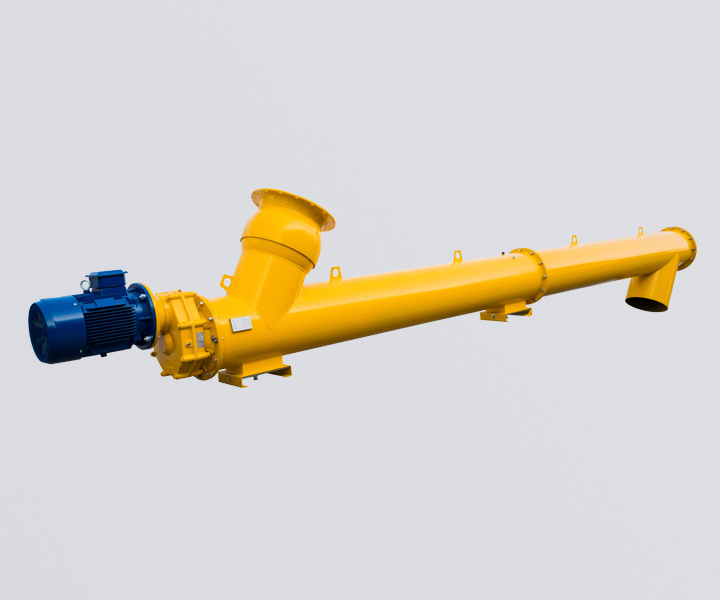

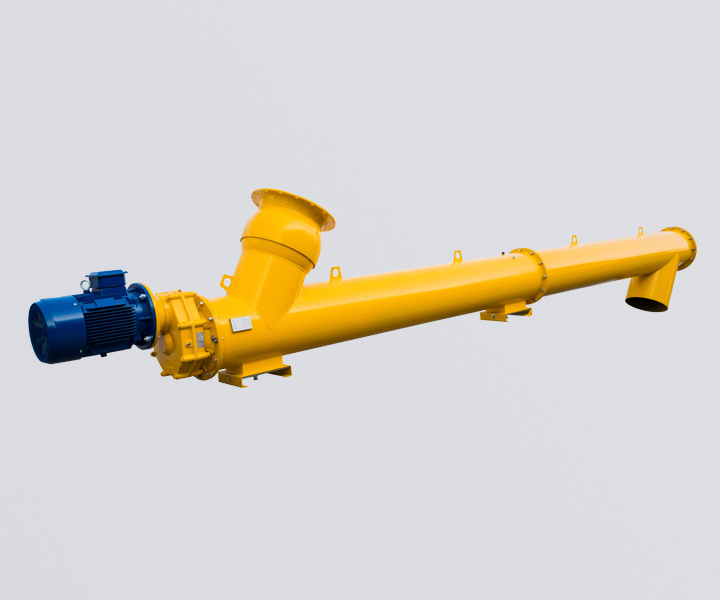

cement screw conveyor

cement screw conveyor cement screw feeder

cement screw feeder fly ash screw conveyor

fly ash screw conveyor concrete screw conveyor

concrete screw conveyor

Used to transport materials from the silo of a cement mixing plant

![]()

![]()

Price:$800.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 140-290mm

Length: 30-60 meters

Output: 20-110m³/h

Power: 2.2-30KW

Angle: 0-60°

Applicable materials: cement, coal powder, grain, fertilizer, ash, sand, coke, etc.

Application:

Cement screw conveyor is suitable for extracting, batching and conveying any type of cement, concrete, slurry, fly ash, mineral powder and other powdery and particulate materials. It is widely used in concrete mixing plants, stabilized soil mixing plants and other occasions. The cement screw conveyor can be transported horizontally or obliquely (conveying angle ≤45°). The feed port adopts a spherical feed port, which is rotatable and easy to disassemble. Its shell is connected by steel pipes through flanges to connect each section as a whole, and the overall rigidity is good. It has good airtightness, no water seepage and material leakage, and can be directly connected and fixed with its supporting equipment, without foundation, and takes up little space.

