Suitable for cleaning and classifying powders or granules in industries with corrosive substances such as acids, alkalis and salts

![]()

![]()

Price:$700.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Material: Polypropylene, polyvinyl chloride (PVC) or other plastic materials

Mesh Size: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Application: It is an important tool for efficient screening of corrosive materials in the chemical, pharmaceutical and food industries, ensuring that the final product is of consistent size and quality.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

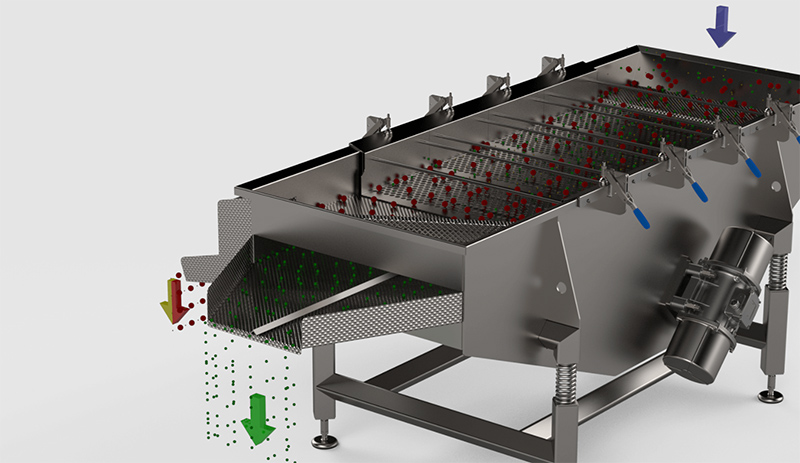

Plastic linear vibrating screen is made of polypropylene material, also called PP material, and is made by special processing technology to meet the screening operation of materials with acid, alkali and corrosiveness. The main purpose of use is to remove corrosive powder or Granules are sieved and classified.

Plastic linear vibrating screen is specially designed to solve the problems of oxidation and corrosion after contacting with Q235 ordinary carbon steel and SUS304 stainless steel. Therefore, it is widely used in the chemical industry.

Some common applications for plastic corrosion resistant linear vibrating screens include:

1. Separation of chemicals: used for separation according to the particle size and other physical properties of chemicals and other materials. This ensures a consistent quality of the final product.

2. Drug screening: used to screen drugs and other medical products to ensure that they are free of pollutants and consistent in size and quality.

3. Food processing: It is used in the food industry to screen foods such as spices, grains and other ingredients to ensure that they are consistent in size and quality.

4. Chemical processing: used in chemical processing plants to separate and grade chemical substances according to their physical properties to ensure consistent quality of final products.

Overall, the plastic linear vibrating screen is an important tool for efficient and safe screening of corrosive materials in the chemical, pharmaceutical, and food industries, ensuring that the final product size and quality are consistent, and hygienic standards are maintained.

Preservative

Made of corrosion-resistant high-quality materials such as polypropylene, polyvinyl chloride (PVC) or other plastic materials.

7 levels of separation

1-6 layers of screens with different meshes can be installed, impurities and coarse materials are automatically discharged, and products can be divided into 7 grades in one operation.

High screening efficiency

The linear motion ensures high screening efficiency, which can separate materials into different grades according to their particle size and other physical properties.

Low noise and vibration

Low noise and vibration levels are guaranteed, which are very important for the comfort and safety of the operator and the surrounding environment.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.