oversized or undersized particles from the cement, improving the quality and consistency of the cement.

2. Concrete mixing station: In the concrete production process, cement vibrating screens are often used to screen cement particles in concrete ingredients. By controlling the screen aperture, you can ensure that the cement particles in the concrete batches meet the requirements and improve the quality and strength of the concrete.

3. Construction site: On the construction site, the cement vibrating screen can be used for on-site cement screening work. For example, during concrete construction, a cement vibrating screen can be used to screen bagged cement to remove granular impurities and ensure the quality of the cement.

1. The vibration acceleration does not exceed 20G (g: 9.8m/s gravity acceleration).

2. The ambient temperature does not exceed 40°C (if it exceeds 40°C, the power should be reduced).

3. The altitude does not exceed 1,000 meters. If the altitude exceeds 1,000 meters but does not exceed 4,000 meters, the temperature rise limit should be reduced by 0.5°C for every 100 meters above sea level.

4. Power supply: three-phase 380V, frequency 50Hz.

5. Working mode: SI (continuous)

6. The temperature rise of the stator group (resistance method) does not exceed 80K.

7. The bearing temperature (thermometer method) should not exceed 95°C.

8. The operating current of the main engine should not exceed the data on the nameplate of the motor, otherwise reduce the excitation force.

9. The operating environment should be free of conductive dust, flammable, explosive and corrosive gases.

The following is an example of a cement vibrating screen customer case sheet:

| Application occasions | Purpose of usage | Mesh size | Capacity |

| Cement production line | Preliminarily screen cement particles to remove impurities and adjust particle size distribution | 3 mm | 50 tons/hour |

| concrete mixing station | Screening cement particles in concrete batches to improve quality | 5 mm | 30 tons/hour |

| construction site | Screen bagged cement to remove granular impurities | 2 mm | 10 tons/hour |

| laboratory | Conduct sieving experiments and research on cement samples | 1 mm | 2 tons/hour |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.