Clean coal powder cyclone screen is a device used for coal powder processing, which mainly screens and grades coal powder by airflow rotation. This equipment plays a key role in coal processing and pulverized coal plants, helping to improve the quality of coal products and reduce energy waste. It is also beneficial to environmental protection. The clean coal powder cyclone screen is usually used in the screening, grading and cleaning processes of coal powder to meet the production needs of coal products with different particle size requirements.

1. Airflow classification: After the clean coal powder is fed into the cyclone screen, it is affected by high-speed rotating airflow. The finer coal powder rises with the airflow, and the coarser coal powder is thrown to the outer wall under the action of centrifugal force and then settles.

2. Centrifugal separation: By adjusting the air flow speed and centrifugal force, the grading particle size of the coal powder can be controlled. Coal powders of different particle sizes are separated into different areas and then collected.

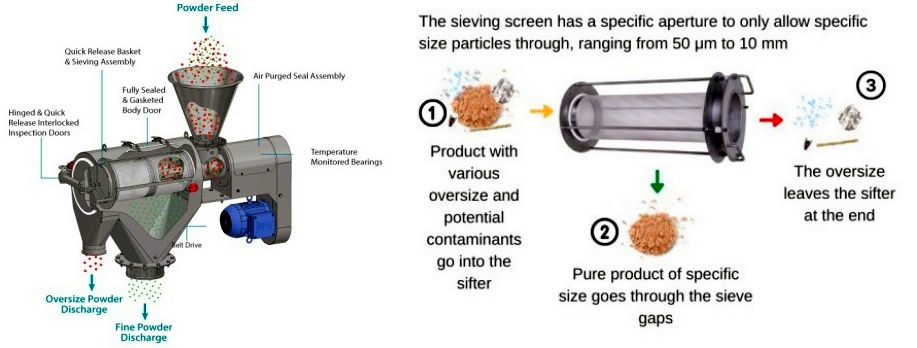

Accurate screening: Through screens with different mesh sizes, clean coal powder that meets specific particle size requirements passes through the screen, while coarse particles and impurities are intercepted on the screen.

Efficient impurity removal: It can effectively remove various impurities in clean coal powder, such as gangue debris, pyrite particles, sawdust, etc.

Prevent agglomeration: Use rotating blades and other devices to break up the clean coal powder entering the screen body, effectively preventing the clean coal powder particles from agglomerating into blocks.

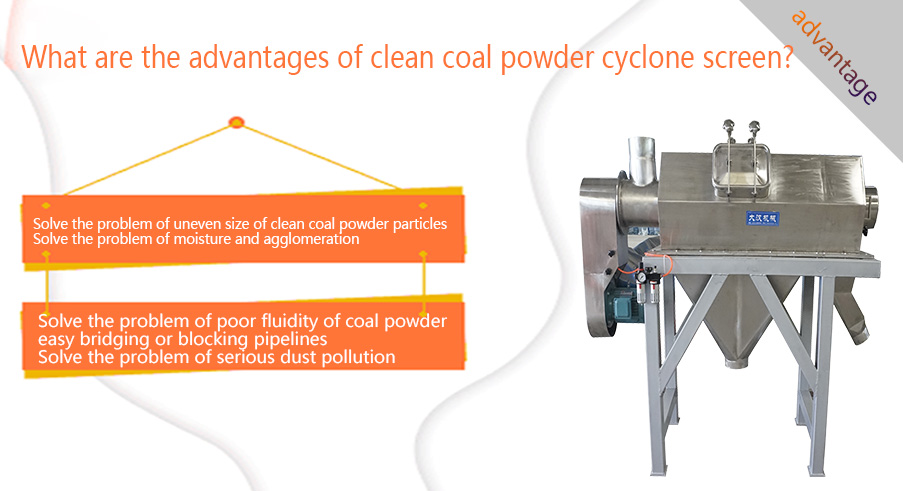

1. Solve the problem of uneven size of clean coal powder particles: The clean coal powder cyclone screen is equipped with screens of different meshes (such as 100 mesh, 200 mesh, 325 mesh) to classify the clean coal powder into coarse, medium and fine particle sizes. The horizontal, vertical and tilting movements of the rotary vibrating screen make the coal powder evenly distributed on the screen surface, avoid local accumulation, and improve the classification accuracy.

2. Solve the problem of moisture and agglomeration: Some clean coal powder cyclone screens can integrate hot air systems to dry trace moisture while screening, prevent coal powder from agglomerating, improve coal powder fluidity, and ensure smooth transportation.

3. Solve the problem of poor fluidity of coal powder, easy bridging or blocking pipelines: Clean coal powder particles are small and have poor fluidity. It is easy to form a "bridge" phenomenon in the conveying pipeline or silo, affecting continuous production. Use anti-blocking hoppers and spiral feeding systems to ensure that coal powder enters the screen evenly to avoid one-time accumulation.

4. Solve the problem of serious dust pollution: Clean coal powder particles are small and easily suspended in the air, causing serious dust pollution in the workshop. The clean coal powder cyclone screen adopts a fully enclosed structure to prevent dust leakage and ensure a clean and safe working environment.

|

Purpose |

Recommended mesh number |

Aperture (mm) |

Description |

|

Coarse screen (removing large particles) |

60 mesh-100 mesh |

0.25-0.15 |

Remove unground residue, suitable for primary classification |

|

Medium fine screen |

120 mesh-200 mesh |

0.125-0.074 |

Standard clean coal powder, suitable for boiler combustion |

|

Ultrafine screening |

250 mesh-400 mesh |

0.061-0.037 |

High purity requirements, such as coal powder for metallurgy or chemical industry |

1. Preparation of coal powder in coal-fired power plants

After the coarse coal powder is output from the coal mill, it enters the cyclone screen through the conveying pipeline, and the clean coal powder with a particle size of 120 mesh-200 mesh is screened and transported to the combustion furnace. The clean coal powder cyclone screen passes through multiple layers of screens to ensure uniform coal powder particle size and improve combustion efficiency.

2. Production of pulverized coal for injection in the metallurgical industry

The ground pulverized coal enters the fine coal cyclone screen, and after screening out the ultra-fine fine coal powder, it is directly transported to the blast furnace spray gun through a closed pipeline. The fine coal cyclone screen is equipped with a high-mesh screen (such as 325 mesh or 400 mesh) to accurately separate the pulverized coal that meets the injection requirements.

3. Purification of fine coal in chemical raw materials

After crushing and grinding, the coarse coal powder is sent to the cyclone screen to screen out the fine coal powder of 200-325 mesh and transport it to the subsequent reactor or granulation equipment. The 60-100 mesh screen removes the unground large particles, and the screen above 200 mesh purifies the pulverized coal.

4. Coal powder recovery and environmental protection treatment

The waste gas enters the cyclone screen through the pipeline, and the recyclable fine coal powder (100 mesh-200 mesh) is separated, and the remaining gas is discharged through the dust collector. The cyclone separator uses centrifugal force to capture the suspended coal powder, and the vibrating screen further classifies the usable part.

5. Refined production of small coal powder processing workshops

A small amount of coarse coal powder is manually fed into a small cyclone screen (such as a 600mm diameter model), and clean coal powder of about 150 mesh is screened out and bagged or used directly. The clean coal powder cyclone screen can replace the screen (100 mesh-200 mesh) to meet the needs of different particle sizes.

Clean coal powder cyclone screen can effectively solve the dust, blockage, classification and safety problems in transportation by combining vibration screening and cyclone separation technology. If you need more specific equipment model or parameter recommendations, you can contact our customer service or send an email, and we will provide you with detailed information and quotes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.