Plastic granule linear vibrating screen is used to screen plastic granules in the plastic recycling process, which can remove any impurities and powder mixed with the granules to ensure uniform granules, and can also sort plastic granules into different specifications according to particle size requirements.

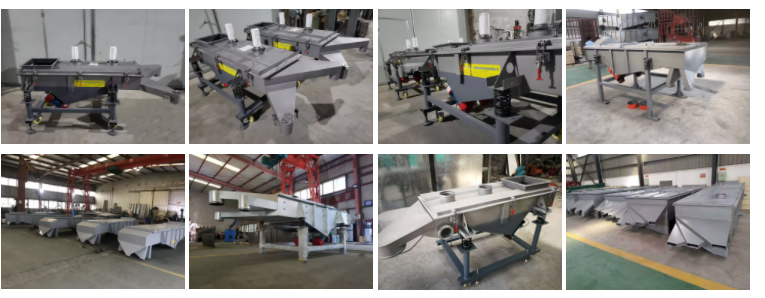

Linear Vibrating Screen For Plastic Particles is designed for efficient screening of plastic particles. It uses linear motion to separate plastic particles based on size. Widely used for quality control and material sorting in the plastics industry, this vibrating screen ensures precise particle separation and classification. With high screening efficiency and customizable features such as screen size and amplitude adjustment, the linear vibrating screen is an essential tool for achieving uniform particle size distribution and improving the quality of plastic materials.

The plastic particles enter the multi-layer linear screen equipment through the conveyor belt. Due to the dual action of the motor excitation force and its own gravity, the plastic particles jump in a straight line along the linear screen surface, and the upper plastic particles are screened out at the upper discharge port, which is smaller than the screen mesh. Several plastic particles enter the lower screen and still follow the same material movement trajectory. After passing through the three-layer screen, the plastic particles are divided into four types of materials: larger than 2.5mm plastic particles, 2.5mm-1.4mm plastic particles, 1.4mm-80 mesh plastic particles, and less than 80 mesh plastic particles, which can also be selected according to requirements. 6 layers of screens with different mesh numbers to achieve the required grading effect.

| Features | Linear vibration screen for plastic particles | Three-dimensional vibration screen for plastic particles |

| Motion trajectory | Plastic particles move linearly on the screen surfaceLinear motion | Plastic particles move three-dimensionally on the screen surface (horizontally, vertically, and tilted) |

| Screening efficiency | Relatively low | High |

| Applicable materials | Applicable to materials with large particle size, regular shape, and low precision requirements | Applicable to plastic particles with small processing volume, high precision requirements, small particle size, and irregular shape |

| Screen structure | Usually single layer or a few layers | Can be stacked in multiple layers |

| Screening accuracy | General | High |

| Processing capacity | Low | High |

| Equipment structure | Simple structure | Complex structure |

| Maintenance cost | Low | High |

| Energy consumption | Low | High |

| Applicable scenarios | Ordinary screening needs, such as preliminary screening of recycled plastics | High-precision and high-efficiency screening needs, such as fine grading of plastic raw materials |

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

The plastic pellet linear vibrating screen has a wide range of uses. Its core function is to efficiently and continuously classify, remove impurities and screen plastic pellets of different sizes. With its linear vibration trajectory and configurable multi-layer screen, the device can accurately separate various plastic raw materials, recycled materials or finished materials according to particle size, usually covering from 2 mesh of coarse screen to 100 mesh of fine screen or even higher. Coarse screen (2-10 mesh) is used to remove large pieces of material, impurities or incompletely plasticized lumps produced in processes such as injection molding and extrusion. Medium screen (10-40 mesh) is often used to classify plastic pellets of different specifications. Fine screen (40-100 mesh or more) can be used to remove plastic powder, fine impurities or classify fine particles in some special processes. Plastic pellet linear vibrating screen is used to improve product quality, optimize production processes and achieve efficient material separation with its ability to adapt to a variety of mesh sizes and handle various dry, non-sticky plastic pellets.

Linear vibrating screen for plastic particles is a multi-layer linear vibrating screen used for screening and grading powdery and granular materials. It is widely used in plastics, abrasives, chemicals, medicine, building materials, food, carbon, fertilizer and other industries. As a new type of efficient screening equipment, it can screen plastics, rubber, sand and gravel into products of different particle sizes.

1. By adding a multi-layer screen, the large particles and fine powder in the plastic particles are removed to improve the fineness of the material and distinguish different particle sizes.

2. Double motor drive to ensure proper vibration, which is 3-6 times the output of ordinary screen machines, and the output can reach 20 tons/hour.

3. A distributor can be added in the feeding section to ensure that the screen meshes are evenly distributed on the screen surface, and at the same time play the role of buffering and protecting the screen surface.

4. The upper cover of the equipment is designed with a dust removal device, which can be easily connected to the on-site dust removal equipment. In a large-scale production line, multiple screening equipment can be configured.

The linear vibrating screen for plastic particles is a stable, reliable, low-noise, long-life, high-screening efficiency device suitable for screening all dry materials with a moisture content of more than 0.74 mm and less than 10 mm, a moisture content of less than 7%, and no sticky substances. It is worth noting that the device can also be used to operate larger particles of coal powder for screening by thickening the screen body, increasing the motor power and drilling holes on the screen plate; in addition, it can also be used to screen liquids, especially for sewage treatment.

The plastic particle linear vibrating screen is suitable for the particle size of 2-400 mesh, and the required screening capacity is 0.12-20/h. It uses 6 layers to separate different particle sizes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.