Screw conveyor for glass powder is a kind of equipment specially used for conveying glass powder, which is widely used in glass manufacturing, ceramics, refractory materials, powder processing and other industries. Glass powder usually refers to the powdery material formed by crushing glass raw materials (such as quartz sand, soda ash, limestone, etc.). Due to the characteristics of fine particles, easy dust and poor fluidity of glass powder, special attention should be paid to the sealing, wear resistance and conveying efficiency of the screw conveyor when designing and selecting.

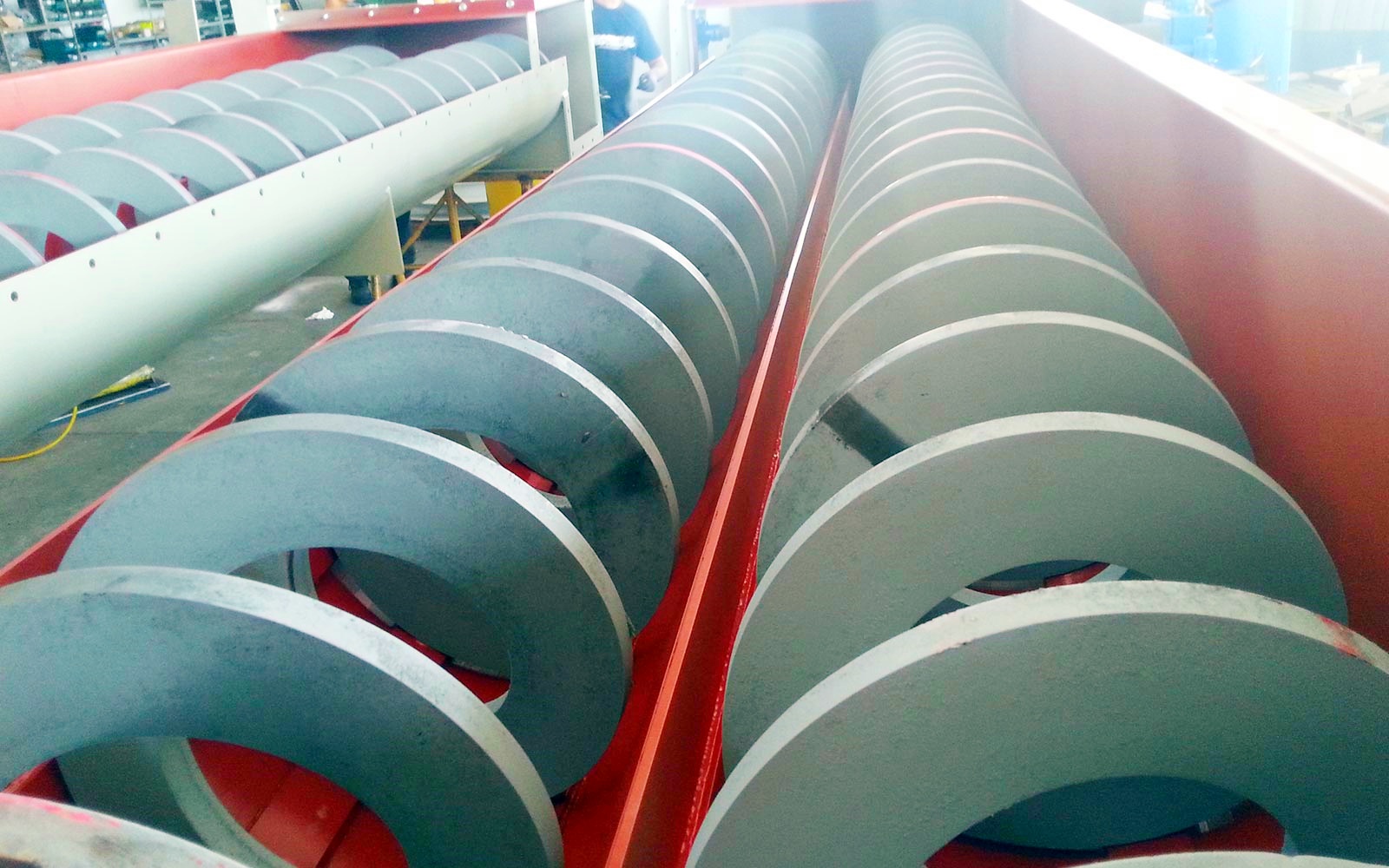

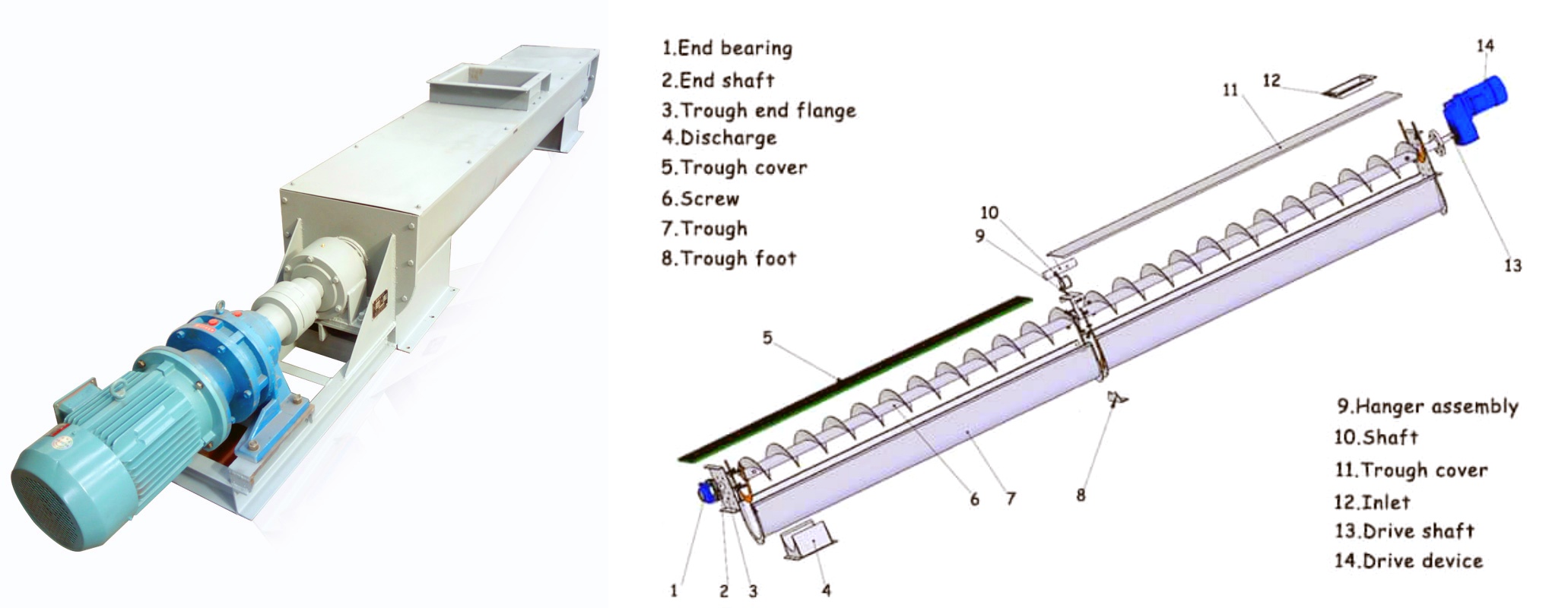

①Rotation of spiral blades: The spiral blades in the machine are driven by a motor and rotate continuously.

