The shaftless screw conveyor has no central shaft, and is suitable for conveying materials that cannot or cannot be conveyed by the shafted screw conveyor, such as granular materials, paste materials, semi-fluid and viscous materials, and easily entangled materials.

Mainly used in sewage treatment, garbage recycling, widely used in chemical, food, medicine, paper, beverage and other industries to convey strong adhesion, paste-like viscous materials (such as chemical raw materials, waste paper pulp, malt, sludge, etc.) winding material (such as household waste).

1) The conveyed material will not tangle or stick

There is no risk of clogging due to material sticking to the shaft, residues and pulper residue can be easily transported.

2) Can be used on steep slopes

Conveying material The material can be conveyed on a slope angle of 0 to 25 degrees, and the conveyor can be installed in a narrow space.

3) Various connections are possible.

There are no restrictions on the type of connection between equipment without bearings at the conveyor end and can be designed to fit space constraints or plant layouts.

4) Low noise

When the material is conveyed on the resin liner at low rotational speeds, the noise level is low, and the wear of the resin liner is reduced as the conveyed material becomes a lubricant (self-lubricating).

5) Completely sealed

The conveyed material has no odor or spillage issues, greatly reducing labor for routine maintenance and cleaning.

6) Materials can be transported over long distances

One screw can transport materials up to a distance of 32m without adjusting the belt tension, which greatly reduces daily maintenance.

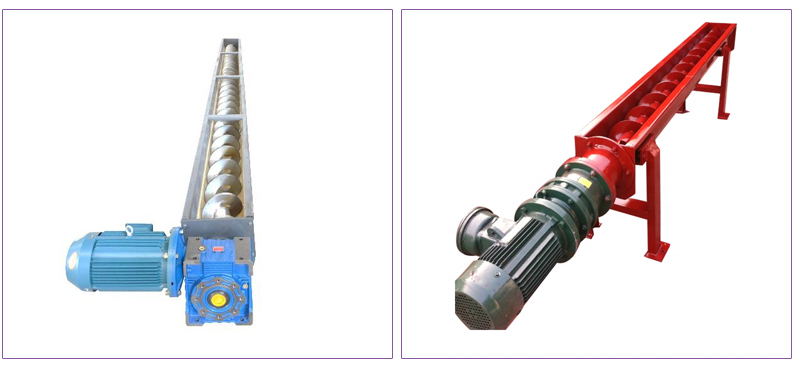

1. Application: For viscous, pasty and sticky products, the solution is shaftless screw conveyor, while solid material powder, grain and seeds are generally handled by shafted screw conveyor.

2. Length: Shafted screw conveyors can be longer, in most applications, hanging bearings or bushings are used every 3 meters, but this hinders the flow of material on large capacity conveyors. The shaftless screw conveyor is connected with the whole machine, without hanging bearing, and the conveying length can reach more than 10 meters. Typically, a 3 meter length of casing is connected in series to form the user's length.

3. Filling rate: Shaftless screw conveyors can have a higher filling rate, about 35%-40%, without hanging bearings. For applications such as live bottom hoppers and controlled feeding, shaftless screw conveyors are selected. Due to the need for hanging bearings, shaft screw conveyors have a low slot fill rate of about 15%-30%.

4. Maintenance: The shaftless screw conveyor does not need a lining plate in the groove or the round pipe, thereby reducing maintenance work, while the shaftless screw conveyor is a component, and due to the rotation of the screw conveyor, the lining plate needs to be removed and installed. replace. Contact or friction, it wears out over time, which is often a problem if the screw conveyor is in high or inaccessible locations.

Our shaftless screw conveyors provide a non-clogging conveying surface that makes difficult-to-convey materials easy to convey, a solution for handling high moisture content, viscous, entangled bulk materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.