Perforated plate standard screen is a screen made of metal perforated plate, mainly used for the detection of large-particle materials and materials that have impact on the screen. Its mesh types include round holes and square holes, and the mesh size ranges from 0.2 mm to several hundred millimeters. The material of the perforated plate standard screen is usually stainless steel, which is resistant to acid, alkali and salt corrosion, and can withstand high temperatures below 300°C. The screen and the screen frame are fixed by welding to ensure that they will not loosen, and are suitable for particle size screening and testing in laboratories, inspection departments and other places.

Specific application areas include the detection of large-particle materials such as soil, asphalt, coal, sand and gravel, aggregates, etc. In addition, the perforated plate standard screen is also commonly used in various laboratories, item screening, grading and other inspection departments, and is suitable for the screening of cement clinker, chemicals, coffee, building materials, fertilizers, fillers, flour, grain, metal powder, minerals, nuts, plastics, sand, seeds and other materials.

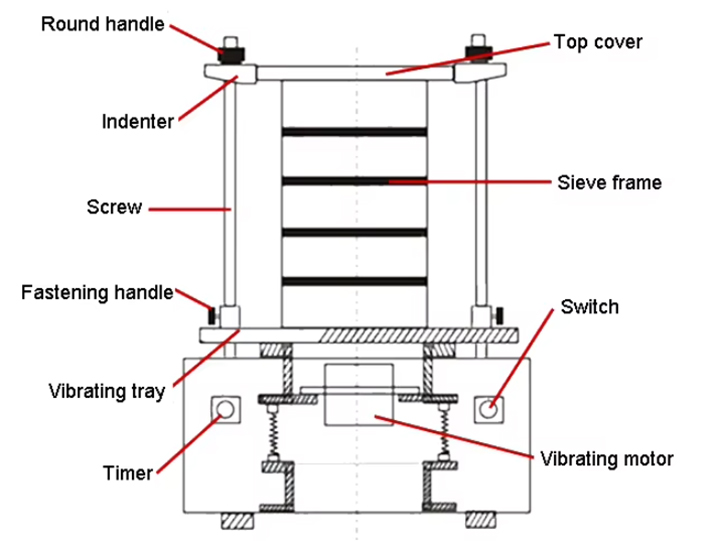

Vibration motor: Provides excitation force to make the screen surface vibrate and realize material screening.

Base: Supports the entire equipment to ensure the stable operation of the equipment.

Screen frame: Consists of a base and a screen, the screen is installed on the screen frame to screen the material.

Screen: Usually made of metal materials, with wear resistance, high temperature resistance and other characteristics.

Perforated plate: The surface is punched to form a certain size of aperture, which is used to screen materials of different particle sizes.

The perforated plate standard screen vibrates the screen surface through the excitation force generated by the vibration motor, and the material gradually moves forward under the action of gravity and vibration force. Larger materials are blocked above the screen, and smaller materials fall into the lower layer through the screen holes, thereby realizing material screening. Its working process includes the steps of exciting force transmission of the vibration motor, material movement, screening and discharging.

The perforated plate standard screen uses the exciting force generated by the vibration motor to make the screen surface vibrate, and the material gradually moves forward under the action of gravity and vibration force, thereby achieving efficient screening.

The aperture of the perforated plate standard screen can be customized according to user needs to ensure high screening accuracy, and is suitable for occasions with high screening accuracy requirements.

Corrosion resistance and high temperature resistance: The perforated plate standard screen is made of stainless steel and other materials, with good corrosion resistance and high temperature resistance, suitable for harsh environments.

Mining: used for screening and grading of mineral materials such as coal, ore, and limestone.

Building materials: suitable for screening and grading of building materials such as cement, sandstone, and concrete.

Chemical industry: used for screening and grading of chemical raw materials such as fertilizers, plastic particles, and pigments.

Food processing: suitable for screening and grading of food raw materials such as grains, flour, and powdered sugar.

Pharmaceuticals: used for screening and grading of pharmaceutical raw materials such as powders and herbal granules

As an important screening equipment, the perforated plate standard screen plays a key role in the screening and grading of granular materials. Its efficient screening ability, stable operating performance and wide range of applications make it one of the indispensable equipment in many industries. Through reasonable selection and use, the perforated plate standard screen can improve production efficiency, optimize product quality, and meet the needs of different industries for granular material screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.