The cement screw conveyor has several applications in the construction industry for the transportation of cement and other similar materials. Here are some common applications:

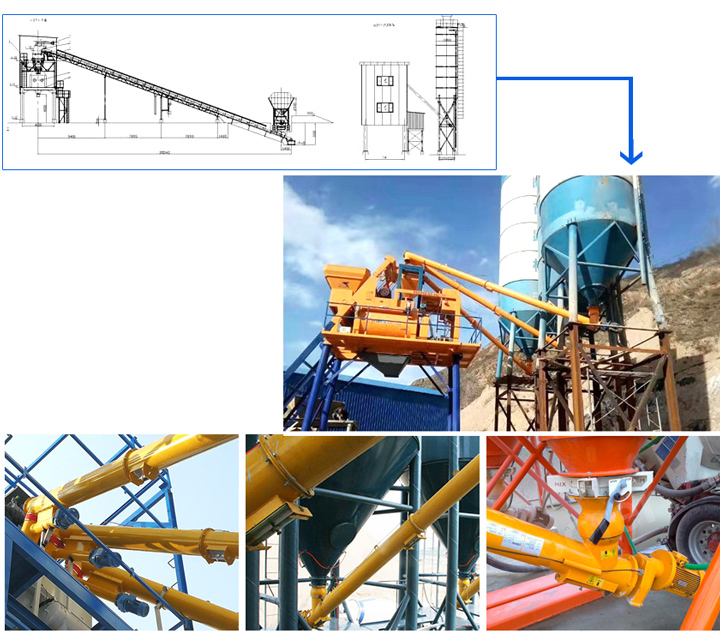

Batching plant: used to transport cement from storage silos to mixing equipment.

Concrete Mixer: It can be used to convey cement to the concrete mixer, ensuring a stable and accurate flow of materials.

Cement storage facilities: Can be used to transport cement from delivery trucks to storage silos, or from storage silos to points of use.

Bagging machine: Can be used to transport cement to bagging machine where it is packed into bags for distribution.

Construction sites: It can be used to deliver cement and other similar materials to construction sites, ensuring a stable and reliable supply of materials.

The working principle of a cement screw conveyor is based on a helical screw blade rotating inside a tube or trough. The screw blade is typically made of steel and is designed to move the material along the length of the conveyor.

Here are the steps that occur during the operation of a cement screw conveyor:

Charging: The material, such as cement, is charged into the inlet of the conveyor. The screw blade then rotates, pulling the cement into the conveyor and moving it along the length of the conveyor.

Transporting: The screw blade continues to rotate, transporting the cement along the length of the conveyor. As the cement moves through the conveyor, it is compacted and compressed by the screw blade, ensuring a smooth and even flow of material.

Discharging: When the cement reaches the discharge point, it is released from the conveyor. The discharge point can be located at the end of the conveyor, or at any point along the length of the conveyor, depending on the specific application.

Repeating: The process of charging, transporting, and discharging is then repeated as more cement is added to the conveyor.

Cement mixing station

| Model | LSY100 | LSY120 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY400 | ||

| Shell tube diameter (mm) | Φ114 | Φ133 | Φ168 | Φ194 | Φ219 | Φ273 | Φ325 | Φ402 | ||

| Angle (α) | 0°~60° | |||||||||

| Conveying capacity (m) | 8 | 10 | 12 | 14 | 15 | 18 | 20 | 25 | ||

| Conveying capacity (t/h) | 6 | 12 | 17 | 28 | 45 | 70 | 130 | 150 | ||

| Moter | Model | L≤7 | Y90S-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y132M-4 | Y160M-6 | Y160L-4 Y180M-4 |

Y180L-4 |

| Power(KW) | 1.1 | 2.2 | 3 | 5.5 | 7.5 | 11 | 15-18.5 | 22 | ||

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160M-6 | Y160L-4 Y180M-4 |

Y180M-4 Y180L-4 |

YH200L-4 | |

| Power(KW) | 2.2 | 3 | 4 | 7.5 | 11 | 15 | 18.5-22 | 20-30 | ||

Dedicated for conveying cement

The cement screw conveyor adopts a heavy-duty design gearbox, with large torque, low noise and no oil leakage

