Specifically designed and used in the cement industry for the handling of cement or similar materials to transport bulk materials (such as cement, clinker or fly ash) from one level to another within a cement plant.

![]()

![]()

Price:::$550.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Delivery capacity: 5.4-365 cubic/hour

Lifting height: 40 meters

Equipment material: carbon steel, stainless steel

Material temperature: ≤250℃

Bucket capacity: 5.2~10L

Bucket speed: 1.25m/s

Motor power: 5.5~7.5KW

Application: It is mainly used to lift bulk materials such as cement from low to high to meet the production needs of cement factories.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

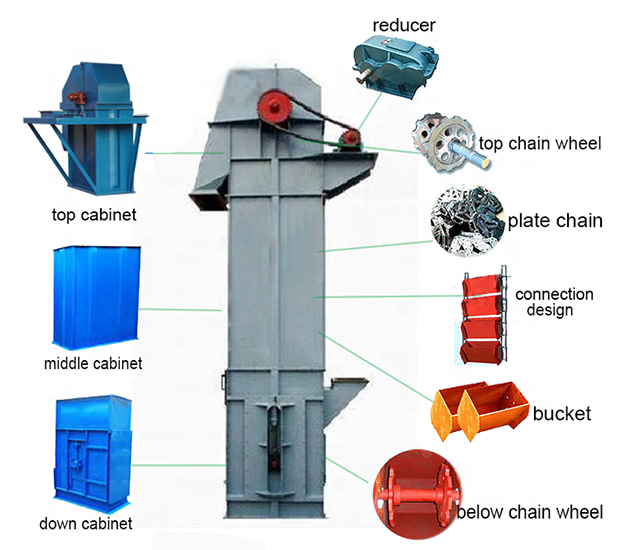

Cement bucket elevator is a type of bucket elevator specifically designed for the vertical transportation of bulk materials in the cement industry. It is commonly used to transport cement, clinker, and other powdered or granular materials in cement plants and related facilities.

Cement bucket elevators are essential for efficient and reliable material handling in cement production facilities. They enable the vertical transportation of bulk materials, allowing for smooth and continuous processes throughout the cement manufacturing process.

In the cement industry, there are several types of bucket elevators commonly used:

Centrifugal Discharge Bucket Elevators

Centrifugal discharge bucket elevators are the most common type used in the cement industry. They operate at high speeds and use centrifugal force to discharge the material from the buckets into the discharge chute or another conveying system.

Application: Suitable for handling fine to medium-sized materials with moderate abrasiveness.

Continuous or Gravity Discharge Bucket Elevators

Unlike centrifugal discharge elevators, they operate at lower speeds and rely on gravity to discharge the material. The buckets are closely spaced to prevent material from spilling back into the boot section.

Application: Used for handling materials such as clinker or materials with high moisture content.

TD Vertical Belt Bucket elevator

TD vertical belt bucket elevator is a common material conveying equipment, suitable for vertical or inclined material lifting. It has the characteristics of simple structure and reliable operation.

Application: chemical fertilizer,diabase, bentonite and other powder, granular or block products.

Cement bucket elevators are widely used in the cement production process and are mainly used in the following aspects:

Raw material lifting: Cement bucket elevator can lift raw materials such as limestone, clay, etc. from low places to crushers, mills and other equipment to achieve continuous supply of raw materials.

Clinker lifting: The cement bucket elevator lifts the clinker (calcined raw material) from the bottom of the kiln to the cooler or storage bin for cooling and storage.

Pulverized coal lifting: Pulverized coal is commonly used as fuel in cement production. The cement bucket elevator can lift pulverized coal from the pulverized coal bunker to pulverized coal combustion equipment, such as coal mills or rotary kilns.

Cement transportation: The cement bucket elevator can lift cement from the cement mill to destinations such as cement storage bins or concrete mixing stations to ensure smooth transportation and storage of cement.

Waste material treatment: Cement production will produce some waste materials, such as kiln dust, coal ash, etc. The cement bucket elevator can be used to lift these waste materials to processing equipment or waste material storage areas to achieve effective treatment and utilization of waste materials.

Efficient vertical conveying

Cement bucket elevators are designed for vertical conveying and can efficiently transport bulk materials between different floors within a cement plant. They can handle large volumes and lift materials to significant heights, optimizing the entire material handling process.

