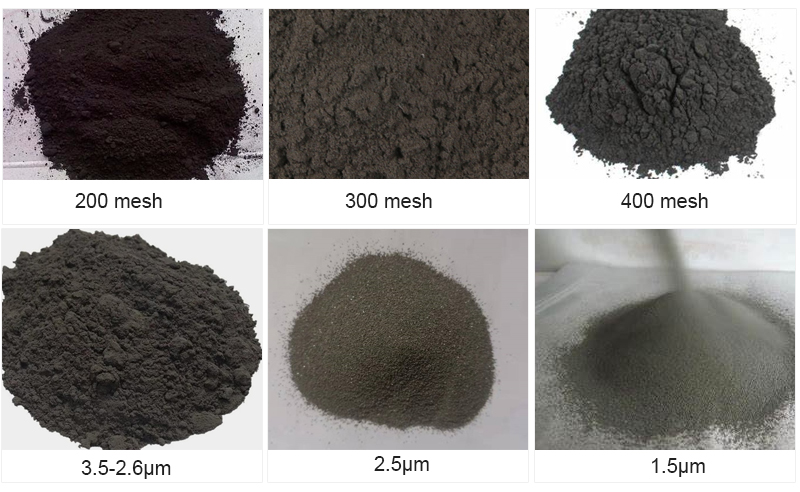

Tungsten powder uses tungsten oxide as raw material, and is reduced with hydrogen in a four-tube muffle furnace or multi-tube furnace, and the particle size is from 0.6 to 30 microns. Mainly divided into coarse, medium and fine particle size, silver-gray powder, impurity content is based on national standards.

Tungsten powder particles refer to tungsten powder particles formed by sintering tungsten powder to form tungsten lumps such as rods, and then crushed. Tungsten powder particles are distinguished by mesh number. The applications of tungsten powder particles include alloy powder catalysts, etc.

The particle size distribution of tungsten powder is critical to its performance in various applications. Ultrasonic vibrating screens can be used to precisely control the particle size distribution of tungsten powder. By selecting the appropriate mesh size and adjusting the vibration intensity and frequency to achieve the required Classification, where segregation occurs due to differences in particle size and density, which results in uneven powder distribution. By classifying the powder with vibrating sieves prior to storage and transport, the powder can be distributed more evenly and the risk of segregation can be reduced. In addition, tungsten powder may contain impurities and foreign matter, which will affect its performance in various applications. Vibrating screens can effectively remove impurities and foreign matter in tungsten powder to ensure that the powder meets the required specifications.

Ultrasonic vibrating screen is usually used for grading of tungsten powder, which is easy to solve: the material has strong adsorption (easy to stick to the net), the material is easy to agglomerate, has static electricity (easy to stick together), the material is easy to absorb moisture (easy to block the net), light specific gravity The screening problem of materials. While the ultrasonic vibrating screen is subjected to the low-frequency vibration of the vibration motor, the ultrasonic high-frequency vibration is superimposed on the surface of the screen, so that the large particles on the screen are suspended on the surface of the screen, and the mesh of the screen is prevented from being blocked.

For more detailed information, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.