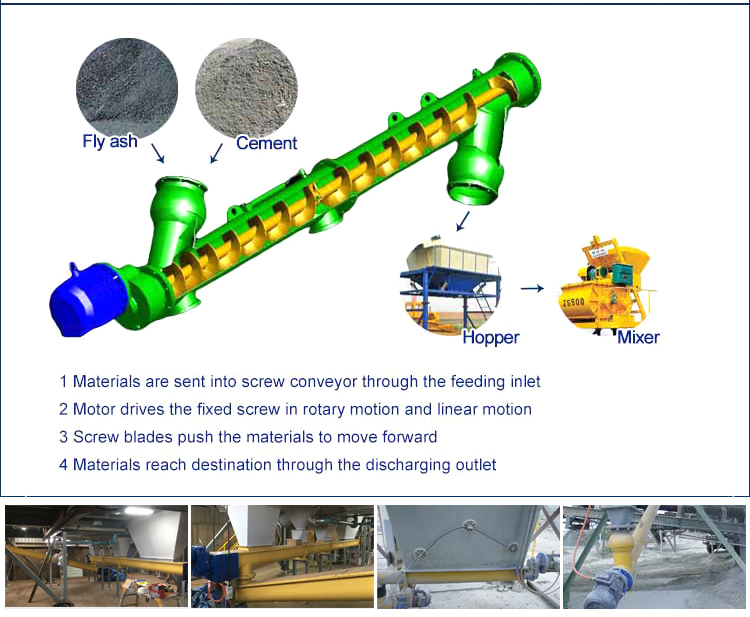

Realize the precise conveying control of fly ash, ensure the proportioning accuracy, and at the same time recover the fly ash remaining in the screw conveyor to reduce the risk of pipe blockage

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Pipe diameter: 114-400m

Conveying length: 2-12 meters

Capacity: 54-75 t/h

Conveying angle: 0-60 degrees

Speed: 80-112 RPM

Application: Fly ash can be extracted from below the storage hopper of the power plant, efficient and dust-free loading

Power: 15.4-18 KW

Commitment:

The fly ash used in the concrete batching plant is transported by the fly ash screw conveyor. By controlling the rotation and stop of the screw blades, the feeding control of the powder products is achieved. The fly ash screw conveyor is a circular casing, Movable conveyors are mostly used for large inclination conveying, so their conveying principle is different from that of grooved screw conveyors. When the helix rotates at an angular velocity, the material on the surface of the helical blade also rotates due to the action of friction. When the angular velocity reaches a certain value, the material is thrown obliquely forward along the helical surface and attached to the casing. The material is continuously advanced.

The commonly used diameters of fly ash screw conveyors are 165mm, 219mm, 273mm, 323mm, 407mm, and the feeding port adopts spherical feeding port, which can be rotated and easy to disassemble. Sealing, prevent dust pollution, can be conveyed horizontally or inclined according to the user's conveying process, the combination is flexible, and it can be used with a variety of equipment.

The main sources of fly ash are thermal power plants and urban central heating boilers fueled by pulverized coal, of which more than 90% are wet ash discharge, which is less active than dry ash, and costs water and electricity, pollutes the environment, and is not conducive to comprehensive use. In order to better protect the environment and facilitate the comprehensive utilization of fly ash, considering the maturity of dust removal and dry ash conveying technology, dry ash collection has become the development trend of fly ash collection in the future. Our company specializes in developing a fly ash screw conveyor with low cost and excellent quality. It is mainly used in concrete mixing plants (buildings), asphalt mixing buildings, and dry mortar production lines to transport cement, fly ash, mineral powder, dry mortar and other materials. Effect.

Even delivery

The continuous spiral blade is made of imported high-strength wear-resistant steel. After forming, the pitch error is less than 5mm and the blade surface is smooth, which ensures the uniformity and stability of material conveying and the repeatability of material measurement.

Not easy to dust

Because the conveying process is carried out in a closed pipeline, there is basically no dust pollution, and the conveyed materials will not leak, which improves the working environment.

Not easy to block

The front and rear helical blades have two pitches of sparse and dense, which can effectively prevent the pipe from being blocked. The small diameter and fast rotation speed (80-112 RPM) ensure that the fly ash is transported evenly and is not easy to be blocked.

