Industrial waste screw conveyor is a kind of equipment used to convey various forms of industrial waste, such as powder, granules, waste, etc. It adopts a spiral structure and transports waste from one place to another by spiral rotation. It is commonly used in waste treatment plants, environmental protection industries, mining and metallurgical industries, etc. Industrial waste screw conveyor has the characteristics of continuous conveying, flexible layout, and easy maintenance.

1.Fine powder materials: For fine powder waste, such as cement dust, coal powder, etc., choose a tubular or U-shaped screw conveyor with good sealing to reduce dust flying.

2.Granular materials: For granular waste, such as plastic particles, metal chips, etc., choose a shaft or shaftless screw conveyor, and choose the appropriate spiral blade and conveying trough size according to the size and shape of the particles

3. Block or entangled materials: For block or entangled waste, such as construction waste, sludge, etc., choose a shaftless screw conveyor. The shaftless design can effectively prevent material entanglement and blockage.

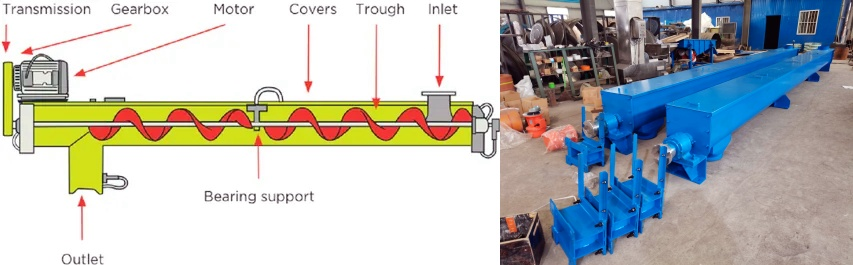

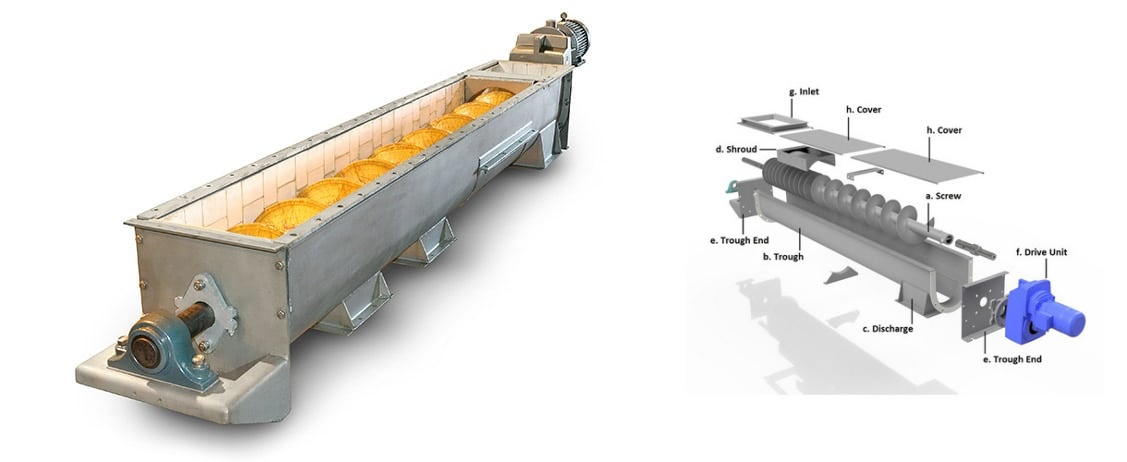

When the drive device drives the screw shaft to rotate, the industrial waste loaded into the trough cannot rotate with the screw due to its mass and the internal friction between the particles and the external friction between the trough wall, but can only move forward along the machine trough under the axial driving force of the screw, and the industrial waste is discharged when it reaches the discharge port.

1. Solve the problem of complex characteristics of industrial waste: There are many types of industrial waste. Industrial waste screw conveyors can adjust the screw diameter, pitch and speed according to the material characteristics to meet the transportation needs of different wastes.

2. Handle different forms of waste: Industrial waste screw conveyors can adapt to various forms of waste, whether it is powder, granules or other forms of waste, they can be effectively transported, making waste treatment more convenient.

3. Reduce the blockage and jam of industrial waste: Through the design of the spiral structure, the industrial waste screw conveyor can effectively avoid the accumulation and blockage of waste during the transportation process and keep the transportation smooth.

4. Reduce the adhesion and residue of industrial waste: Viscous waste is easy to adhere to the spiral or tank body, and even cause secondary pollution. The industrial waste screw conveyor removes the central axis, reduces the adhesion points, and is suitable for high-viscosity waste.

|

Material type |

Particle size range (mm) |

Recommended screw diameter (mm) |

Recommended pitch (mm) |

Recommended speed (rpm) |

Application scenario |

|

Metal chips |

0.1-5 |

200-400 |

150-300 |

30-60 |

Metal processing plants, waste recycling |

|

Wood chips/sawdust |

0.5-10 |

200-400 |

150-300 |

30-60 |

Wood processing plants, biomass fuel production |

|

Plastic chips |

2-20 |

300-500 |

200-400 |

20-50 |

Plastic recycling plants, recycled plastic production |

|

Construction waste |

10-100 |

400-600 |

300-500 |

15-40 |

Construction sites, waste cleaning |

|

Ore Waste |

5-50 |

400-600 |

300-500 |

15-40 |

Mines, tailings treatment |

|

Chemical waste |

0.1-2 |

200-400 |

150-300 |

30-60 |

Chemical plants, waste treatment |

|

Dust waste |

0.01-0.5 |

150-300 |

100-200 |

40-80 |

Chemical plants, dust recovery |

|

Large waste |

50-200 |

600-800 |

500-700 |

10-30 |

Construction sites, mines |

1. Industrial production workshop: In the industrial production process of chemical, metallurgical, building materials, etc., it is used to transport the waste generated in the production process, such as waste slag, waste powder, etc., from various production links to the waste collection point or treatment equipment.

2. Waste treatment plant: It can be used to transport various industrial wastes in the process of urban waste treatment, such as sorted waste plastics, metal fragments, construction waste, etc. The shaftless screw conveyor can also be used to transport sludge generated in the process of waste treatment to avoid sludge entanglement and clogging of equipment.

3. Resource recycling site: In the waste recycling plant, the recycled industrial waste, such as waste paper, plastic bottles, metals, etc., are transported to the corresponding processing equipment or storage area for classified recycling and reprocessing.

|

Problem |

Cause analysis |

Solution |

|

Low conveying efficiency |

Spiral blade wear or too low speed |

Replace spiral blades or adjust speed. |

|

Material blockage |

Material humidity is too high or viscosity is too high |

Clean up the blocked material, adjust material characteristics or equipment parameters. |

|

Excessive equipment vibration |

Unstable support frame or unbalanced drive device |

Check and adjust the support frame and drive device. |

|

Dust leakage |

Damage or unreasonable design of sealing device |

Replace sealing device or improve design. |

Industrial waste screw conveyors play an important role in waste treatment and material transportation, improving production efficiency, reducing labor costs, and meeting environmental protection requirements. Through reasonable selection and regular maintenance, the equipment can be ensured to operate stably for a long time, meet the needs of industrial waste treatment, and reduce operating costs and improve production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.