We mentioned in the previous article that belt conveyors are a good choice when conveying concrete aggregates, so where are screw conveyors mainly used?

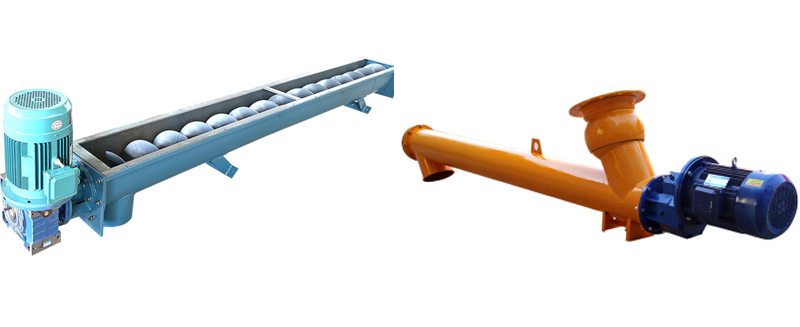

The screw conveyor used for conveying concrete can be called cement screw conveyor. The main purpose is to transport dry and wet cement and fly ash. Compared with ordinary screw conveyors, concrete screw conveyors are also different in structure.

Compared with ordinary conveying equipment, the biggest difference between concrete screw conveyor is its variable pitch design, universal ball or cloth bag feeding connection and anti-seepage water treatment.

1. Variable pitch design: the overall torque is increased, the pitch of the upper part is larger than that of the lower part, so you can eat less and spit faster to prevent clogging;

2. Flexible connection port: the universal ball and bag feeding connection port can be selected according to the frequency of disassembly, and the flexible structure ensures that the feeding equipment is tightly connected;

3. Anti-seepage device: It can work normally in rainy days to prevent the infiltration of rainwater and cause cement agglomeration.

The advantages of choosing a screw conveyor for conveying concrete:

1. It is transported in the pipeline, less affected by the outside world, and the quality of the raw materials is better;

2. The length of a single machine can reach 60 meters, and the conveying capacity can reach 458 cubic meters per hour, with good benefits;

3. Compact structure, small footprint, support for large-angle inclined transportation, and flexible layout of the construction site.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.