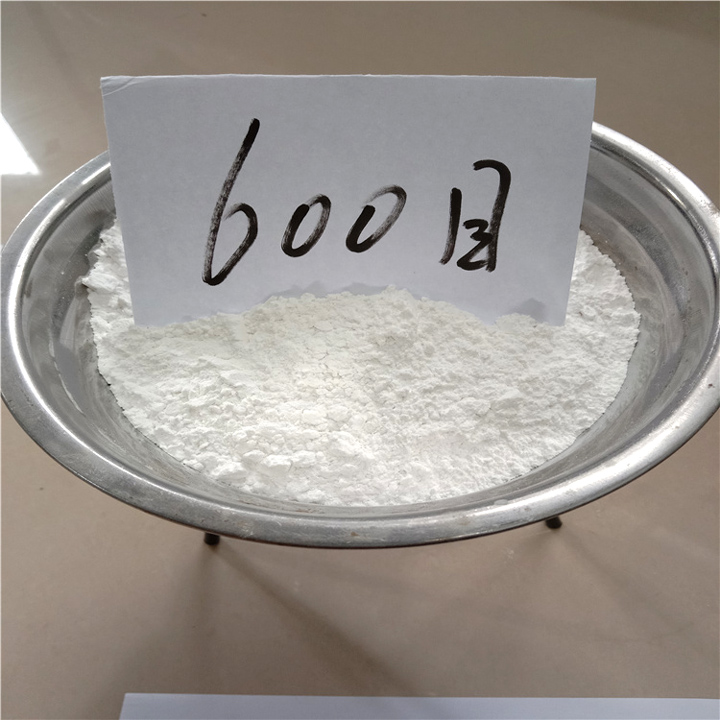

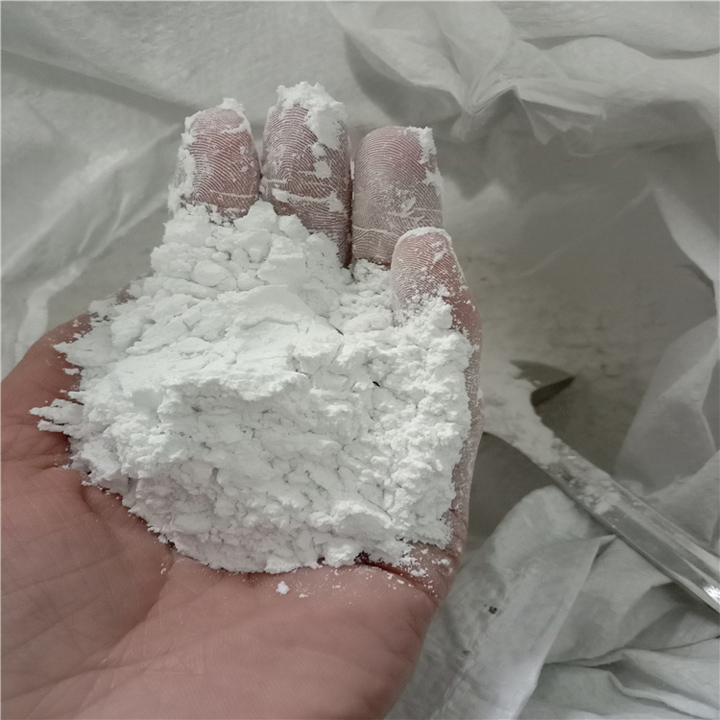

Calcium carbonate is a common inorganic compound, widely used in building materials, chemicals, medicine, food and other fields. In the production process of calcium carbonate, there are mainly light calcium carbonate and heavy calcium carbonate. The production processes in the crushing and screening of these two kinds of calcium carbonate are basically the same. Light calcium carbonate is also called precipitated calcium carbonate and light calcium carbonate.

It is obtained by chemical processing methods. Because its sedimentation volume (2.4-2.8mL/g) is larger than that of heavy calcium carbonate produced by mechanical method (1.1-1.9mL/g), it is called light calcium carbonate, limestone and other raw materials after burning. Lime and carbon dioxide, add water to digest lime to generate lime milk, and then pass carbon dioxide to carbonize lime milk to form calcium carbonate precipitation, which is then prepared by dehydration, drying and pulverization, or first use sodium carbonate and calcium chloride for metathesis reaction to generate carbonic acid Calcium is precipitated, then dehydrated, dried and pulverized.

The sieving of light calcium carbonate mainly relies on centrifugal sieve, which is a high-precision sieving equipment for mesh sieving of fine powder. Continuous screening, the screen can be replaced at will. Centrifugal screening machine (centrifugal screen) has high screening efficiency, large output, accurate fineness, no over-diameter mixing phenomenon, vertical installation of screen without load, long service life, wide range of fineness, fully enclosed structure, no dust overflow Generally speaking, the centrifugal sieve takes advantage of the characteristics of small and light powder particles, easy to float and good fluidity, and fully diffuses them into the airflow, and the powder does not Re-agglomeration, but the single particles pass through the screen in turn with the airflow, so the centrifugal screen has a large output, high efficiency, non-stick mesh, no mesh hole blocking, and accurate fineness.

When screening heavy calcium carbonate, the output is determined according to the output per hour of the manufacturer, the amount of screening is calculated according to the crushed material, plus the screening mesh required by oneself, that is, the selection of The particle size of heavy calcium carbonate depends on the particle size. Generally, the particle size of the selected material is about 100 mesh, and the main selection specifications are 60 mesh, 80 mesh, 120 mesh, etc., which are also determined according to the needs provided by users. During the screening process, linear vibrating Sieve is a good screening equipment. The screen can be replaced according to the screen set by yourself to meet your own screening requirements. The linear vibrating sieve does not mix materials, has a large sieving amount, and is easy to operate. Choose the linear vibrating sieve model. Generally, it is 1030 type, 1230 type and 1530 type. The number of layers can be selected according to the type of material to be screened, and the type of screening can be selected from 1 layer to 6 layers.

With over 12 years of experience, Dahan Machinery offers a range of vibrating sieves and separators for various industries. Dahan Machinery has a wealth of different solutions to provide customers with different solutions according to their needs, and is committed to ensuring that any unique requirements are met.

The working principle of the vibrating sieve for calcium carbonate is that when calcium carbonate particles or powder pass through the vibrating sieve, they are subjected to vibration and centrifugal force, causing them to move on the sieve. Finer particles or powders will pass through the sieve, while larger particles will be blocked on the sieve, achieving particle separation and screening. The vibration frequency and amplitude of the vibrating sieve can be adjusted to meet the requirements of calcium carbonate products with different particle sizes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.