Multi deck vibrating screen

Multi deck vibrating screen  2 deck vibrating screen

2 deck vibrating screen  3 deck vibrating screen

3 deck vibrating screen  5 deck vibrating screen

5 deck vibrating screen  6 deck vibrating screen

6 deck vibrating screen

Provides up-to 1-7 levels of gradation for precise particle size distribution in one single operation

![]()

![]()

![]()

Price:$800.00-$4,900.00/Set

Consult now and enjoy a 10% discount

Function: Screening\separation\sorting\sieving

Layers: 1-6 layers

Mesh size: 5-200 mesh

Capacity: 100Kg-20Tons/hour

Power: (0.37-2.2)*2KW

Material: Carbon Steel/Stainless Steel 304

Cleaning system: Bouncing Ball Cleaning System

Application: Screening and grading of dry powder or granular materials in chemical, food, plastic, medicine, metallurgy, building materials, grain, fertilizer and other industries.

Commitment:

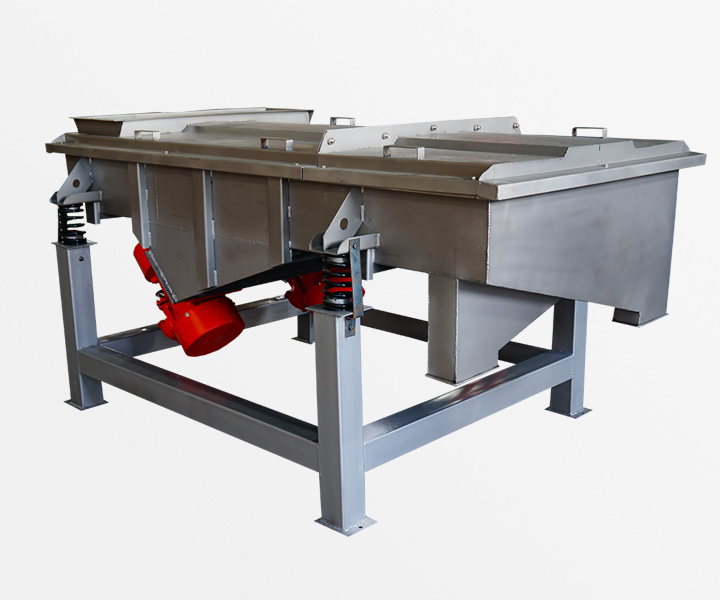

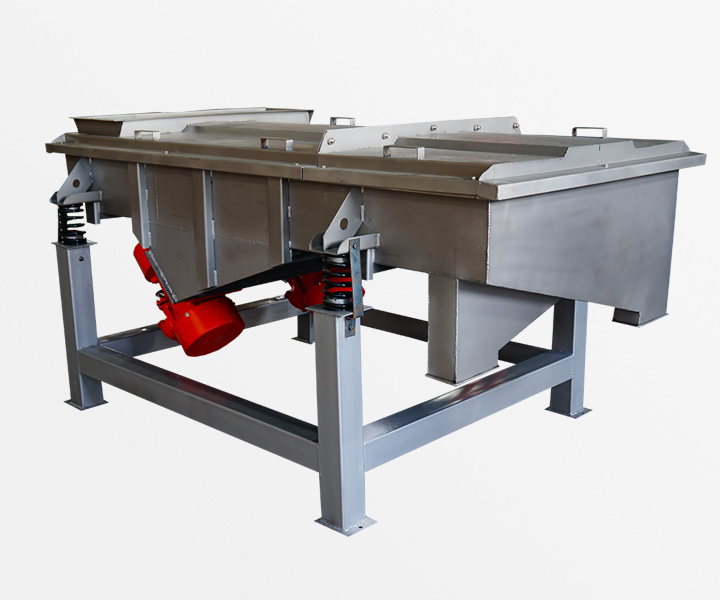

Multi deck vibrating screen is to separate the mixture into a variety of specifications with different particle sizes. Simply put, the multi deck vibrating screen has multi deck screens. According to the mesh size of the screen, the mixture is separated into finished products with different fineness. Separating up to 7 different products at a time as it builds up to 6 decks.

1-deck vibrating screen: has only 1 layer screen, but it has 2 discharge outlets. The powder with particle size larger than the screen size will be discharged from the upper outlet of the machine, while the powder with particle size smaller than the screen size will be discharged from the lower outlet of the machine.Its main function is to remove impurities.

2-deck vibrating screen: has 2 layers screen, but it has 3 discharge outlets. It can screen powder into 3 different sizes. Main functions of 2 layers linear vibrator sifter are grading and removing impurity.

3-deck vibrating screen: has 3 layers screen, but it has 4 discharge outlets.

By analogy, Dahan multi deck vibrating screen can separate up to 7 products of different specifications at the same time.

The multi deck r vibrating screen consists of multiple discharge ports, which can divide the finished material into various sizes, which can produce accurate particle classification from up to 6.

