It is usually used to vertically lift powder materials to different heights to meet the transportation needs during the production process.

![]()

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: Widely used in food processing, chemical, pharmaceutical and metallurgical industries for efficient and reliable vertical transportation of powder and fine-grained materials, such as flour, cement, fly ash, coal powder, lime powder, etc.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

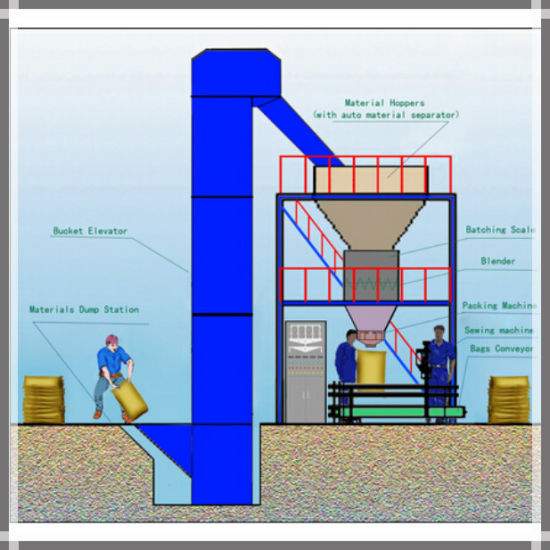

Powder bucket elevator is a bucket elevator specially used to handle powder or fine-grained materials. It is usually used to vertically lift powder materials to positions of different heights to meet the transportation needs during the production process.

Powder bucket elevators are designed to solve the special challenges when handling powder materials, such as minimizing dust generation, preventing material breakage and ensuring accurate and efficient conveying. In order to maintain the integrity of the material during transportation, powder bucket elevators are usually equipped with features such as dust-proof systems, anti-static measures, and gentle handling mechanisms.

Powder bucket elevators are widely used in various industries, including but not limited to the following fields:

Food processing: Powder bucket elevators are often used in the food processing industry for vertical transportation of powder, flour, powdered sugar, starch, cereals and other materials. They can transport raw materials from the ground to different process equipment such as mixers, dryers, packaging machines, etc.

Chemical industry: Powder bucket elevators in the chemical industry are used to transport various chemical powders and granular materials, such as plastic particles, fertilizers, pigments, rubber powder, etc. They can transport feedstock from the ground or storage tanks to reactors, drying equipment, screens, etc.

Metallurgical industry: In the metallurgical industry, powder bucket elevators are used to transport metal powder, ore powder and other materials. They can transport raw materials from the ground or storage tanks to smelting furnaces, sintering machines, grinding mills, etc.

Other industries: Powder bucket elevators are also used in plastic processing, building materials, environmental protection and other industries to transport corresponding powder or fine-grained materials.

Efficient vertical conveying

The powder bucket elevator can vertically lift powder materials to different heights to achieve multi-layer or high-rise transportation. It can effectively utilize space and meet the vertical transportation needs in the process flow.

continue to operate

The design of the powder bucket elevator enables continuous operation, increasing production efficiency and reducing production downtime. It can continuously lift materials from below to above, achieving uninterrupted material transportation.

Flexible to adapt to differences

Suitable for handling various powder materials, including fine powder, granular materials, etc. It can be customized and designed according to different material characteristics to ensure stable conveying and fluidity of materials.

Height adjustable and flexible layout

The height of the powder bucket elevator can be adjusted according to actual needs to adapt to different working scenes and layout requirements. It can be flexibly installed and arranged according to site conditions to meet the factory's space constraints and process needs.

Dust control and environmentally friendly

It has good sealing performance and dust-proof control measures, which can reduce dust leakage and environmental pollution. This is particularly important for industries that require clean production environments and prevent dust explosions.

Reliability and ease of maintenance

Hoist usually adopts solid structure and reliable transmission system, which has high operational stability and durability. At the same time, they are also relatively easy to maintain and clean to ensure the normal operation and extended service life of the equipment.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

Powder bucket elevators are designed to minimize product degradation during transportation by employing various features and techniques. Here's how they can help in minimizing product degradation:

1.Gentle Handling: Powder bucket elevators are specifically designed to handle powders or granular materials gently. The buckets or cups used in the elevator are often constructed with smooth surfaces and may have additional features such as flexible or low-friction materials. This design minimizes the impact and friction between the material and the buckets, reducing the risk of product breakage or damage.

2.Customizable Bucket Design: The bucket design can be customized to match the characteristics of the powder being handled. For materials that are prone to degradation or breakage, the bucket shape, size, and materials can be adjusted to minimize product attrition. Smooth and rounded bucket shapes, as well as the use of materials with low abrasiveness, can help reduce product degradation.

3.Controlled Speed and Flow: Powder bucket elevators allow for controlled speed and flow of materials. The speed of the elevator can be adjusted to ensure a gentle and consistent movement of the powder. Controlling the flow rate helps prevent material impacts and collisions within the elevator, reducing the chances of product degradation.

4.Minimizing Dust Generation: Dust generation during transportation can contribute to product degradation. Powder bucket elevators often incorporate dust control measures such as enclosed or sealed systems, dust collection ports, or integrated dust collectors. These features help in reducing dust emissions and minimizing the contamination and degradation of the product due to airborne particles.

5.Preventing Segregation: Segregation, the separation of different particle sizes or components within the powder, can lead to product quality issues. Powder bucket elevators can be designed to minimize segregation by maintaining an even distribution of particles throughout the material flow. Proper bucket design and spacing can help prevent particle segregation during transportation.

6.Minimizing Spillage: Product spillage can occur during material transfer, leading to product degradation and loss. Powder bucket elevators are designed to minimize spillage by incorporating features such as tight bucket-to-bucket sealing, controlled discharge points, and appropriate bucket filling techniques. These measures reduce the chances of product exposure to external factors that could cause degradation.

| Client's name | Industry | Application | Conveying capacity | Lift height |

| **Food Processing Company | food processing | Flour and powdered sugar transportation | 5 tons/hour | 10 m |

| **Chemical Company | Chemical industry | Pigments and chemical powder transportation | 3 tons/hour | 15 meters |

| **Pharmaceutical factory | pharmaceutical | drug powder delivery | 2 tons/hour | 8 meters |

| **Mining Company | mining | Lime powder conveying | 10 tons/hour | 20 meters | **Building Materials Company | Building materials | Cement and gypsum transportation | 8 tons/hour | 12 meters |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.