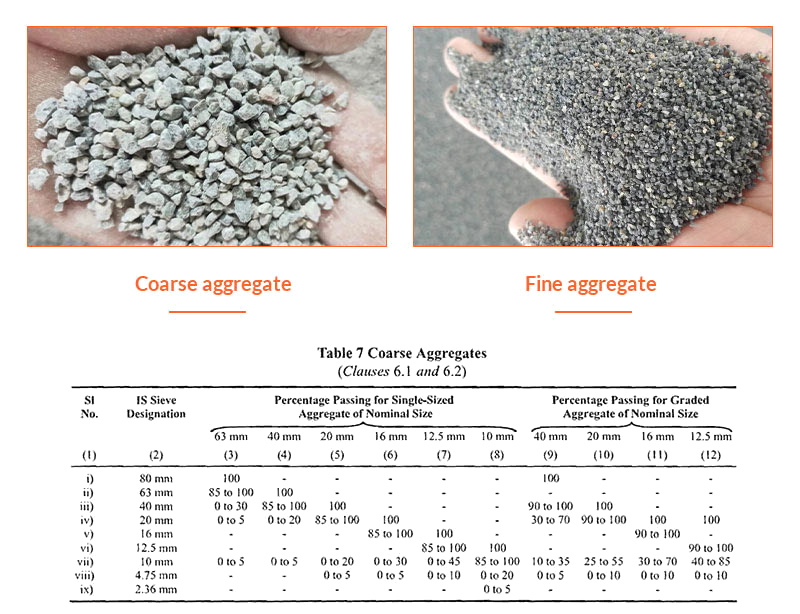

A test used to determine the particle size of fine and coarse aggregates, helping to ensure aggregates are of uniform size and quality

![]()

![]()

Price:$20.00 - $200.00/Set

Consult now and enjoy a 10% discount

Diameter: 100mm, 200mm, 300mm

Specifications: 2.36mm, 4.75mm, 9.50mm, 16.0mm, 19.0mm, 26.5mm, 31.5mm, 37.5mm, 53.0mm, 63.0mm, 0.75mm, 90.0mm.

Material: stainless steel

Hole shape: round hole, square hole, diamond hole

Weight: 45kg

Applications: Materials such as sand, gravel and crushed stone are used in the construction industry for various applications such as making concrete, asphalt and roads.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