1. Grading and screening: Continuously grading and screening mixed materials of different particle sizes to become products with different particle sizes.

2. Screening impurities: high fluidity powder processing, quickly remove large particles or fine powder with little content.

1. Food industry: powdered sugar, starch, salt, rice flour, milk powder, egg powder, beans, spices, etc.

2. Chemical industry: resins, industrial drugs, cosmetics, paints, herbal powders, etc.

3. Pharmaceutical industry: industrial drugs, traditional Chinese medicine powders, granules and pills, etc.

4. Metal and metallurgical mines: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, charcoal powder, coal, electrolytic copper powder, electromagnetic material, grinding powder, refractory material, kaolin, lime, Alumina, heavy calcium carbonate, quartz sand, etc.

5. Other industries: papermaking, additives, activated carbon, etc.

Multi deck vibrating screen uses the vibration motor to excite the vibration power source, so that the material is thrown up on the screen. At the same time, it moves in a straight line. The material enters the feeding port of the vibrating screen from the feeder evenly, and passes through the multi deck screen. Various specifications of oversize and undersize are produced and discharged from their respective outlets.

Multi deck separation

It can carry out 7-level screening, 1, 2, 3, 4, 5, 6 or 7 layers, and one material can be sorted with 2-7 different particle size specifications.

High efficiency

Due to its large screening area, it provides high efficiency material when screening, the accuracy can reach more than 96%, and 20 tons/ hourly production.

Dual motor

Two vibration motors are installed on both sides of the screening equipment to ensure proper vibration for accurate screening and grading of materials.

Easy to clean screen

The Multi deck vibrating screen is equipped with a simple clamping system that allows the operator to easily clean the screen when required.

Save labor costs

It can realize a variety of specifications of materials in one feeding, saving time and effort and saving workshop expenses.

Clean and hygienic

The closed structure can eliminate the dust problem in the screening process and improve the working environment.

1. Different screening materials: Single deck vibrating screen is for the screening of one material, and multi deck vibrating screen can be used for screening of multiple materials or single materials with multiple precisions.

2. Different processing capacity: single-layer equipment will be higher than multi-layer equipment under the same model.

3. Different feeding methods: the feeding amount determines the service life and output of the equipment. Since the single deck vibrating screen only handles one kind of material, it can be appropriately increased when feeding, and since the multi deck vibrating screen handles multiple materials at the same time, it is necessary to pay attention to the feeding amount when feeding.

4. Different prices: In terms of design and production costs, the multi-layer price of the same type of vibrating screen is higher than that of single-layer equipment.

