Potato plate chain conveyor is a device used to convey potatoes or similar granular materials. It is usually used in potato production lines or processing lines in the food processing industry. This conveyor uses a plate chain as a conveying medium, which can transport potatoes or potato products from one location to another, realizing automated conveying and processing.

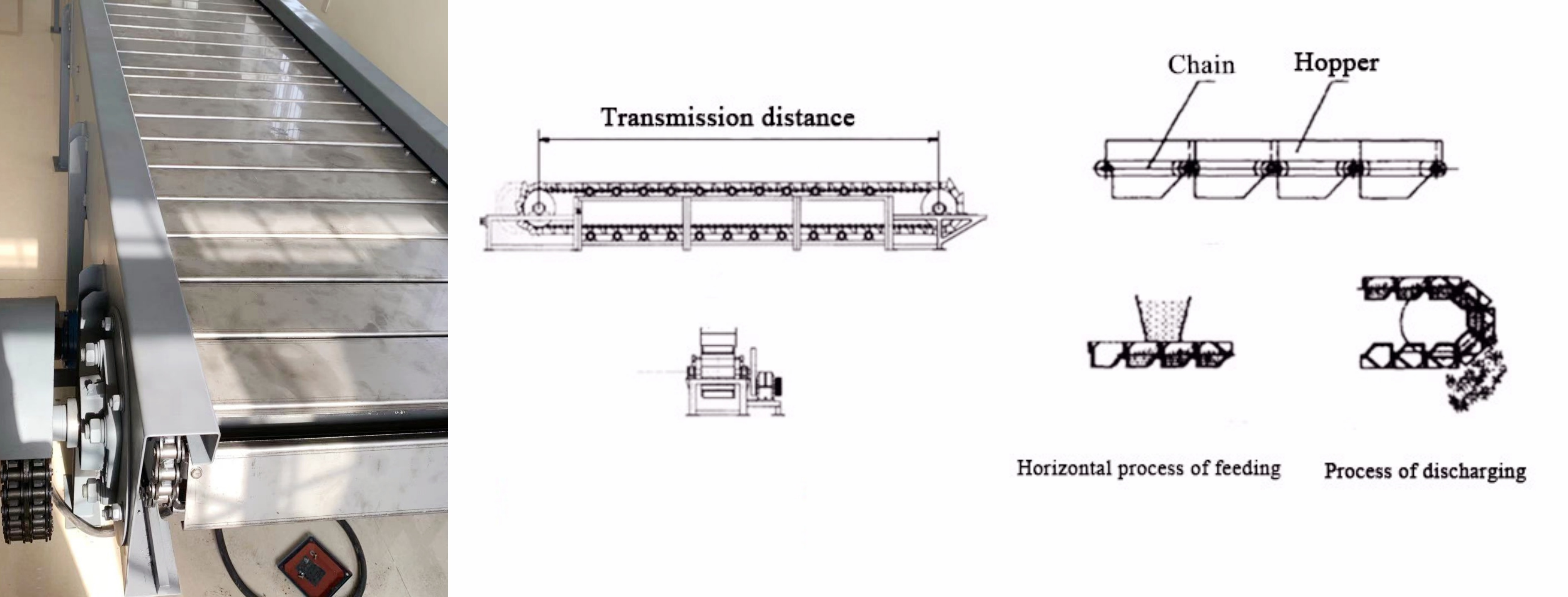

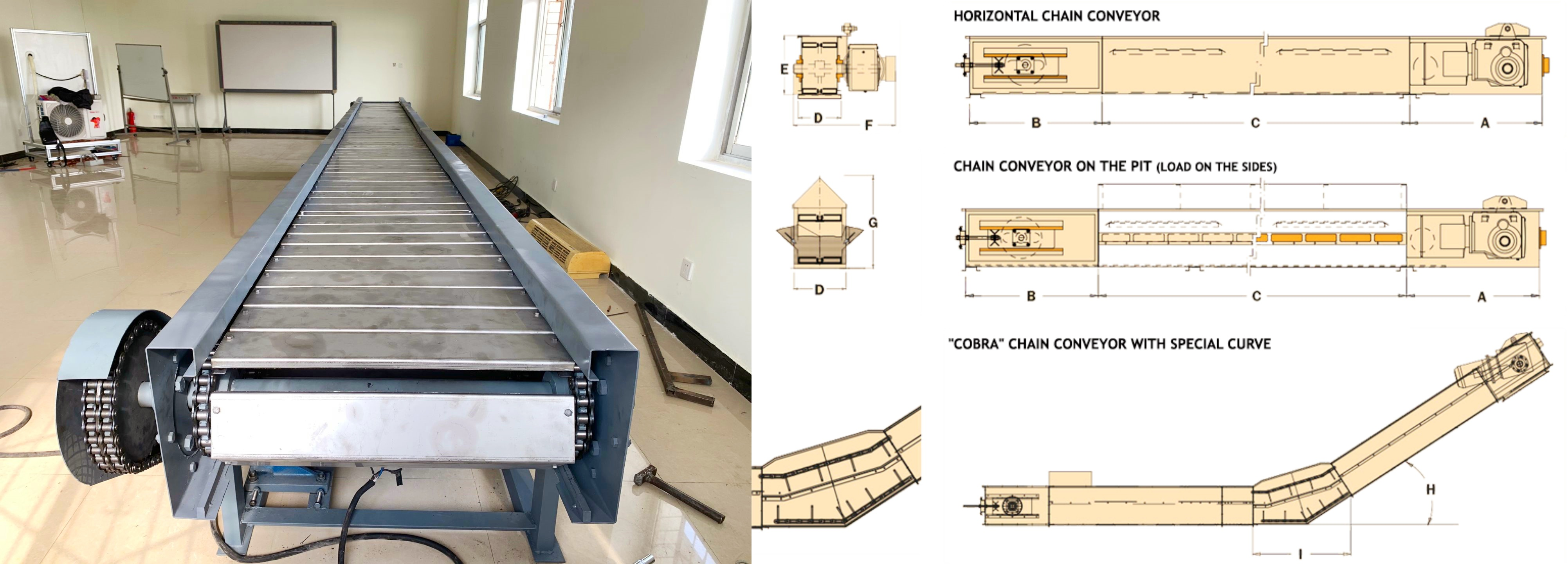

①Potato plate chain conveyor is mainly composed of a drive device, a chain, slats, a frame and a support device.

②The drive device drives the chain to run, and the slats on the chain carry the potatoes to move.

③By adjusting the speed of the drive device and the running direction of the chain, continuous and stable transportation of potatoes can be achieved.

Potato plate chain conveyor achieves efficient, stable and hygienic potato transportation through a sturdy frame, durable chain plates, a stable drive system, flexible inlet and outlet ports, and an optional cleaning and protection system.

✅ Reduce potato damage and improve the yield rate

✅ Adapt to different processing environments (cleaning, frying, freezing, etc.)