②Material push: The rotating spiral blades contact the glass powder, generating friction and pushing the material forward.

③Material conveying: The glass powder moves forward along the conveyor channel under the push of the spiral blades until it reaches the discharge port.

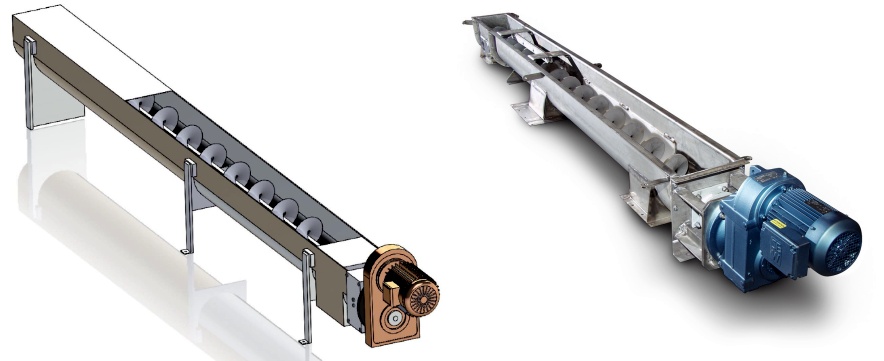

一、Tubular screw conveyor (sealed dustproof type)

① Suitable for ultra-fine glass powder transportation, fully enclosed structure to prevent dust diffusion.

② Suitable for short distance and medium conveying volume (generally <20m, 5-50 tons/hour).

③ Can be used with dust removal equipment to keep the workshop clean.

二、Shaftless screw conveyor (anti-blocking type)

① Suitable for glass powder with poor fluidity, reducing material adhesion and blockage.

