With the continuous increase in the requirements of screening materials, the screening fineness of some powder materials can no longer meet the requirements of users with higher requirements; for example, the required fineness of materials is high, and the finer materials are more absorbent and adhesive, etc., vibration The biggest problem is that the sieve hole blockage reduces the sieving efficiency. During screening, various forms of sieve hole blockage will occur according to the properties of the material particles. The main points are as follows:

1. Contains a large number of particles close to the separation point.

2. Materials with moisture or hygroscopicity on the surface; the lateral force adjustment of the motor is large, and the longitudinal force adjustment is small.

3. Spherical particles or materials with multiple contact points to sieve holes.

4. The material particle density is small.

5. Static electricity can occur; at this point, the bottom thread can be connected to handle static electricity.

6. Good filling material.

7. When the material has fibrous particles and other particle shapes with embolism.

Because most of the material particles that need to be screened are irregular, there are various reasons for clogging. In order to effectively prevent the mesh from being blocked, measures should be taken according to the above-mentioned sieve hole blocking conditions, such as the installation of bouncing ball cleaning devices (such as vibro sifter, bouncing balls installed on the mesh frame in the linear vibrating screen, etc.), and ultrasonic cleaning devices. (Ultrasonic vibrating screen), wind cleaning device (centrifugal screen).

The blocking mesh solved by the ultrasonic vibrating screen is generally based on the high screening fineness, the material is mainly adsorbable, and the material with a relatively light specific gravity can also choose an ultrasonic vibrating screen or an ultrasonic vibrating screen according to the screening weight. Automatically track the co-vibration point of the ultrasonic vibrating screen. In addition to the basic vibration function of the general three-dimensional vibrating screen, high-frequency ultrasonic vibration is superimposed on the mesh surface, which changes the incompatibility and inability to adjust the vibration frequency of the previous vibrating screen. . While the screen is subjected to low-frequency vibration of the vibration motor, ultrasonic high-frequency vibration is superimposed on the surface of the screen, so that the large particles on the screen are suspended on the surface of the screen, which completely avoids the blockage of the screen. It solves the technical problems such as static electricity, easy agglomeration, strong adsorption, and blocking of screen meshes that cannot be handled by ordinary vibrating screens. The throughput and output of materials that are traditionally difficult to screen as well as ultra-fine materials have been significantly increased.

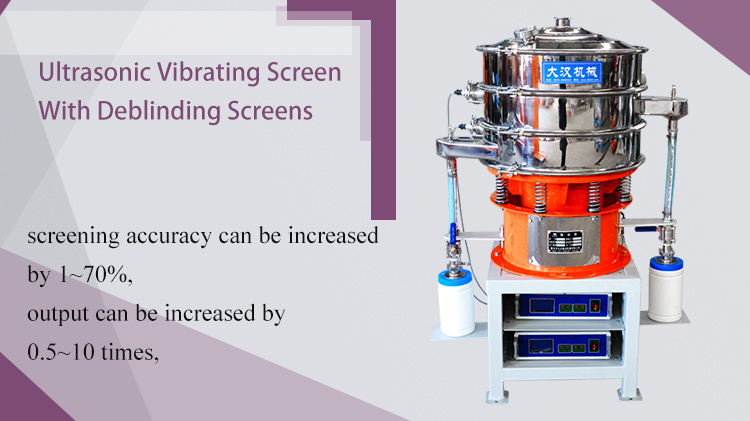

Ultrasonic vibrating screen features

1. In addition to horizontal, inclined and vertical three-dimensional motion, the mesh surface produces superimposed ultrasonic vibration.

2. There is no mesh blockage, and there is a complete self-cleaning function of the screen. The smallest screen is 625 mesh (18 microns).

3. Really solve the difficult screening phenomenon caused by static electricity, agglomeration, strong adsorption, etc., and can achieve effective screening with high mesh.

4. Ensure that the properties of the processed materials remain unchanged.

5. The screening accuracy can be increased by 1~70%, and the output can be increased by 0.5~10 times, especially for difficult-to-screen materials.

Ultrasonic vibration wave is a vibration wave greater than 20,000 Hz. In the ultrasonic vibrating screen, we generally use the frequency band between 30,000-40,000 Hz. Its vibration characteristics are: the mesh wire generates a sinusoidal longitudinal propagating sound wave with strong penetrating ability and greater than 20,000 times at a small amplitude, and bounces off the material adhering to the screen, so as to prevent the material from clogging the screen. the goal of.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.