Suitable for screening wet and dry materials, can remove oversize and contaminants and classify products into different grades according to particle size requirements

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Function: Screening, separation, sorting, sieving, grading

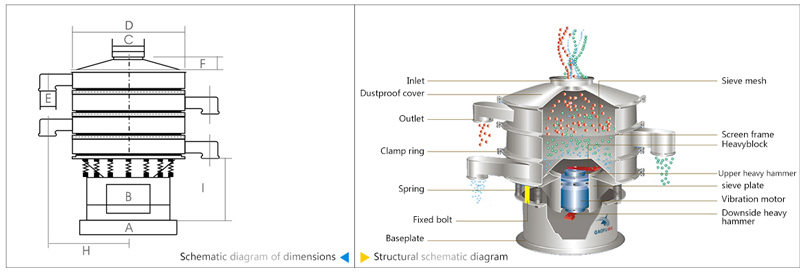

Diamater Size: 400~2000m

Screen Mesh: 2-500 Mesh

Capacity: 100Kg-10Tons/hour

Layer(s): 1-5 Layers

Noise Level: less than 80dB

Material: Carbon Steel, Stainless Steel 304/316L

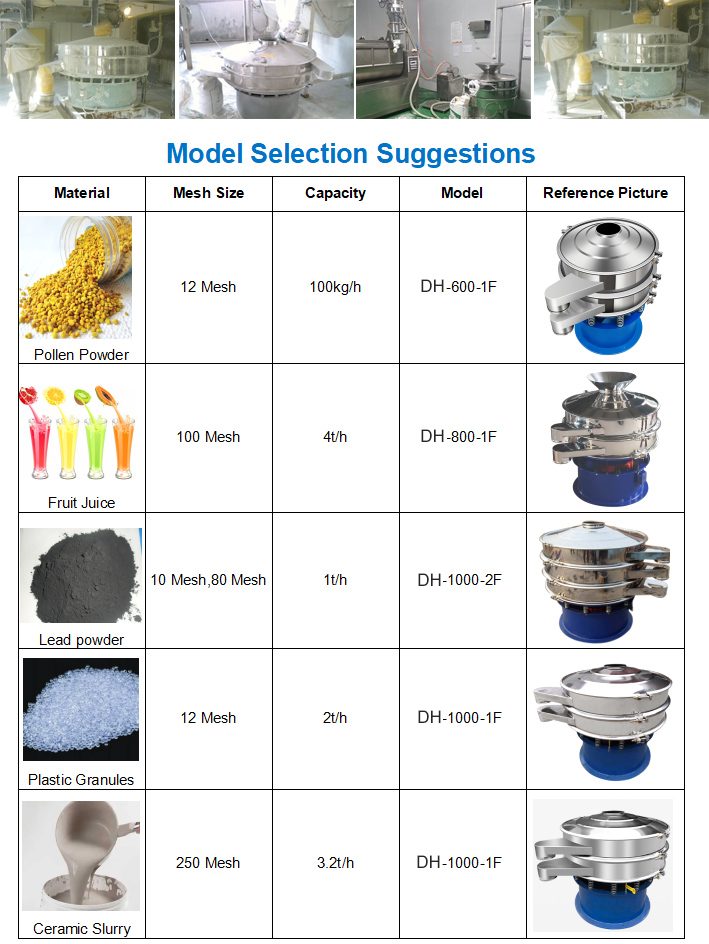

Application: Ideal for bulk screening of powders, granules and liquid slurries such as silica, ceramics, powder coatings, tapioca starch, coffee beans, copper powder, silver powder, etc.

Commitment:

Industrial vibrating sieve is suitable for screening wet and dry materials to remove oversize and contamination, and can also be used to classify different sizes within the same product, thereby improving the quality of your product. These industrial sieves are used in a variety of applications including sieving pharmaceutical powders, various food powders and powder coatings, and are also available in different sizes and options to suit your sieving requirements.

Industrial vibrating sieve can provide up to 5 grades of classification in one operation to achieve accurate particle size distribution, can sieve up to 500#, allow 100-3300kg/hour production capacity, and can be designed according to industry requirements.

Vibro Sifter

Can be used to remove broken or undersized product and can provide up to 5 grades of classification in a single operation for precise particle size distribution.Up to 6 levels of separation can be achieved.

Ultrasonic Vibrating Screen

The ultrasonic system is used to apply high-frequency vibration to the screen, which is not easy to block the screen and is suitable for ultra-fine powders with strong adsorption and high static electricity.

