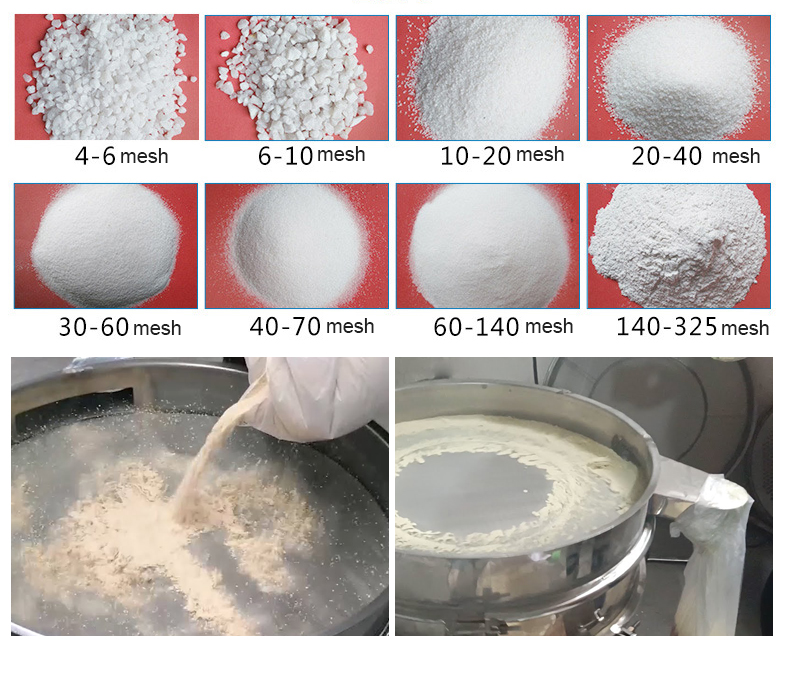

Quartz powder, also known as silicon micropowder, is a hard, wear-resistant and chemically stable mineral, which is made by grinding quartz sand into powder. Quartz sand and quartz powder have the same composition and different particle sizes. Generally, we call the coarse powder of 120 mesh as quartz sand, and the fine powder of 120 mesh as quartz powder. Vibrating screen is an indispensable separation equipment in the preparation process of quartz sand, and in the preparation process of quartz powder, vibrating screen is also indispensable. At present, there are two main preparation methods of quartz sand: dry method and water method. The processing steps of the two are different, but the general process is to crush the quartz sand raw material and then use an ultrasonic vibrating screen for particle size classification and screening.

We have introduced in the product introduction of quartz sand vibrating screen before that linear vibrating screen is the main model for screening quartz sand, but is this model also applicable for powdered quartz powder? Dahan Machinery is here to ask Remind you, powder materials and granular materials in the process of grading and screening due to the large difference in material particle size, the requirements for the screening mesh of the vibrating screen are quite different. For example, the main specifications and standards of quartz sand are 3- 4 mesh, 5-7 mesh, 8-12 mesh, 12-26 mesh, 26-50 mesh, 100-150 mesh; the main meshes of quartz powder are 200 mesh, 240 mesh, 300 mesh, 320 mesh, 340 mesh, 400 mesh of these. It is difficult to ensure the particle size accuracy of quartz powder if there is no distinction in the selection of models. In addition, fine powder materials are prone to fly and suspend light powder during the screening process, while the linear vibrating screen phase Compared with professional powder vibrating screen, it does not have obvious advantages in sealing.

Sieving quartz powder can pose some challenges due to the unique properties of the material. Some of the challenges of sieving quartz powder are:

1. Static electricity: Quartz powder is a highly charged material that can generate static electricity during the sieving process. This can cause the particles to stick to the screen mesh, making it difficult to achieve efficient separation.

2. Agglomeration: Quartz powder particles tend to agglomerate or clump together due to their high surface energy. This can cause blockages in the sieve mesh and reduce the efficiency of the sieving process.

3. Abrasiveness: Quartz powder is a hard and abrasive material that can cause wear and tear on the sieve mesh, reducing its lifespan and leading to increased maintenance costs.

4. Dust generation: The sieving of quartz powder can generate a significant amount of dust, which can pose a health hazard to workers and contaminate the surrounding environment.

5. Particle size distribution: The particle size distribution of quartz powder can be challenging to control, as the particles tend to have irregular shapes and sizes. This can lead to difficulties in achieving precise classification and separation.

After the above analysis, Dahan vibrating screen manufacturer suggests that the ultrasonic vibrating screen is more suitable for the screening of quartz powder, which can accurately screen powdery materials within 500 mesh. The cleaning device of this series of screen machines uses an ultrasonic system. The sieve surface will form a high-frequency low-amplitude ultrasonic vibration wave, so that the high-fine powder is suspended on the sieve surface at a low altitude, so as to realize the net cleaning and solve the problem of blocking the net, and the production capacity can be increased by 10 times.

In the preparation process of quartz powder, since the raw materials are often mixed with iron-containing impurities, if not removed, the product quality of quartz powder will be greatly reduced and its use value will be reduced. Therefore, the iron removal process in the process of quartz powder is necessary and important. Dahan vibrating screen manufacturers can effectively carry out additional iron removal treatment on the sieved quartz powder by installing an iron remover at the discharge port of the quartz powder ultrasonic vibrating screen, greatly reducing or even eliminating the iron-containing impurities in the finished quartz powder. While ensuring that the particle size of the quartz powder meets the standard, the quality of the quartz powder can be effectively improved, thereby saving the time cost and equipment cost of additional magnetic separation.

For more information, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.