Multi deck vibrating screen for bran grading

Multi deck vibrating screen for stone powder grading

| Model | Screen size (mm) |

Layer | Mesh size (mesh) |

Capacity (t/h) |

Vibration times | Double amplitude (mm) |

Motor Power (kw) |

Vibration direction angle | Dimensions (L×W×H)mm |

| DZSF520 | 500×2000 | 1 | 92-20 | 0.05-5 | 960 | 6-7 | 2×0.37 | 45-60 | 2140×808×848 |

| 2DZSF520 | 2 | 0.05-5 | 6-7 | 2×0.37 | 45-60 | 2199×808×878 | |||

| 3DZSF520 | 3 | 0.03-5 | 4-6 | 2×0.37 | 45 | 2256×808×938 | |||

| DZSF525 | 500×2500 | 1 | 0.06-8 | 5-7 | 2×0.37 | 45-60 | 2462×808×848 | ||

| 2DZSF525 | 2 | 0.06-8 | 4-6 | 2×0.37 | 45 | 2699×808×878 | |||

| 3DZSF525 | 3 | 0.06-8 | 6-8 | 2×0.55 | 45-60 | 2750×808×938 | |||

| 4DZSF525 | 4 | 0.1-15 | 5-7 | 2×0.55 | 45 | 2813×808×1000 | |||

| 5DZSF525 | 5 | 0.08-15 | 5-7 | 2×0.55 | 45 | 2883×808×1060 | |||

| 6DZSF525 | 6 | 0.07-15 | 6-8 | 2×0.75 | 45-60 | 2953×808×1120 | |||

| DZSF1020 | 1000×2000 | 1 | 0.12-20 | 6-8 | 2×0.55 | 45-60 | 2152×1320×900 | ||

| 2DZSF1020 | 2 | 0.11-20 | 5-7 | 2×0.55 | 45-60 | 2219×1320×960 | |||

| 3DZSF1020 | 3 | 0.10-2 | 5-7 | 2×0.75 | 45-60 | 2286×1320×1030 | |||

| 4DZSF1020 | 4 | 0.07-15 | 4-8 | 2×0.75 | 45-60 | 2353×1320×1100 | |||

| 5DZSF1020 | 5 | 0.07-15 | 4-8 | 2×0.75 | 45-60 | 2420×1320×1160 | |||

| 6DZSF1020 | 6 | 0.01-15 | 4-8 | 2×0.75 | 45-60 | 2487×1320×1220 | |||

| DZSF1025 | 1000×2500 | 1 | 0.1-15 | 5-7 | 2×0.75 | 45 | 2203×1320×900 | ||

| 2DZSF1025 | 2 | 0.18-15 | 5-7 | 2×0.75 | 45 | 2269×1320×960 | |||

| 3DZSF1025 | 3 | 0.07-15 | 6-8 | 2×0.75 | 45-60 | 2336×1320×1030 | |||

| DZSF830 | 800×3000 | 1 | 0.1-20 | 6-8 | 2×0.55 | 45-60 | 3080×1098×1120 | ||

| 2DZSF830 | 2 | 0.1-20 | 6-8 | 2×0.55 | 45-60 | 3140×1098×1180 | |||

| 3DZSF830 | 3 | 0.1-20 | 6-8 | 2×0.55 | 45-60 | 3200×1098×1240 | |||

| DZSF1030 | 1000×3000 | 1 | 0.1-20 | 6-8 | 2×0.75 | 45-60 | 3152×1340×1120 | ||

| 2DZSF1030 | 2 | 0.1-20 | 6-8 | 2×1.1 | 45-60 | 3219×1340×1120 | |||

| 3DZSF1030 | 3 | 0.1-20 | 6-8 | 2×1.1 | 45-60 | 3286×1340×1120 | |||

| DZSF1224 | 1200×2400 | 1 | 0.1-23 | 6-8 | 2×1.1 | 45-60 | 2480×1520×1100 | ||

| 2DZSF1224 | 2 | 0.1-23 | 6-8 | 2×1.1 | 45-60 | 2540×1520×1160 | |||

| 3DZSF1224 | 3 | 0.1-23 | 6-8 | 2×1.5 | 45-60 | 2600×1520×1220 |

Multi deck vibrating screen is mainly composed of screen box, screen frame, screen mesh, vibration motor, motor base, vibration damping spring, bracket and so on.

In order to make it more convenient for you, you can compare the following table to clear your machine configuration

(You can also click this link to contact us directly)

| General requirements | Model | DZSF-520/525/530/1020/1025/1030 |

| Number of Layers(L) | 1-6(Suggest ≤ 3) | |

| Main Material | Stainless Steel(304/316L)•Carbon Steel(Q235)•PP | |

| Number of vibrations (times/min) |

960 | |

| Sealing Strip | Silica gel / Rubber | |

| Special requirements | Overall height of the fuselage | Please communicate specifically |

| Feed inlet | Angle / Size and so on | |

| Outlet | Angle / Size /Add valve | |

| Observation port | Silicone cover / Rubber cover / Glass cover | |

| spring | You can choose whether to add a silicone protective cover | |

| Internal spray(mm) | PTFE / ePTFE / WC / Al2O3 | |

| Equipment surface treatment | Polishing / Sandblasting | |

| Body metal material requirements | For example: require no Cu and Zn (except electrical parts) | |

| Vibration motor | Ordinary motor / Explosion-proof motor | |

| other |

We provide you with quality products and services. Multi deck vibrating screen can be customized according to industry usage scenarios, supporting equipment and material characteristics as shown in the following products:

| Screening Material | Proportion | Mesh | Capacity kg/h |

Model |

| Millet | 0.15 | 250 mesh | 600 | DZSF-515-2s |

| Quartz sand | 1.6 | 70 mesh | 30000 | DZSF-1540-3s |

| Raisin | 0.83 | 60 mesh | 6000 | DZSF-520-1s |

| Sunflower seeds | 0.04 | 80 mesh | 7100 | DZSF-525-1s |

| Plastic particles | 0.95 | 3 mm | 500 | DZSF-515-2s |

| Flour | 0.6 | 24 mesh | 1500 | DZSF-515-3S |

| Iron ore powder | 2.3 | 150 mesh | 10000 | DZSF-1020-3s |

| Slag | 4 | 5 mm | 10000 | DZSF-1020-1s |

| Sawdust | 0.2 | 80 mesh | 18000 | DZSF-1030-3S |

| Emery | 4 | 60 mesh | 300 | DZSF-515-1S |

| Wood flour | 0.4 | 120 mesh | 2000 | DZSF-1036-4s |

| Activated carbon | 0.8 | 36 mesh | 500 | DZSF-515-1s |

Dahan multi deck vibrating screen manufacturers mainly produce 2-layer, 3-layer, 4-layer, 5-layer and other types of vibrating screens, which can be used to screen various granular, powdery or slurry materials. Reduce batches of unqualified finished materials, and avoid mixing of upper and lower levels in production, and the sorting accuracy is over 95%. In addition to conventional models, our company's multi deck vibrating screen can be customized according to the needs of the industry and users.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.