Industrial powder screw conveyor is a kind of mechanical equipment widely used in powder material conveying, which is widely used in chemical, food, pharmaceutical, building materials and other industries. It is particularly suitable for processing fine, dry or fluid powder in industrial production, such as cement, flour, chemical raw materials, mineral powder, sawdust powder, etc. It pushes the powder material forward along the conveying trough or pipeline through the rotating spiral blades, realizes the horizontal, inclined or vertical conveying of materials, and realizes efficient and continuous conveying.

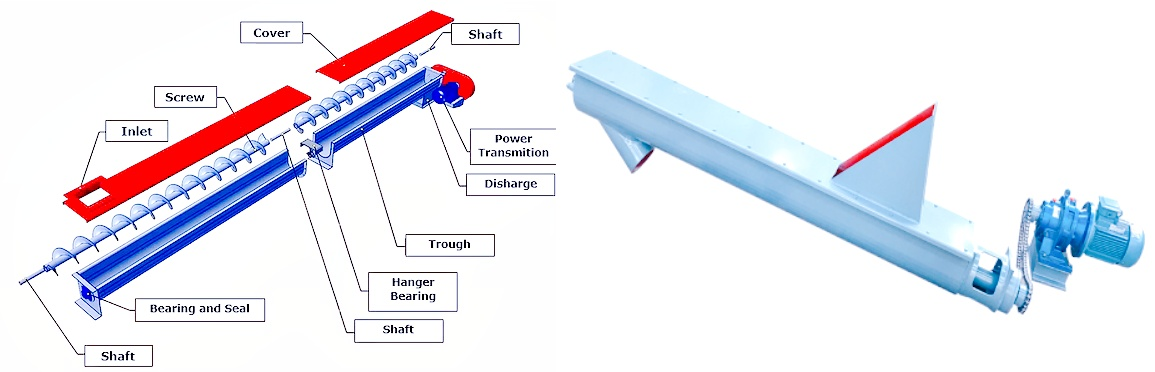

①Industrial powder enters the conveying trough or tube through the feed port.

②The motor drives the spiral to rotate, and the blades push the industrial powder along the axial direction.

③The industrial powder moves forward by friction and spiral thrust, and is finally discharged from the discharge port.

④Depending on the installation angle (horizontal, inclined or vertical), the conveying direction and efficiency will change.

I. Classification by structural form

(1) Tubular screw conveyor

Structure: A closed pipeline is used, and the spiral blades rotate in the pipeline to convey materials.

Scope of application: Suitable for conveying powders with good fluidity, such as cement powder, lime powder, flour, etc., suitable for continuous operation.

(2)U-shaped screw conveyor

Structure: It is in the shape of a U-shaped groove, with the spiral blades placed in the U-shaped groove and equipped with a removable cover.

Scope of application: Suitable for short-distance transportation, such as food, medicine, chemical industry and other industries, suitable for conveying powders that are prone to clogging or adhesion.

2.Classification by conveying method

|

Type |

Horizontal screw conveyor |

Inclined screw conveyor |

Vertical screw conveyor |

|

Picture |

|

|

|

|

Features |

Mainly used for horizontal conveying, the conveying distance is generally not more than 30m |

Applicable to inclined conveying (0°~45°), the larger the conveying angle, the lower the conveying capacity |

Applicable to vertical conveying (90°), the lifting height can reach more than 10m |

|

Applicable scenarios |

Applicable to cement, fly ash, lime powder, food powder, etc. |

Applicable to conveying that requires a certain lifting height, such as feed, chemical powder, etc. |

Applicable to occasions where the plant space is limited but the material needs to be lifted vertically, such as food, metallurgy, pharmaceutical industry, etc. |

|

Advantages |

High conveying efficiency and relatively simple structure |

Material conveying can be achieved in a limited space, but reflux problems are prone to occur |

Feeding device is required to prevent material reflux |

3.Classification by screw shaft structure

Shafted screw conveyor: The spiral blades are fixed on the central shaft, suitable for finer powders, such as cement, mineral powder, flour, etc.

Shaftless screw conveyor: no central shaft, suitable for materials with high viscosity and humidity, such as sludge, sticky powder, etc.

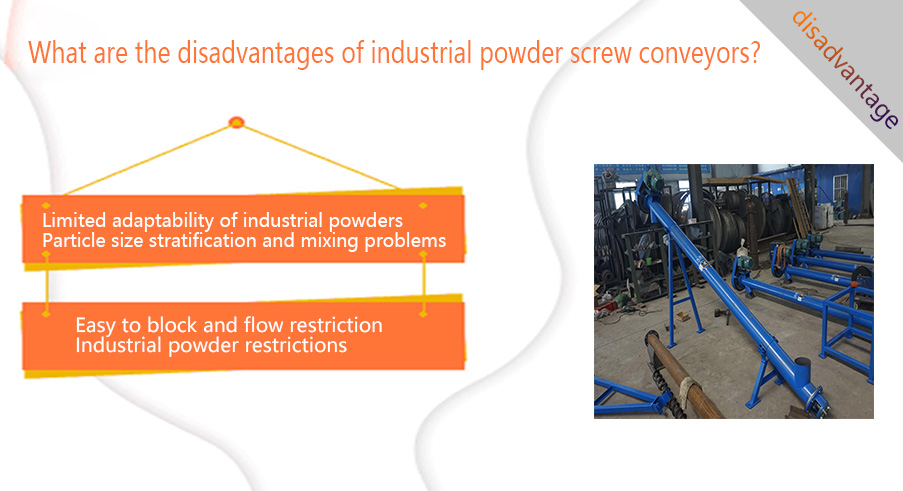

1. Limited adaptability of industrial powders: not suitable for conveying powder materials with high viscosity, easy to agglomerate, high humidity or uneven particle size distribution. Industrial powder materials with uneven particle size distribution may be stratified during the conveying process, affecting the conveying effect.

2. Particle size stratification and mixing problems: Industrial powder particles of different densities or particle sizes may be stratified, and variable diameter spirals or stirring blades are required to assist in mixing. During long-distance transportation, fine powder may lag behind coarse particles, resulting in uneven unloading.

3. Easy to block and flow restriction: Viscous or wet powders are easy to adhere to the blades or pipe walls, but may still be blocked. Ultrafine powders are easy to agglomerate, and coarse particles may be blocked, requiring precise control of the blade gap and speed.

4. Industrial powder restrictions: Viscous industrial powders are easy to adhere to the spiral blades and the walls of the conveying trough, causing blockages, and abrasive industrial powder materials will accelerate the wear of the spiral blades and the conveying trough.

Chemical industry: Various powdered raw materials (such as pigments, dyes, catalysts, additives, etc.) need to be transported from the storage area to the reactor or mixing equipment. Industrial powder screw conveyors can achieve accurate and stable transportation of these powders.

Building materials industry: In cement plants and dry mortar production lines, industrial powder screw conveyors are used to transport raw materials such as gypsum powder, stone powder, cement, fly ash, limestone powder, etc.

Food industry: In flour mills and starch mills, industrial powder screw conveyors are used to transport raw materials such as flour and starch, and flour can also be transported to dough mixers.

Industrial powder screw conveyors are suitable for a variety of industrial fields and can meet the transportation needs of different materials, improving production efficiency and work efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.