450 Filter Sieve

For filtering and eliminating suspended matter and unwanted particles in powders or liquids. The large-diameter discharge port automatically discharges the material quickly, and the waterproof and dustproof motor makes it safer to use.

Direct Discharge Sifter

Direct discharge discharge, suitable for screening incoming ingredients and final production inspection of finished products.The output is 2-5 times that of ordinary sieves.

Industrial vibrating sieve can screen products by using customized layered sieve and 3D motion, it can be used to screen dry powder or granular products as well as wet products and liquids, it can eliminate foreign matter in products through continuous filtration, just 1 operation It can carry out up to 5 levels of product separation, and can be used for screening, grading and solid-liquid separation in pharmaceutical, chemical, food and metal powder industries.

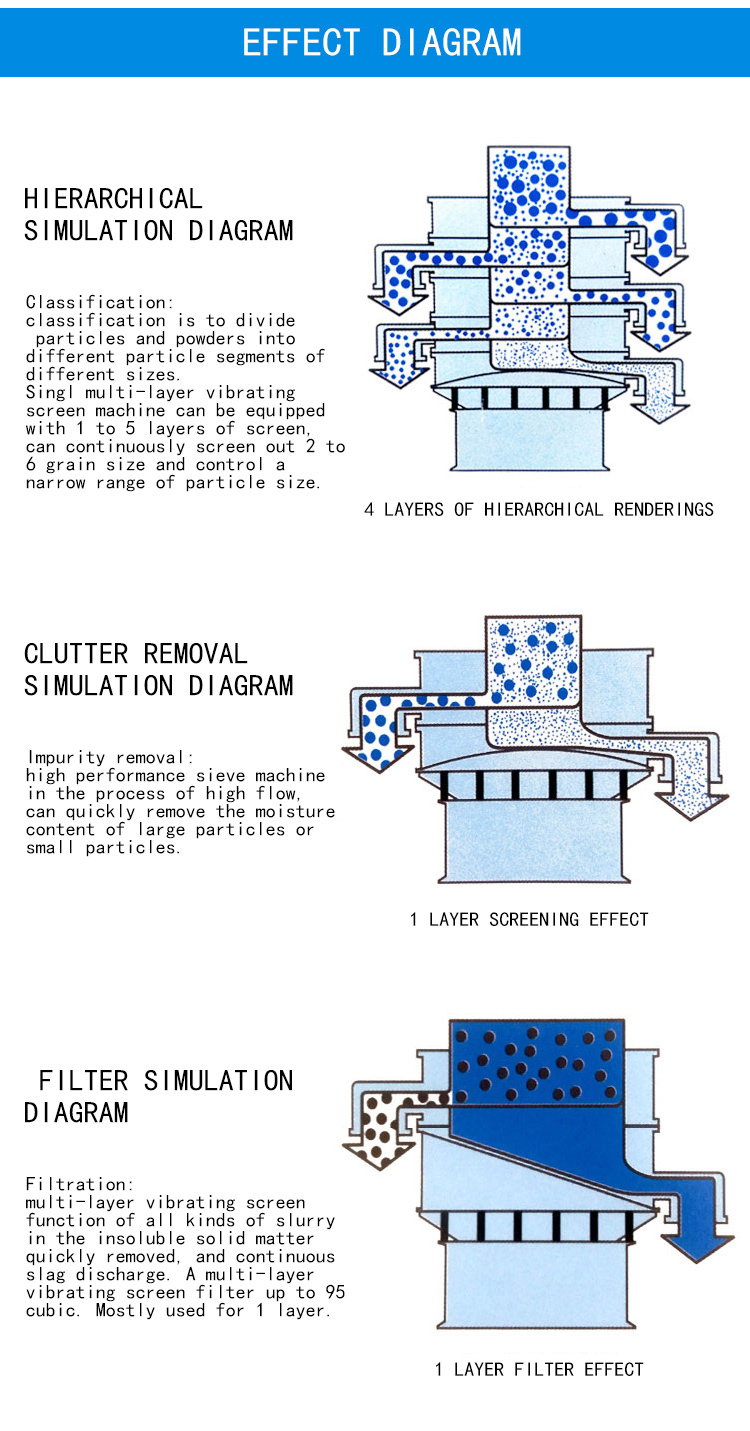

1. Remove impurities

Often a 1-layer screen, usually fine product that passes through the screen is retained as good product, and can also be used to remove broken or undersized product. In most production environments, inspection screens are either the first machine in the process to prevent contamination or the last machine before packaging machines for final quality checks.