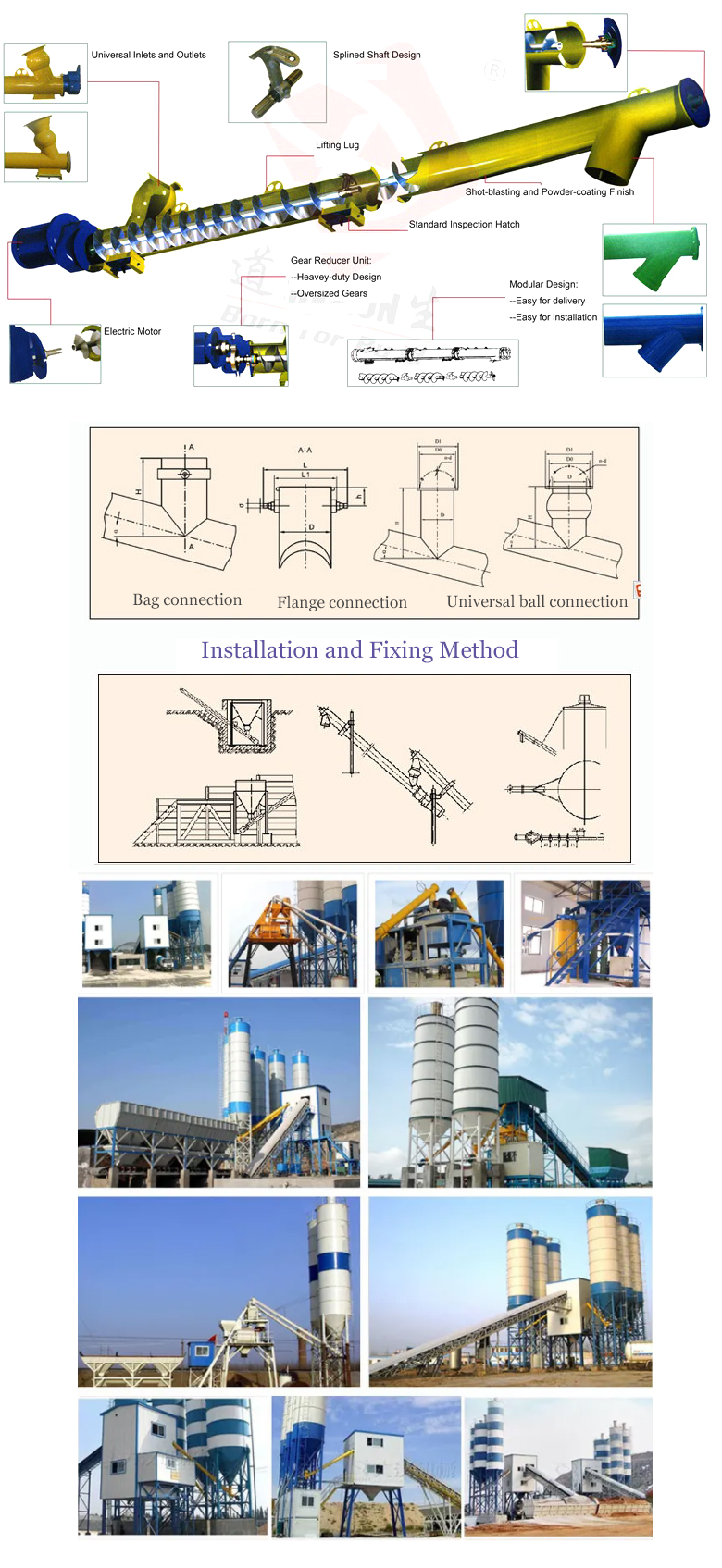

Multiple link methods

The connection method between the feeding port and the cement silo port is divided into two forms: rigid connection with universal ball flange and flexible connection with hanging and waterproof canvas. The frequency of disassembly and assembly of visual equipment determines the interface form.

| Model | LSY100< | LSY120 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY400 | ||

| Tube Diameter (mm) | Φ114 | Φ133 | Φ168 | Φ194 | Φ219 | Φ273 | Φ325 | Φ402 | ||

| Angle (α) | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | ||

| Conveying Length (m) | 8 | 10 | 12 | 14 | 15 | 18 | 20 | 25 | ||

| Conveying Capacity (t/h) | 6 | 12 | 17 | 28 | 45 | 70 | 130 | 150 | ||

| Motor | Model | L≤7 | Y90S-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y132M-4 | Y160M-6 | Y160L-4 | Y180 |

| Y180M-4 | L-4 | |||||||||

| Power KW | 1.1 | 2.2 | 3 | 5.5 | 7.5 | 11 | 15-18.5 | 22 | ||

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160M-6 | Y160L-4 | Y180M-4 | YH20 | |

| Y180M-4 | Y180L-4 | 0L-4 | ||||||||

| Power KW | 2.2 | 3 | 4 | 7.5 | 11 | 15 | 18.5-22 | 20-30 | ||

Note: The conveying capacity in the above table is the conveying capacity when the bulk density of fly ash is 0.6t/m3 and the conveying angle is 30°~45°.

