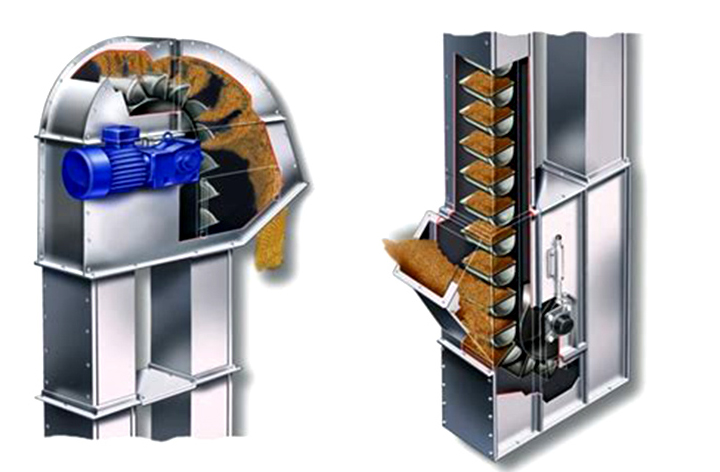

Continuous bucket elevator for powder bulk materials is a continuous conveying machine that uses a series of hoppers fixed on the traction parts to convey powder, granular and block materials in a vertical direction or at a large angle. It mainly conveys powder bulk materials to the silo or packaging machine. The continuous bucket elevator for powder bulk materials is mainly composed of the casing, traction parts (belts or chains), hoppers, drive wheels, redirecting wheels, tensioning devices, drive devices and other components. The working principle of the bucket elevator is that at the bottom of the bucket elevator, the hopper on the traction part scoops up the material, and as the traction part gradually lifts the material to the top of the bucket elevator, the hopper turns downward after bypassing the top wheel, and pours the material into the receiving trough. The empty hopper continues to move downward to the bottom to enter the next cycle, and the material is sent out of the bucket elevator through the receiving trough.

The continuous bucket elevator for powder bulk materials is suitable for conveying non-abrasive and low-abrasive materials in powder, granular and small blocks, such as coal powder, cement powder, gravel powder, sand powder, clay powder, ore powder, etc. Since the traction mechanism of the elevator is a circular chain, it is allowed to convey materials with higher temperatures, and the material temperature does not exceed 250°C. The general conveying height can reach up to 40 meters, and the TG type can reach up to 80 meters.

There are three types of continuous bucket elevators for powder bulk materials, including ring chain, plate chain and belt, each type has its specific application scenarios and advantages. For example, the ring chain has a simple structure and a firm connection with the hopper, which is suitable for conveying highly abrasive materials; the plate chain has a firm structure and a light weight, which is suitable for elevators with large lifting capacity; while the belt has a simple structure, but is not suitable for conveying highly abrasive materials. Bucket elevators are widely used and are mainly suitable for continuous vertical lifting of powdery, granular and small-piece materials. They can be widely used in the lifting of bulk materials in feed mills, flour mills, rice mills, oil mills, starch mills, grain depots, port terminals, etc. of various sizes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.