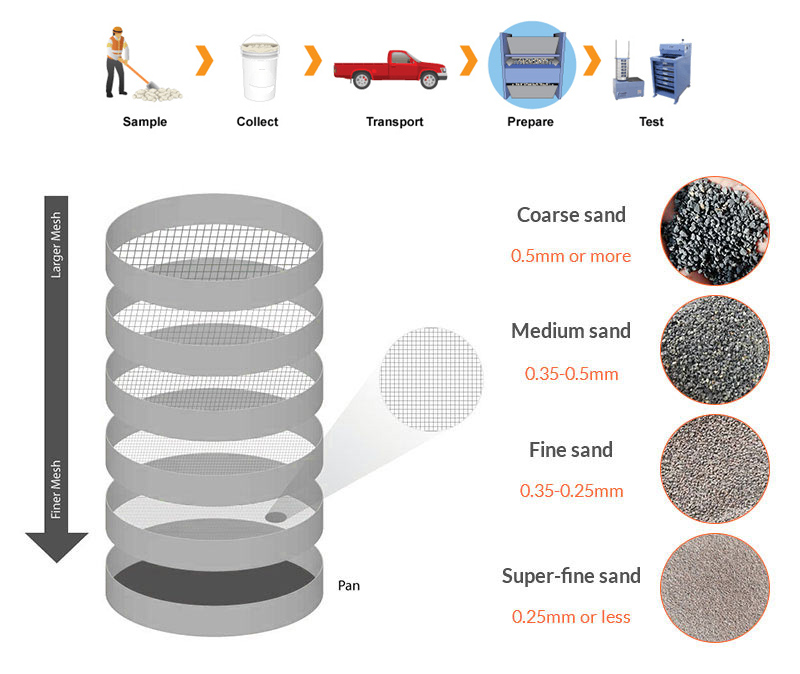

Sieve analysis of aggregates is a process used to determine the particle size distribution of coarse and fine aggregates (such as sand, gravel, crushed stone, and recycled concrete). The analysis is performed by passing a sample of the aggregate through a series of sieves of progressively smaller mesh size. The sieves are arranged in order of decreasing mesh size, with the largest aperture at the top and the smallest at the bottom. The sample is shaken for a specified time and the amount of material retained on each sieve is weighed. The results of the sieve analysis are used to determine the particle size distribution of the aggregate.

1. Graded crushed stone refers to containing only crushed stone, that is, coarse aggregate in concrete, excluding sand (fine aggregate), which is determined according to the laboratory ratio test and is composed of various particle sizes. Mixture of coarse aggregate. The particle size grading standard of my country's graded crushed stone stipulates that the graded crushed stone standard sieve is composed of 9 square hole standard inspection sieves and a set of upper and lower covers. The diameters of the screens are: 0.063mm, 0.5mm, 1.0 mm, 2.0mm, 4.0mm, 8.0mm, 16.0mm, 31.5mm, 45.0mm.

2. Graded sand and gravel refers to sand and gravel (crushed stone), that is, fine aggregate and coarse aggregate in concrete, which are determined according to the laboratory ratio. The integration of various particle sizes A mixture of coarse and fine aggregates. The graded gravel standard inspection sieve is composed of 7 square hole inspection sieve grids. The diameters of the screens from top to bottom are: 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm, 0.075mm or 37.5mm, 31.5mm, 26.5mm, 19mm, 13.2mm, 9.5mm, 4.75mm.

| Specification standard for particle size distribution of graded crushed stone | |

| Side length of square hole sieve/mm | Screening quality probability/% |

| 0.063 | 4~9 |

| 0.5 | 5~35 |

| 1 | 9~40 |

| 2 | 16~47 |

| 4 | 22~60 |

| 8 | 35~68 |

| 16 | 55~85 |

| 31.5 | 85~89 |

| 45 | 100 |

Sieve analysis of aggregates is used in a variety of applications in the construction industry, including:

1. Concrete mix design: Sieve analysis is used to determine the particle size distribution of aggregates, which is important for designing concrete mix ratios. Particle size distribution helps determine the amount of water and grout required to produce a viable concrete mixture with desired properties such as strength, workability and durability.

2. Asphalt mixture design: Sieve analysis is used to determine the particle size distribution of aggregates used in asphalt mixtures. Particle size distribution helps determine the amount of bituminous binder needed to produce a mix with desired properties such as stability, durability and resistance to deformation.

3. Aggregate Quality Control: Sieve analysis is used to ensure that the aggregate meets the required specifications and is suitable for its intended use. The particle size distribution helps determine the gradation of the aggregate, which is important for producing high-quality building materials.

4. Soil analysis: Sieve analysis can be used to determine the particle size distribution of soil samples, which is of great significance for geotechnical applications such as foundation design, slope stability analysis, and soil compaction.

5. Research and development: Sieve analysis is used in research and development to study the behavior of aggregates under different conditions. This information is used to develop new building materials and improve existing ones.

Sieve analysis of aggregates uses screening equipment to separate and classify mixed materials under different mesh sizes. Depending on the size of the particles, the particles will pass or be blocked. Through indicators such as screening efficiency and cumulative screening curve, the distribution and particle size characteristics of particles can be evaluated. The working principle is to use the sieve hole size on the sieve to limit the size of the particles passing through, so as to achieve the classification and separation of the particles, so as to understand the particle size distribution and shape characteristics of the particles.

Sieve analysis is a technique used to determine the particle size distribution of aggregates. Aggregates are materials such as sand, gravel, and crushed stone that are used in the construction industry for various applications such as making concrete, asphalt, and roadways. The sieve analysis of aggregates involves the following steps:

1. Sample Preparation: A representative sample of the aggregate is collected and dried to remove any moisture. The sample is then weighed to determine the initial weight of the aggregate.