In addition: Generally, the fly ash screw conveyor is used for the complete set of equipment of the manufacturer. As a matching product, the fly ash screw conveyor has stock in stock, but for different users or different occasions, the user needs to provide the conveying length (or the oblique length of the import and export). ), elevation angle, customized by the manufacturer according to user requirements.

Fly ash screw conveyor consists of electric motor, reduction box, input section assembly, intermediate section and intermediate support body assembly, output section assembly, front support body assembly, oil filling and lubrication system, and accessories are cables and connection canvas covers , Hanging wire rope and accessories.

1. The overall torque is larger and the variable pitch design is adopted. The pitch of the lower half is smaller than that of the upper half, which can effectively prevent cement blockage.

2. The continuous helical blade is made of cold work hardened surface cold rolling treatment, the hardness and wear resistance are about doubled compared with ordinary blades, and the outer edge hardness can reach HB240.

3. There is an anti-seepage device at the connection of the shell, which can avoid the infiltration of rainwater and cause the cement to agglomerate and cause material blocking.

4. Suspended hanging bearing frame, the material transportation space is increased, and the resistance of cement transportation is reduced.

5. The connection method between the feeding port and the cement silo port is divided into two forms: rigid connection with spherical hinge flange and flexible connection with hanging and waterproof canvas. The frequency of disassembly and assembly of visual equipment determines the interface form.

The advantages of the two connection methods are that more subtle and variable direction adjustments can be made, and the fly ash feeding and discharging devices can be more closely adapted and connected.

| Bag Connection Method | |||||||||

| Size | LSY100-200 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY350 | LSY400 | |

| D | 114(133) | 168 | 194 | 219 | 273 | 325 | 355 | 402 | |

| d | 20 | 20 | 30 | 30 | 36 | 36 | 36 | 40 | |

| d1 | M16 | M16 | M20 | M20 | M24 | M24 | M24 | M30 | |

| d2 | 20 | 20 | 30 | 30 | 36 | 36 | 36 | 40 | |

| L | 223 | 249 | 294 | 319 | 403 | 455 | 485 | 542 | |

| L1 | 157 | 179 | 218 | 243 | 303 | 355 | 385 | 432 | |

| h | 60 | 60 | 70 | 70 | 90 | 90 | 90 | 90 | |

| H | α≤30° | 200 | 250 | 300 | 350 | 400 | 500 | 500 | 600 |

| 30°<α≤45° | 250 | 300 | 350 | 400 | 500 | 550 | 550 | 650 | |

| 45°<α≤60° | 300 | 350 | 400 | 500 | 550 | 600 | 600 | 700 | |

| Flange Connection Method | |||||||||

| Size | LSY100 200 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY350 | LSY400 | |

| D | 114(133) | 168 | 194 | 219 | 273 | 325 | 355 | 402 | |

| D0 | 160 | 200 | 225 | 252 | 315 | 365 | 395 | 460 | |

| D1 | 190 | 230 | 260 | 285 | 350 | 400 | 430 | 500 | |

| H | α≤30° | 200 | 250 | 300 | 350 | 400 | 500 | 500 | 600 |

| 30°<α≤45° | 250 | 300 | 350 | 400 | 500 | 550 | 550 | 650 | |

| 45°<α≤60° | 300 | 350 | 400 | 500 | 550 | 600 | 600 | 700 | |

| n-d | 6-Φ11 | 6-Φ11 | 8-Φ11 | 8-Φ13 | 8-Φ17 | 8-Φ19 | 8-Φ19 | 8-Φ19 | |

| Universal Ball Connection Method | |||||||||

| Size | LSY100 200 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY350 | LSY400 | |

| D | 114(133) | 168 | 194 | 219 | 273 | 325 | 355 | 402 | |

| D0 | 200 | 250 | 250 | 300 | 365 | 365 460 |

385 460 |

460 | |

| D1 | 225 | 278 | 278 | 328 | 400 | 400 500 |

430 500 |

500 | |

| H | α≤30° | 400 | 400 | 450 | 450 | 550 | 650 | 650 | 700 |

| 30°<α≤45° | 450 | 450 | 500 | 550 | 600 | 750 | 750 | 800 | |

| 45°<α≤60° | 450 | 500 | 550 | 600 | 650 | 800 | 800 | 900 | |

| 50°<α≤55° | 500 | 500 | 600 | 650 | 700 | 900 | 900 | 950 | |

| 55°<α≤60° | 550 | 550 | 650 | 700 | 800 | 1000 | 1000 | 1100 | |

| n-d | 6-Φ11 | 6-Φ11 | 8-Φ11 | 8-Φ13 | 8-Φ17 | 8-Φ19 | 8-Φ19 | 8-Φ19 | |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.