From different perspectives, the multi-layer linear screening machine can be divided into many different types of multi-layer linear screening machines according to the material of the screening machine, the installation position of the motor, the special device and design, etc. Today we use the standard multi-layer linear screening machine to explain:

1. Product function

The multi-layer linear screening machine is a screening machine for screening a variety of materials or screening the same material at different levels. Screening of powdered or granular materials. The maximum feeding particle size is not more than 10mm.

Sieving sand

Sieving wheat bran

2. Product Capability

| Model |

Screen size (mm) |

Mesh |

Amplitude (mm) |

Power (kw) |

(length, width and height) mm |

Output (t/h) |

| DZSF520 | 500×2000 | 2-400 | 6~7 | 2×0.37 | 2140×808×848 | 0.05~5 |

| DZSF525 | 500×2500 | 5~7 | 2×0.55 | 2462×808×848 | 0.06~8 | |

| DZSF530 | 500×3000 | 5~7 | 2×0.55 | 2750×808×938 | 0.06~10 | |

| DZSF1020 | 1000×2000 | 6~8 | 2×0.55 | 2219×1320×960 | 0.1-15 | |

| DZSF1025 | 1000×2500 | 6~8 | 2×0.75 | 2269×1320×960 | 0.1-20 | |

| DZSF1030 | 1000×2500 | 6~8 | 2×1.1 | 3219×1340×1120 | 0.12-23 |

We look at its capabilities from the parameter table of the multi-layer linear screening machine:

(1) Output

Different models of multi-layer linear screening machines have different power and screen surface area, and different screening output. The output of small models (520, 525, 530) is between 0.05~10t/h, and the output of large models (1020, 1025, 1030) is between 0.1~23t/h. The larger the model, the larger the natural output, and the price will change accordingly.

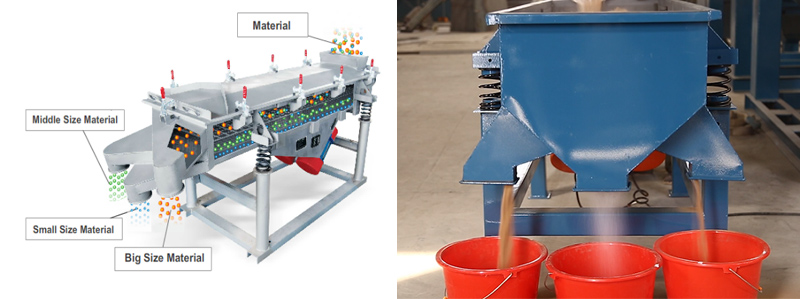

(2) Fineness

The mesh number of the material screened by the multi-layer linear screening machine is determined by the screen mesh. The mesh number of each layer of the screen mesh limits the fineness of the material, and the screen mesh of the linear screening machine is getting finer and finer from top to bottom. The mesh number of the screen is optional in the range of 2~400 mesh (0.038mm).

Of course, the inclination of the linear screening machine will also affect the screening fineness of the material. Excessive inclination will cause the material to run too fast to pass the screen and reduce the screening accuracy.

(3) Layers

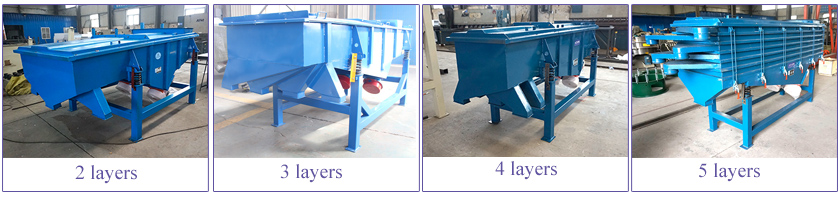

Theoretically speaking, the multi-layer linear screening machine can have 2~5 layers of screens, which can screen out 3~6 kinds of materials with different fineness.

However, in actual use, considering the screening accuracy, screening output, ease of loading and unloading of the screen, and safety in use, a 3-layer linear screening machine is generally selected for use.

If it is really necessary to use a 5-layer screen box, we can design a movable buckle box for the screen machine.

3. Product application

Multi-layer linear screening machine is mainly used for pre-screening before coarse crushing or secondary crushing, and is widely used in mining, coal, electric power, metallurgy, building materials, refractory, medicine, ceramics, grain, carbon, fertilizer, mud, plastic, abrasive, etc. Screening and grading of large materials and medium and small granular powder materials in all walks of life, it is suitable for users who have a large demand for output.

Multilayer Linear Screening Machine is a high-efficiency screening device designed for grading and separating materials into multiple particle size fractions. It uses linear vibration to move materials along the screen surface, ensuring accurate and consistent separation. With multiple screen decks, it can classify materials into several grades simultaneously, making it ideal for industries like mining, chemicals, food, and construction. Its robust design, customizable mesh sizes, and high throughput make it suitable for handling bulk materials such as granules, powders, and aggregates.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.