2. Selection of Sieves: A series of sieves with different mesh sizes is selected based on the desired particle size distribution. The sieves are stacked in descending order of mesh size, with the finest sieve at the bottom and the coarsest sieve at the top.

3. Sieving: The sample of aggregate is placed on the top sieve of the stack and the sieves are shaken for a specified amount of time to allow the particles to pass through the mesh. The amount of material retained on each sieve is weighed and recorded.

4. Calculation: The weight of material retained on each sieve is divided by the total weight of the sample to determine the percentage of material that is retained on each sieve. The percentage of material passing through each sieve is calculated by subtracting the percentage retained from 100%.

5. Plotting the Results: The results of the sieve analysis are plotted on a graph, with the percentage of material passing through each sieve on the y-axis and the sieve size on the x-axis. The resulting curve is called a particle size distribution curve, which provides information on the distribution of particle sizes in the aggregate.

| Dia. (mm) |

Height (mm) |

Frame | Bottom | Hole | Opening Size |

| 300 | 50 | Iron | Stainless Steel | Square / Round | Random |

| 300 | 50 | Stainless Steel | Stainless Steel | Square / Round | Random |

| Dia. (mm) |

Height (mm) |

Frame | Bottom | Hole | Opening Size |

| 200 | 50 | Iron | Stainless Steel | Square / Round | Random |

| Stainless Steel | Stainless Steel | Random | |||

| Brass | Brass | ≤4mm | |||

| Brass | Stainless Steel | Random |

Quality control

Sieve analysis is an important tool for quality control in the construction industry. It helps to ensure that the aggregate meets the required specifications and is suitable for its intended use. This contributes to the production of high-quality building materials that are safe and durable.

Uniformity

Sieve analysis helps ensure that aggregates are of uniform size and grade. This is important for producing consistent concrete, asphalt and other construction materials with desired properties such as strength, workability and durability.

High efficiency

Sieve analysis is a fast and efficient method for determining the size distribution of aggregates. Results are available in a short period of time, allowing rapid decision-making and reducing downtime during construction.

Cut costs

Helps reduce waste and increase efficiency for significant cost savings. By ensuring aggregates are of the proper size and grade, it reduces the need for additional handling or rework, which can be costly.

1. Weigh 500g of aggregate (superfine aggregate can be weighed as 250g), put it on the top sieve (ie 4.75mm sieve) of the set of sieves arranged in the order of sieve hole size, put a cover on it, and install the whole set of sieves on the shaker. On the sieve, shake for 10 min.

2. Remove the set of sieves, and sieve them one by one on a clean shallow tray according to the size of the sieves, until the throughput per minute does not exceed 0.1% (0.5g) of the total sample. The granules that passed were incorporated into the next sieve and hand sieved with the sample from the next sieve. Do this in sequence until all the sieves are exhausted.

3. Weigh out the sieve remainder of each sieve. The sieve remainder of the sample on each sieve shall not exceed the remaining amount. Calculate the remainder by the following formula. When it exceeds, the sieve remainder shall be divided into two parts, and then sieved. The sum of the two sieves is used as the sieve balance of the sieve.

Example of Sieve Analysis of Coarse Aggregate Test:

Individual Gradation of 20mm Aggregate (Single Size):

Wt. of Sample Taken: 9000 gm

| Sieve Size (mm) |

Retained Wt. (gm) |

Retained % (Col.IIx100/W) |

Retained % Cumulative |

% Passing (100-Col.IV) |

Limit as per IS:383 |

| I | II | III | IV | V | |

| 40 | 0 | 0 | 0 | 100 | 100 |

| 20 | 227 | 2.52 | 2.52 | 97.48 | 85-100 |

| 12.5 | – | – | – | – | – |

| 10 | 7389 | 82.10 | 84.62 | 15.38 | 0-20 |

| 4.75 | 1350 | 15.00 | 99.62 | 0.38 | 0-5 |

| Pan |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.