Not easy to block material

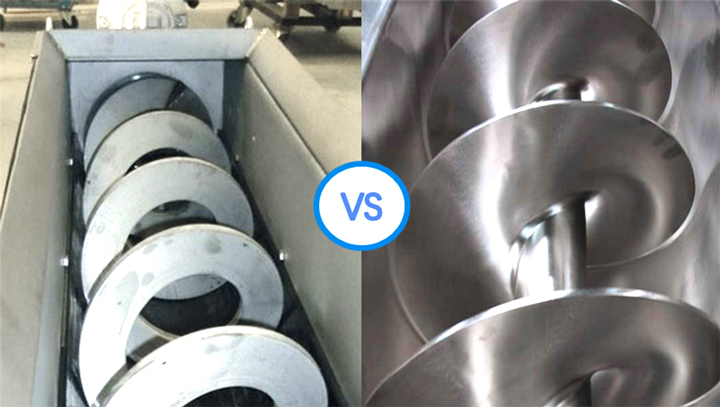

The high-precision continuous seamless spiral blade after cold hardening, the outer edge hardness reaches HB240, the double-pitch blade is formed at one time, and it is not easy to block the material

Prevent cement agglomeration

There is an anti-seepage device at the connection of the shell pipe, which can prevent the cement from agglomerating due to the infiltration of rainwater outdoors, which may cause blockage and stuffiness.

Uniform delivery

The suspended intermediate suspension bearing frame increases the material transportation space, reduces the logistics resistance, and ensures smooth, fast and uniform feeding

Cement screw conveyors have several advantages over other types of conveyor systems for the transportation of cement and other similar materials. Here are some comparisons of cement screw conveyors with other types of conveyor systems:

| Compared | Belt Conveyor | Bucket Elevator | Pneumatic Conveyors |

| Challenge | Clogging and material spillage can easily occur, resulting in downtime and maintenance costs. | Clogging and material spillage can easily occur | Can be energy intensive and require a lot of electricity to run. |

| Cement screw conveyor can solve | There is a lower risk of clogging and spillage and requires less maintenance than belt conveyors. | More energy efficient, less electricity is required to transport materials over long distances. |

For the transportation of cement slurry and cement powder, the properties and requirements of cement slurry and cement powder are different, so the following factors need to be considered when selecting:

Conveying cement slurry: Since cement slurry may corrode metal components, corrosion-resistant materials and screw conveyors with good sealing performance should be selected to prevent slurry leakage. Appropriate spiral blades can be selected according to the viscosity of the slurry. It is recommended to use a shafted screw for high humidity and a shaftless screw for cement slurry with high viscosity.

Conveying cement powder: Since cement powder is easy to agglomerate and clog, a shaftless screw conveyor can be selected to avoid the problem of powder clogging. A screw conveyor with a dustproof design can avoid the phenomenon of cement powder flying around, which helps to keep the environment clean.

The following actual cases show the wide application of cement screw conveyors in cement production, construction sites, warehousing and logistics.

Cement production plant: A cement production plant needs to transport cement powder from the production line to the warehouse for storage. To meet this demand, a shafted cement screw conveyor is installed.

Construction site: Cement needs to be transported from the ground to the high-altitude construction area at the construction site. The inclination angle is 45°. The use of shaftless equipment will not cause blockage and adhesion.

Cement storage logistics: Cement bag loading needs to be transferred and stored, 200 cubic meters per hour.

Cement production equipment: Mainly used for the transportation of cement raw materials between equipment.

Xinxiang Dahan has produced cement screw conveyors for 12 years. The cement screw conveyors have a complete range of models and can provide free selection and drawing design. It has a variety of lathes, milling machines, installation workshops, spraying workshops, warehouses and other processing workshops, as well as various cutting Machine, bending machine, polishing machine processing equipment, from design, drawing, processing, assembly, painting, quality inspection, test machine, packaging and delivery, provide one-stop service, provide 12-month quality warranty, and provide lifetime maintenance services.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.