✅ Support automatic cleaning and meet food grade standards

✅ Customizable multiple conveying methods to adapt to different process flows

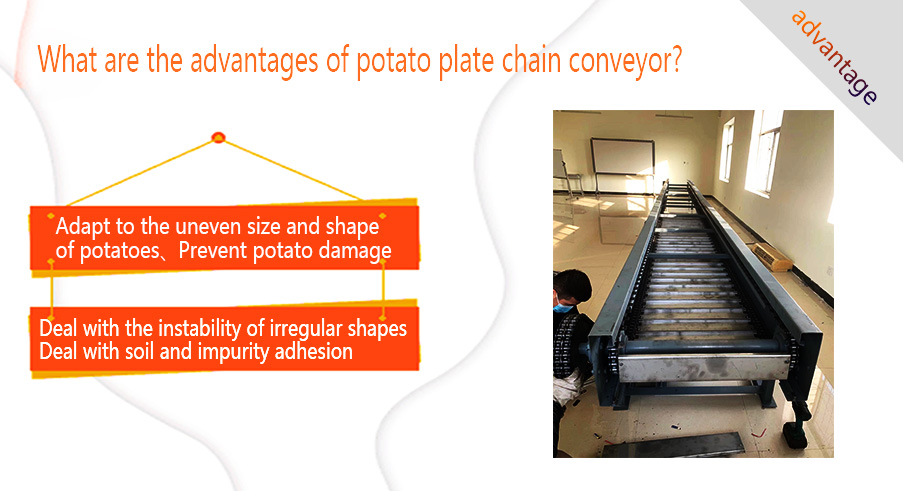

1. Adapt to the uneven size and shape of potatoes: potato plate chain conveyors are generally equipped with wider chain plates, with common widths of 600mm, 800mm, etc., which can adapt to potatoes of different sizes. Potato plate chain conveyors can be stably placed and conveyed on the chain plates.

2. Prevent potato damage: Potato plate chain conveyor runs smoothly, the chain plate moves at a uniform speed, and has small jitter and low noise during operation, which can avoid collisions between potatoes and collisions between potatoes and equipment parts due to equipment vibration or sudden changes in speed.

3. Deal with the instability of irregular shapes: the plate width and the height of the sidewall can be customized (such as 500mm wide and 50mm high) to adapt to potatoes of different sizes and prevent rolling. The running speed of the plate chain conveyor is adjustable (such as 3-10 meters/minute), and the sorting efficiency is increased by 20%.

4. Deal with soil and impurity adhesion: Potato plate chain conveyor uses wear-resistant materials to make chains and plate surfaces to resist the wear of soil and gravel. The board surface is designed to be hollow or with small holes, allowing small impurities (such as sand) to fall naturally and reduce accumulation.

|

Project |

Parameters/Specifications |

Project |

Parameters/Specifications |

|

Equipment model |

TB-500, TB-800, TB-1200, etc. |

Conveying capacity |

5-50 tons/hour |

|

Conveying length |

2-50 meters |

Conveying width |

400-1200 mm |

|

Conveying height |

Customizable |

Chain material |

Stainless steel (304/316), carbon steel (surface treatment) |

|

Chain type |

Flat top chain, chain with side guard |

Drive mode |

Motor drive |

|

Motor power |

1.5-15kW |

Conveying speed |

0.1-1.0 m/s |

|

Maximum inclination |

0°-30° |

Applicable ambient temperature |

-20°C to 120°C |

|

Protection level |

IP54 or higher |

Cleaning method |

Removable, easy to clean |

|

Power requirement |

380V/50Hz Or customized |

control system |

PLC automatic control |

|

Equipment weight |

according to customization |

noise level |

≤75dB |

|

Optional functions |

dust removal device, drainage design, anti-skid chain plate |

||

1. Potato processing production line: between potato washing, peeling, slicing, frying and other processing links, it is used to transport potato raw materials and intermediate products to achieve continuous connection of various processing steps, such as transporting potatoes from the storage area to the washing machine, or transporting washed potatoes to the peeling machine, etc.

2. Potato storage logistics: in the potato warehouse, it can be used to transport potatoes from the unloading point to the storage area, or transport potatoes from the storage area to the loading point when shipping. It can also be used for the transfer of potatoes between different warehouse areas to facilitate the handling and storage management of potatoes.

3. Potato grading and screening: used with potato grading and screening equipment, the potatoes of different grades that have been screened are transported to the corresponding collection area or packaging line respectively, realizing the automatic grading and transportation of potatoes.

Small workshop (daily processing ≤5 tons): choose a width of 400mm, equipped with a 1.1kW motor, and an investment of about 20,000-30,000 yuan.

Medium-sized factories (daily processing 20-50 tons): use double-row 800mm wide chain plates, equipped with 4kW motors and automatic lubrication systems.

Large production lines (daily processing ≥100 tons): customize three-row 1200mm ultra-wide chain plates, integrated metal detection and automatic rejection modules.

Potato plate chain conveyors play an important role in potato processing and production lines. They can achieve efficient transportation and processing of potatoes, improve production efficiency, reduce labor costs, and ensure the smooth progress of potato processing.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.