The fly ash screw conveyor can realize the precise conveying control of fly ash, ensure the batching accuracy, and at the same time recover the remaining fly ash in the screw conveyor, reducing the risk of pipeline blockage

1. The continuous spiral blades are made of imported high-strength wear-resistant steel. After molding, the pitch error is less than 5mm, and the blade surface is smooth, which ensures the uniformity and stability of material transportation and the repeatability of material measurement.

2. Since the conveying process is carried out in a closed pipeline, there is basically no dust pollution, and the conveyed materials will not leak, which improves the working environment.

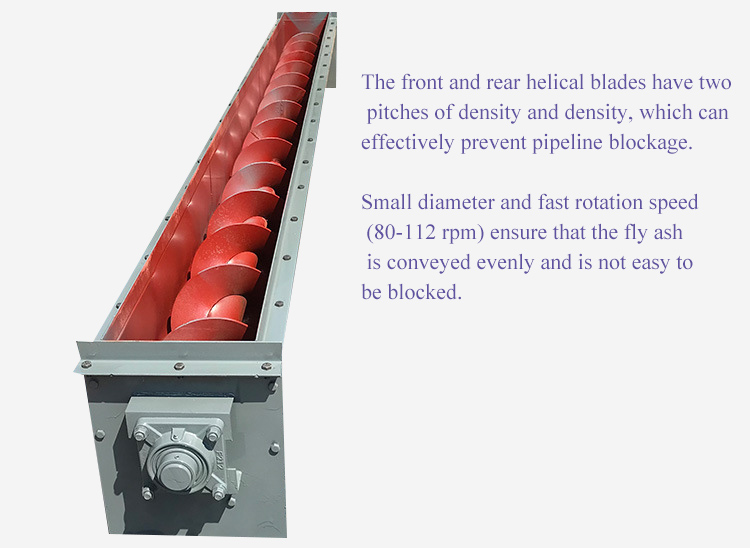

3. The front and rear helical blades have two pitches of density and density, which can effectively prevent pipeline blockage. Small diameter and fast rotation speed (80-112 rpm) ensure that the fly ash is conveyed evenly and is not easy to be blocked.

4. The connection between the feeding port and the cement silo port is divided into two forms: rigid connection of universal ball flange and flexible connection of hanging waterproof canvas.

The diameter of the fly ash screw conveyor includes 140/165/219/273/325/426mm, and the length can reach 1-20 meters. It can transport fly ash, concrete, cement powder and other products horizontally or inclined (<50 degrees).

1. Uniquely designed spiral blade: The spiral blade is the core component of the fly ash screw conveyor. Its design affects the transportation efficiency and the wear degree of the material. The shape of the spiral is usually equidistant or variable-pitch spiral to adapt to the transportation needs of different materials. Considering the abrasiveness of fly ash, spiral blades are usually made of wear-resistant alloy steel or wear-resistant rubber to extend their service life.

2. Sealing casing: Fly ash has strong fluidity and dust characteristics, so sealing is crucial. The casing often uses packing seals, labyrinth seals, etc. to effectively prevent dust leakage and improve the working environment.

3. Bearing selection and arrangement: Bearing selection and arrangement directly affect the smooth operation and service life of the screw conveyor. Rolling bearings or sliding bearings are commonly used, usually arranged at the head, middle and tail of the casing to support the spiral shaft and reduce vibration.

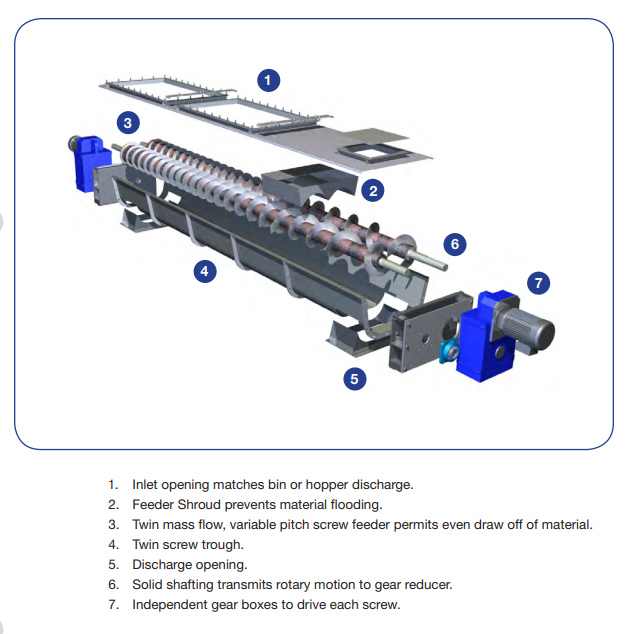

4. Configuration of the driving device: The driving device provides power for the screw conveyor, and its configuration directly affects the conveying efficiency. Select the appropriate motor power and speed according to the conveying volume and material characteristics. The reducer converts the high-speed rotation of the motor into the low-speed and high-torque rotation of the screw shaft.

Fly ash enters the conveyor trough of the screw conveyor through the feed port. The feeding method can be direct pouring, funnel feeding or even feeding through other feeding equipment. Driven by the spiral blades, it moves forward along the axis of the cylinder. During this process, there is a certain amount of friction between the material and the spiral blades, which allows the material to adhere tightly to the blades, thereby being pushed to the discharge port and finally discharged.

Structural Characteristics of Fly Ash Screw Conveyor is simple and compact, with good sealing performance, and it can meet the conveying requirements of fly ash a certain extent. The diameter of the powder is 140/165/219/273/325/46mm, and the length can reach 1-20 meters. It can convey fly ash, concrete, cement powder, etc. horizontally or at an incl (<50 degrees). However, during the use process, reasonable selection, installation, operation, and maintenance must be carried out according to the actual situation to ensure stable operation and efficient conveying of the equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.