2. Grading

Precise separation of particles of different sizes from the product so that the final material is classified into different sizes. Due to the particle size being very close to the aperture size, the throughput of classifying screens is usually much slower than that of trash screens, however, this can be compensated by a larger mesh area or fine-tuning the motor weight setting.

3. Solid-liquid separation

It can quickly remove insoluble matter in various slurries. It can filter up to 100 cubic meters per hour, and is suitable for filtering liquids such as ceramic glazes, pigments, soybean milk, and fruit juices.

Wheat bran industrial vibrating sieve

Industrial vibrating sieve for coffee beans

Improve product quality

Suitable for screening wet and dry materials, this circular vibrating screen removes oversize and contaminants to improve your product quality.

High throughput

All feed materials are automatically unloaded, and the processing capacity per hour can reach 100-3300kg.

500 mesh screening

It can sieve 500 mesh or 0.028mm powder and granules, and can also filter slurries within 5 microns

5-stage separation

Up to 5 levels of classification are available in one operation for precise particle size distribution.

Automatic cleaning

Automatic cleaning and anti-clogging device (optional bouncer, drum brush, ultrasonic cleaning device), reduce the chance of clogging the screen.

Small footprint

The compact form factor requires minimal headroom and easily fits into your existing production line.Enclosed hygienic filter ensures no dust.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Industrial vibrating sieve has diameters of 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, and can also be customized for you, such as the height of the sieve, the length of the discharge port, the addition of dust removal ports, the addition of iron removers, and the customization of materials. The size of the feed port, air tightness screening, and other special use environments and specific use conditions. It can also be used with other devices.

Sieving Flour

Small bakeries need to sift/sieve small batches of flour and some different sized ingredients before baking to make sure there are no unwanted materials in the ingredients.

Sieving Glass

Glass needs to be classified according to different particle size requirements to improve the performance of glass products.

Sievig pharmaceutical granules

Remove larger agglomerates and fine powders in pharmaceutical granules to ensure uniform and complete granules.

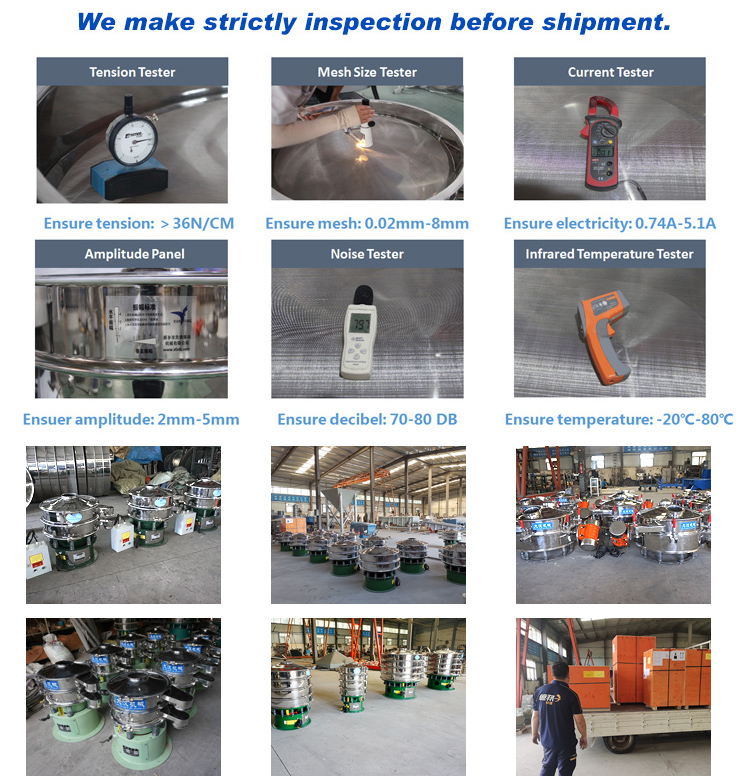

Xinxiang Dahan industrial vibrating sieve manufacturer is committed to powder, granule, liquid screening, impurity removal and filtration, providing customers with professional solutions and mature supporting products. The product sieving range covers 0-3mm coarse powder, 20-200 mesh fine Powder/granule, 400-500 mesh ultrafine powder, slurry within 5 microns. In addition, we can customize products according to actual use requirements, such as the height of the screen machine, the length of the discharge port, the addition of dust removal ports, the addition of iron removers, the customization of materials, the size of the feeding port, air tightness screening, etc. Conditions of Use. The manufacturer has obtained ISO/CE quality certification. For quality problems, the manufacturer promises that the natural damage will be refunded in full within 365 days, and the goods will be shipped within 3-7 working days.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.