Grading wood pellets is an important step in ensuring their quality and performance in various applications. By sorting wood pellets by size and quality, efficiency, handling and cost-effectiveness can be improved, while ensuring compliance with regulatory standards.

The mesh size selected for grading wood pellets will vary based on specific application needs and target particle size. Generally speaking, for grading wood pellets, you can choose a screen with the following mesh range:

Coarse screen level: Generally, a screen with a mesh number between 10 and 40 is selected to separate larger particles or remove impurities.

Medium sieve level: A sieve with a mesh number between 40 and 80, used to separate medium-sized particles and achieve preliminary classification.

Fine screen level: A screen with a mesh number between 80 and 120, used to separate smaller particles and achieve more detailed classification.

The specific mesh size selected depends on the desired particle size range and classification requirements. Coarse mesh sizes are suitable for separation of larger particles, while finer mesh sizes are suitable for separation of smaller particles. At the same time, the humidity, shape and production process requirements of the wood pellets must also be considered.

Sieving machines are widely used in wood pellet classification. The following are some application scenarios of sieving machines in wood pellet classification:

Primary screening: sieving machine can be used as primary screening equipment to coarsely screen raw wood particles. It can remove larger particles, impurities and large wood chips, ensuring material quality during subsequent processing.

Subdivision level: The sieving machine can also be used for subdivision level to further refine the wood particles that have been primary screened. By selecting appropriate mesh size and vibration parameters, linear vibrating screens can classify wood particles into different particle size ranges to achieve precise sorting.

Removal of fine particles: In some applications, it is necessary to remove fine particles or granular impurities from the wood pellets. The sieving machine can separate fine particles or impurities through the design of the sieve holes and control of the vibration force, thereby improving the purity and quality of the wood pellets.

The application of sieving machine in wood particle classification can improve sorting efficiency, optimize particle size and improve product quality. At the same time, it can also help realize automated grading processes, improve production efficiency and reduce manual operations.

Grading wood pellets can present several challenges, including:

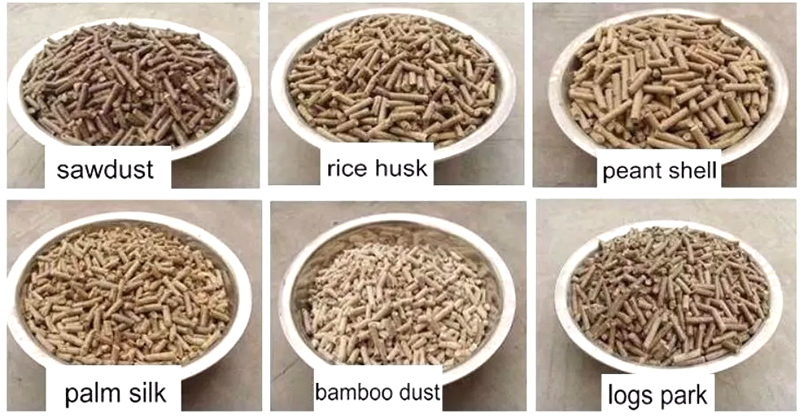

1. Variability of raw materials: The quality of wood pellets can be affected by the variability of the raw materials used in its production. Different types of wood and the presence of bark or other impurities can affect particle hardness, density and size, making consistent grading difficult.

2. Pellet breakage: Wood pellets are brittle and prone to breakage during handling and processing. This can result in fine and undersized particles, which can affect the accuracy of the grading process.

3. Moisture content: Moisture content can affect the size and density of wood pellets, making it difficult to achieve consistent grading. Too much moisture will cause the pellets to swell and become soft, while low moisture content will cause the pellets to become hard and brittle.

4. Dust: Dust generated during the grading process is a challenge as it affects the accuracy of grading and poses a safety hazard to workers.

5. Equipment limitations: The equipment used to classify wood pellets also presents challenges. For example, the mesh size of the sieve used for grading affects the accuracy of the grading, while the capacity of the equipment affects the throughput and efficiency of the grading process.

Overall, grading wood pellets can be challenging due to the variability of the raw materials used in production, as well as the potential for breakage, moisture content, dust, and equipment limitations. However, with proper selection of equipment and operating procedures, these challenges can be overcome to achieve consistent and accurate wood pellet sizing.

1. Increased efficiency: quickly and efficiently process large volumes of particles, reducing the time and labor required for manual sieving.

2. Consistent results: Designed to provide consistent and accurate results, ensuring that particles are properly separated and classified according to size and quality, and 7 different sizes or specifications of wood pellets can be separated in one operation.

3. Quality control: Wood pellet sieving machine helps to ensure that the pellets are free of impurities and foreign matter, improving the quality and safety of their use in various applications. Can help break up any lumps or clumps that may have formed during production, storage or transport, making pellets easier to handle and reducing the risk of clogging or clogging.

4. Cost-Effective: A cost-effective investment for businesses that require large quantities of wood pellets on a regular basis, as they reduce the time and labor required for manual sieving, increasing the efficiency of the production process.

When grading wood pellets, the application of a suitable sieving machine in wood pellets is a sieving machine that can efficiently and effectively separate the particles according to the desired size distribution, and the sieving machine should be equipped with a suitable sieve for wood pellets. A mesh size of 4-6 mm is generally recommended for wood particle sizing, but the exact mesh size will depend on the desired size distribution. Overall, wood pellet screeners can provide several benefits to businesses that require a consistent, high-quality wood pellet product. They can increase efficiency, consistency and quality control while reducing labor costs and improving handling.

https://www.dahanmachine.com/product-center/SIEVING-MACHINE.html

Address:China,Yanjin county forest park gate to the west 1000 meters north road.