②Suitable for medium conveying distance (<30m) and large conveying volume (10-100 tons/hour).

③ Suitable for high-humidity glass powder, glass slag, broken glass and other mixed materials.

三、U-shaped screw conveyor (easy maintenance type)

① Suitable for short-distance conveying (<10m), easy to disassemble and clean.

② Suitable for glass powder batching and conveying, such as feeding of feeders and mixers.

③ The open structure can be equipped with a dust cover to prevent dust diffusion.

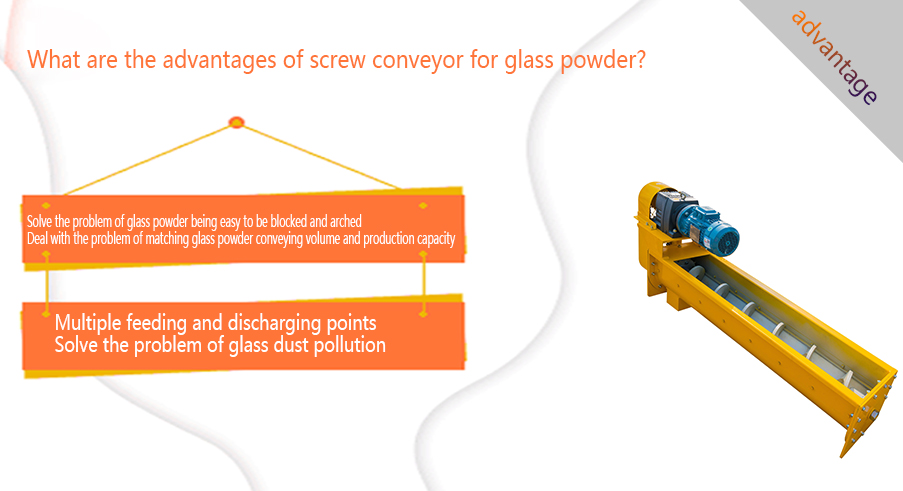

1. Solve the problem of glass powder being easy to be blocked and arched: Glass powder has high density and its fluidity is not as good as granular material. It is easy to accumulate, arch or adhere to the pipe wall in the conveying pipeline. Screw conveyor for glass powder adopts variable pitch screw in the feeding section to prevent material accumulation.

2. Deal with the problem of matching glass powder conveying volume and production capacity: Screw conveyor for glass powder can choose variable frequency motor and adjust the conveying speed according to production needs. The density of glass powder is about 1.5~2.5t/m³. The appropriate pipe diameter and power need to be selected according to process requirements.

3. Multiple feeding and discharging points: Screw conveyor for glass powder can realize multiple feeding and discharging points during the conveying process, which is convenient for the flow and distribution of glass powder between different processes and meets the diversified needs of glass production process.

4. Solve the problem of glass dust pollution: Glass powder is an ultra-fine powder, which is easy to generate dust pollution during the conveying process. Screw conveyor for glass powder is equipped with a buffer device at the feeding port to reduce the flying dust during feeding.

Technical specifications of screw conveyor for glass powder

|

Parameters |

Recommended range |

Description |

|

Pipe diameter |

50mm-200mm |

Affects the conveying capacity, common specifications are 75mm, 100mm, 150mm, etc. |

|

Conveying capacity |

1-15 tons/hour |

Need to choose the appropriate conveying capacity according to the output of glass powder |

|

Conveying angle |

0°-90° (bendable) |

Adapt to different process layouts |

|

Conveying distance |

1-30 meters |

Can be customized to different lengths |

|

Drive power |

0.75kW-5.5kW |

Affects energy consumption, matching conveying capacity |

|

Cleaning method |

Quick disassembly/reverse cleaning |

Ensure equipment hygiene and prevent residual pollution |

1. Glass raw material conveying: In the glass production process, glass powder needs to be conveyed from the storage bin to the production line. Screw conveyor for glass powder can continuously and stably convey the powder to the specified location.

2. Glass melting furnace feeding: The glass melting furnace needs to add glass powder and other raw materials into the melting furnace for melting. Screw conveyor for glass powder can accurately convey the powder to the charging port of the melting furnace to ensure the normal operation of the melting furnace.

3. Glass product production: The production process of glass products requires the glass powder to be conveyed to the molding equipment for molding. Screw conveyor for glass powder can continuously and evenly convey the powder.

4. Glass powder recycling: The glass production process will produce some waste materials, which can be reused after processing. Screw conveyor for glass powder can convey these waste materials to the recycling and processing equipment to realize the reuse of resources.

Screw conveyor for glass powder is a reliable conveying equipment, which is particularly suitable for short-distance transportation of powdery and granular materials such as glass powder.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.