Flour is a common fine material that needs to be sifted

It can be used for cakes, pastry processing, other edible product ingredients, etc.

The flour rotary vibrating screen is made of 304/316 stainless steel that is not easy to rust, and uses the silicone sealing ring and net-cleaning pinball used in the food industry.

The flour is sieved with different mesh numbers according to different uses, and the final processing capacity is also different. The following is a summary of the flour production of different mesh numbers processed by the flour rotary vibrating screen for your reference:

According to different usage scenarios, the flour rotary vibrating screen has two purposes: filtration and impurity removal and uniform grading:

| Flour state | Mesh | Treatment capacity (kg / h) |

| Dry | 20μ(0.8mm) | 2000 |

| 30μ(0.55mm)、45μ(0.18mm) | 1500 | |

| 80μ(0.18mm) | 1200 |

1. Filtration and impurity removal: Use a single-layer flour rotary vibrating sieve to filter and remove impurities such as wheat, agglomeration, and thread in the flour to meet the primary requirements of food safety;

2. Uniform grading: By increasing the number of sieve layers, the flour is sieved with different finenesses to meet the needs of different grades of flour for different purposes.

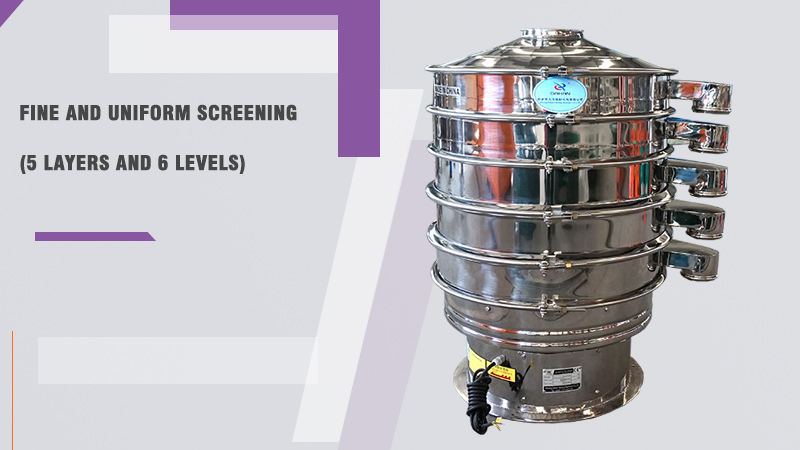

Features: fine and uniform screening (5 layers and 6 levels);

Fully enclosed to avoid flying powder;

The gate type flour rotary vibrating screen can be selected according to the needs, and the flour can be screened more uniformly;

Explosion-proof motors can be used.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.