Space-saving design

Bucket elevators are compact in design and require a relatively small footprint compared to other types of conveyor systems. This is particularly beneficial in cement plants where space is often limited. The vertical orientation of the elevator helps maximize the use of available floor space.

Reduce labor requirements

Bucket elevators automate the process of moving materials vertically, reducing the reliance on manual labor for material handling tasks. Efficiency, productivity and cost savings can be increased by minimizing the need to manually load, unload and transport materials between different factory areas.

Minimize material loss and spillage

Cement bucket elevators are designed to minimize material loss and spillage during transportation. The bucket is engineered to hold material securely and prevent spills or leaks. This helps maintain a clean, safe working environment and reduces product waste.

Improve security

Bucket elevators come with various safety features to ensure operator health and prevent accidents. These include emergency stop systems, guards, access doors and sensors to monitor operating conditions. By promoting a safer working environment, bucket elevators help improve the overall safety standards of cement plants.

Durability and reliability

Cement bucket elevators are designed to withstand the harsh conditions and abrasive nature of cement and other bulk materials. They are constructed from heavy-duty materials and components to withstand the rigors of continuous operation, minimizing downtime and maintenance requirements. Reliable operation reduces interruptions in the production process and increases overall productivity.

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

Here are some key features and considerations for cement bucket elevators:

Load Capacity: There are different sizes and load capacities available to suit the specific requirements of cement plants. Carrying capacity is determined based on material flow requirements, material properties, and required vertical height.

Design and Construction: Cement bucket elevators typically feature a reinforced bucket, strong belts or chains, and a sturdy casing to withstand the weight and wear of the cement. Wear-resistant liners or coatings may also be used in areas subject to wear.

Lifting height and tilt angle: Lifting height depends on the layout and requirements of the cement plant. The design of the elevator should consider factors such as available space, required material flow and specific process requirements.

Dust Control: Cement production can generate large amounts of dust, so appropriate dust control measures need to be taken.

1. Heavy Duty Construction: Cement Bucket Elevators are constructed of strong and durable materials that can withstand the harsh and abrasive nature of cement and other bulk materials. Casings, buckets and support structures are typically constructed of high-strength steel or wear-resistant materials to ensure long-term reliability and minimize maintenance needs.

High-capacity design: Cement production requires the vertical transportation of large amounts of material, so cement bucket elevators are designed to handle high capacities. They feature larger buckets and wider belts or chains than standard bucket elevators to efficiently and continuously transport bulk materials.

2. Specialized buckets: The buckets used in cement bucket elevators are designed to efficiently handle cement and other abrasive materials. They are usually made of wear-resistant materials, such as hardened steel or rubber, to withstand the wear and tear caused by transported materials. Bucket designs may also have reinforced corners or additional linings for added durability.

3. Reinforced Belts or Chains: The belts or chains used in cement bucket elevators are specially reinforced to handle the heavy loads and abrasiveness of cement. It is usually made of high-strength steel wire rope or hardened alloy chain to ensure reliable and long-lasting operation.

4. Dust prevention: Cement transportation will generate a lot of dust, so the cement bucket elevator is equipped with a dust prevention system to minimize dust emissions and maintain a clean and safe working environment. These systems may include dust covers, seals and dust collection ports to prevent dust from escaping during operation.

5. Discharge chute and distribution system: On the top of the cement bucket elevator, there is a discharge chute to guide the material to the desired location, such as a storage bin or other conveyors. Depending on the application, distribution systems such as rotary distributors or discharge spouts can be incorporated to evenly distribute material to multiple storage or processing points.

How Industrial Sifter Helped Different Industries:

Cement Manufacturer

Many cement manufacturers use cement bucket elevators to handle raw materials and finished cement. For example, a large cement manufacturer may use cement bucket elevators to transport raw materials such as limestone and fly ash to grinding equipment, and finished cement to storage or loading equipment.

Construction Company

Construction companies use cement bucket elevators on construction sites to deliver cement and other building materials. These hoists can lift cement from ground storage tanks or transport vehicles to elevated areas in construction areas for concrete mixing, masonry or other construction needs.

Concrete Manufacturer

Concrete manufacturers usually use cement bucket elevators to transport raw materials such as cement, sand, and aggregate to concrete mixers. These hoists are able to lift raw materials from the floor or storage equipment to the feed opening of the mixer to ensure the continuity and efficiency of the production process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.