PET (polyethylene terephthalate) plastic is a common material used in the production of plastic bottles, packaging and other consumer goods, and sieving machines can be used to separate and grade PET plastic particles according to size, an important step in the manufacturing process.

PET (polyethylene terephthalate) plastics should be screened to ensure uniform particle size and no impurities or foreign matter. Screening is an important step in the manufacturing process of PET plastic products, especially in the production of plastic bottles and packaging materials.

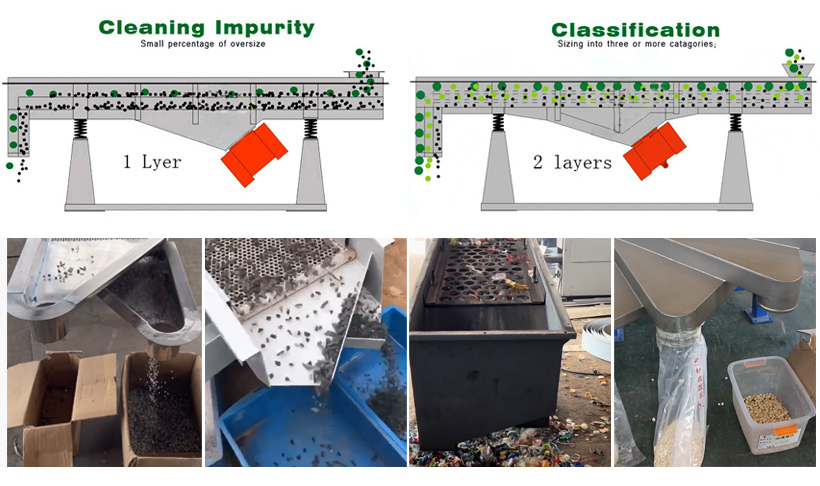

1. Grading: PET plastic sieving machine helps to separate PET plastic pellets into different size ranges, which is very important to achieve consistent product quality and performance. When the particles are uniform in size, they can be melted and shaped more easily and consistently to produce a product to required specifications.

Sieving machine for PET Plastic Bottle

Sieving machine for PET Plastic Particles

2. Removal of impurities: Screening helps remove any impurities or foreign matter that may be present in the PET plastic, such as dust, dirt or other contaminants. This is important to ensure that the final product is of high quality and free from defects or contamination that could affect its performance or appearance.

PET (polyethylene terephthalate) plastic sieving machine is designed to separate and classify PET plastic particles according to size. Some key features of PET plastic sieving machines include:

1. Premium Construction: Typically constructed of premium materials such as stainless steel or other durable metals to ensure long-lasting performance and reliability.

2. Multi-layer sieves: Usually multi-layer sieves are used, which can better separate particles according to size and provide more accurate and precise results, up to 5 different specifications or sizes for PET plastics.

3. Variable Speed Control: Many PET plastic sieving machines include adjustable speed controls, which allow for greater flexibility in the sieving process and help optimize the performance of the machine.

4. Dust collection system: A dust collection system is usually included in the sieving machine to help capture and contain any dust or particles that may be produced during the sieving process. This feature helps ensure a cleaner, safer work environment.

6. Customizable options: Usually can be customized to meet specific production requirements, including particle size, machine capacity and required level of automation.

Overall, screening is an important quality control step in the production of PET plastic products. It helps ensure that the particles are uniform in size and free from impurities, which increases the efficiency and reliability of the manufacturing process and produces high-quality products that meet specifications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.