The wood chip bucket elevator is a machine used to transport wood chips and other materials. It consists of a bucket, a lifting belt and a transmission device. The bucket is installed on the lifting belt, and the transmission device drives the lifting belt, thereby driving the bucket to lift the material.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

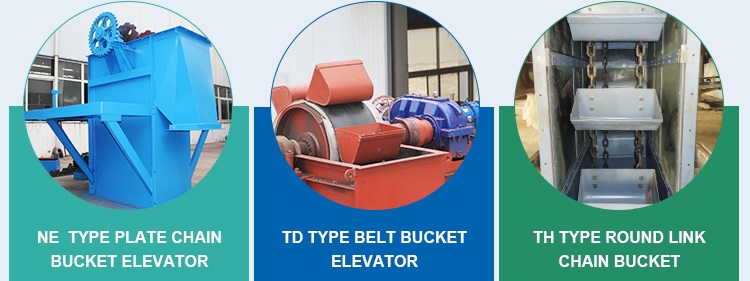

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: It is used in biomass power plants, wood pellet plants, sawmills and other industries to transport wood chips, wood chips and other materials.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Bucket elevator for wood chips is a specific type of bucket elevator designed and optimized for handling wood chips. It is commonly used in industries such as forestry, wood processing, biomass energy, pulp and paper. Bucket elevators efficiently lift and transport wood chips vertically for easy transfer and movement within the facility.

When it comes to handling wood chips, a bucket elevator can be an efficient and reliable solution for transporting them to different levels or locations within a facility. The buckets are designed to scoop up the wood chips from a hopper or a receiving point at the bottom and carry them upward. As the buckets move along the conveyor, they can discharge the wood chips at the desired height or at specific discharge points.

Bucket elevators for wood chips are used in a variety of applications within industries involving wood chip handling and processing. Here are some common applications:

1. Wood chips storage: The bucket elevator can transport the wood chips from the receiving area to the storage bin or box. They provide a convenient and efficient method of vertical transfer, allowing chips to be stored in elevated positions and optimizing space utilization.

2. Biomass power plant: used to transport wood chips from the storage area to the combustion unit, ensuring a stable and controlled fuel supply.

3. Wood pellet production: Wood chips can be transported between different stages of the pelletizing process such as drying, grinding and pellet formation.

4. Wood chip processing: Wood chips can be transported to equipment such as chippers, shredders or hammer mills for further size reduction, or to other processing units such as dryers or screening systems.

5. Pulp and Paper Industry: Typically used to transport wood chips within a facility, such as moving them from chip bins to digesters or from storage areas to pulp mills.

1. Efficient vertical transportation: specially designed for vertical lifting and transportation of materials. They provide an efficient method of moving wood chips between different floors or locations within a facility, minimizing the need for manual labor and reducing handling time.

2. Increased throughput and productivity: By automating the process of lifting and transferring wood chips, bucket elevators can significantly increase the overall throughput and productivity of wood chip handling operations. They can process large volumes of wood chips at a continuous and controlled speed, resulting in a smooth and efficient workflow.

3. Space optimization: By lifting wood chips vertically, they make efficient use of vertical space, especially where storage or processing areas are limited. This can free up valuable floor space for other equipment or processes.

4. Reduce material degradation: wood chips can be treated gently, minimizing the risk of material degradation and maintaining the quality of wood chips. Buckets are designed to scoop up and carry chips without undue impact or damage.

5. Dust control: It can be equipped with dust control measures, such as dust removal system or closed conveyor, to minimize dust emission and maintain a clean and safe working environment.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

When selecting bucket materials for handling wood chips in a bucket elevator, it's important to consider the characteristics of the wood chips, such as their abrasiveness and moisture content. Here are some commonly used bucket materials for handling wood chips:

High-Density Polyethylene (HDPE): HDPE is a popular choice for bucket construction due to its excellent abrasion resistance, impact strength, and low friction properties. It is commonly used for handling wood chips with moderate to high abrasiveness. HDPE buckets are lightweight and offer good resistance to moisture, chemicals, and wear.

Nylon: Nylon buckets are known for their exceptional strength and durability. They have high resistance to abrasion, impact, and moisture, making them suitable for handling wood chips with higher abrasiveness. Nylon buckets are also relatively lightweight and have good resistance to various chemicals.

Urethane: Urethane buckets are preferred for their outstanding abrasion resistance, flexibility, and toughness. They can withstand highly abrasive wood chips and offer excellent impact resistance. Urethane buckets are also resistant to moisture, chemicals, and oils, making them suitable for demanding wood chip handling applications.

Stainless Steel: Stainless steel buckets are used when wood chips have extremely high abrasiveness or when there are concerns about contamination. Stainless steel is highly resistant to wear, corrosion, and chemical damage. These buckets are durable, easy to clean, and suitable for handling wood chips in harsh environments.

Reinforced Plastic or Composite Materials: Reinforced plastic or composite buckets combine the benefits of different materials, such as fiberglass or carbon fiber, with a polymer matrix. These buckets offer enhanced strength, rigidity, and impact resistance, making them suitable for handling wood chips with high abrasiveness or in heavy-duty applications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.