A sieving machine for grains is a device used to separate and classify grains according to their size and consistency. Grain sifters are commonly used in the agriculture and food industries to process and pack grains such as wheat, rice, corn and barley.

Screening machines are commonly used in a variety of applications in the grain industry, including:

1. Cleaning and grading: used for cleaning and grading wheat, rice, corn and other grains. By removing impurities and separating grain by size, it helps ensure that the final product is of consistent quality and meets specific standards and specifications.

2. Sorting and Separation: Used to sort and separate grain into categories of different sizes for further processing or packaging. This helps ensure a uniform size and consistency in the final product, which is important for quality control and customer satisfaction.

3. Packing: Used to pack grains such as rice and wheat, divide them into categories of different sizes, and distribute them into bags or containers. This helps ensure that the final product is of consistent quality and meets specific packaging requirements.

4. Quality Control: Used for quality control to ensure that the grain meets specific size and consistency standards. This helps ensure that the final product is of consistent quality and meets customer expectations.

Corn Seed Sieving Machine

Linear Vibrating Screen for Peanut Grading

Several types of grain sieving machines are used in the grain industry. The most common types include:

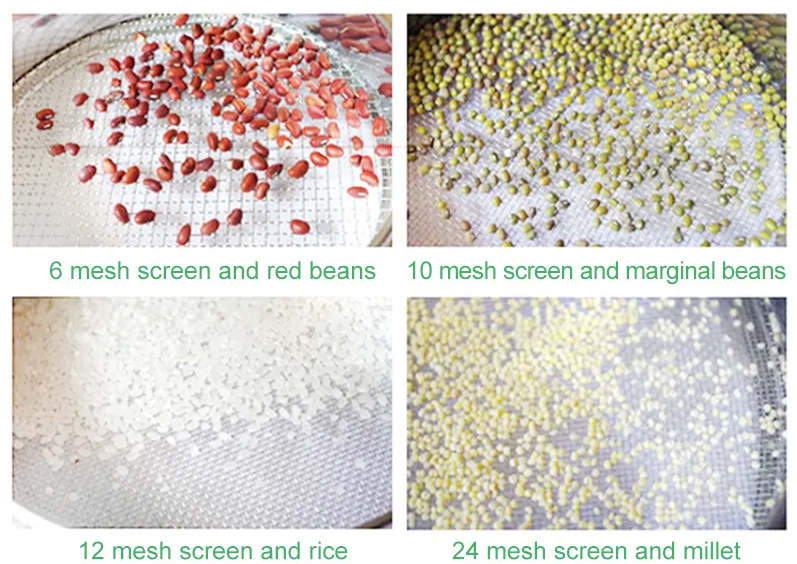

1. Linear vibrating screen: Linear vibrating screen is used for cleaning and grading of grains such as wheat, rice, corn, etc. By removing impurities and separating particles according to size, the grains are sorted into categories of different sizes for further processing or packaging, up to simultaneous Grading 7 different sizes of products, this helps to ensure that the final product has a uniform size and consistency, which is very important for quality control and customer satisfaction, more suitable for large capacity screening, there are larger screen sizes, there are Good for screening larger volumes of grain

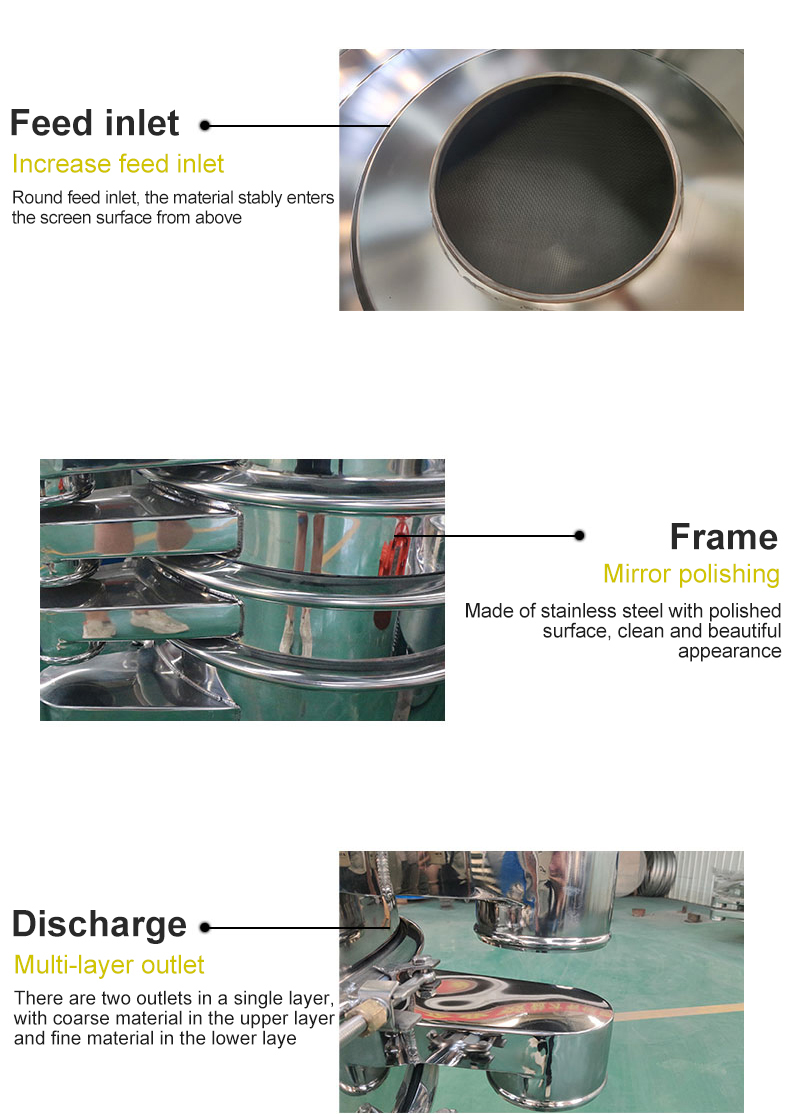

2. Rotary vibrating screen: It can be used to detect and remove foreign objects in grains, such as stones and metal fragments, which helps to prevent damage to processing equipment and ensure the safety and quality of final products, and can also sort and separate grains into different sizes It can achieve up to 5 levels of separation, and is more suitable for small-capacity screening applications. It has a smaller screen size, so the grains screened are generally fine materials.

Overall, sifters are an important tool in the grain industry to ensure grain quality and consistency. By separating and classifying grain according to size and consistency, sieving machines help ensure that the final product meets specific standards and specifications.

| Grain Name | Proportion | Mesh Size |

Capacity kg/h |

| Millet | 0.15 | 250 mesh | 600 |

| Soy | 0.73-0.88 | 70 mesh | 30000 |

| Corn | 0.75 | 60 mesh | 6000 |

| Sunflower Seeds | 0.04 | 80 mesh | 7100 |

| Sesame | 0.6 | 24 mesh | 1500 |

| Sorghum | 1.2 | 50 mesh | 2000 |

| Buckwheat | 1.33 | 60 mesh | 3200 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.