Lithium cobalt oxide (LiCoO₂) is an important cathode material for lithium-ion batteries, and its particle size distribution has an important impact on battery performance. In the production process of lithium cobalt oxide, lithium cobalt oxide ultrasonic vibrating screen is used for screening and grading. Vibration and ultrasonic technology are used to ensure that the particle size distribution of lithium cobalt oxide powder is uniform, meeting the production requirements of lithium-ion battery cathode materials, ensuring uniform particle size, and improving product quality.

①Chemical formula: LiCoO₂

②Color: black-gray powder

③Application: Mainly used as the positive electrode material of lithium batteries, it has the advantages of high operating voltage, stable discharge, high specific energy, and good cycle performance. However, it has high cost, poor safety, and average cycle life and material stability.

④Safety: Lithium cobalt oxide is toxic and needs to be screened after preparation before it can be used. During the screening process, it needs to be strictly sealed to prevent dust leakage.

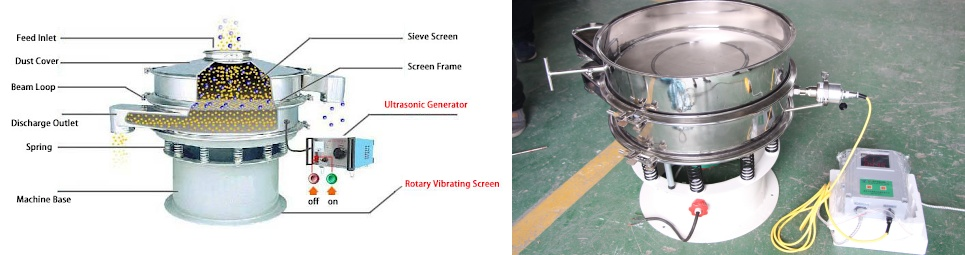

1、Vibration Generation:Like standard vibrating screens, it uses a vibration motor or exciter to generate mechanical vibrations.These vibrations cause the screen mesh to move, typically in a circular or elliptical motion.

2、Material Movement:The vibrations cause lithium cobalt oxide powder to move across the screen surface.Particles smaller than the mesh openings pass through, while larger particles are retained.

3、Layering and Separation:The vibrations also help to stratify the powder, with finer particles settling towards the mesh and larger particles rising.

1. Ensure the cleanliness and uniform particle size of lithium cobalt oxide: Lithium cobalt oxide ultrasonic vibrating screen avoids the pollution of lithium cobalt oxide by powder produced by wear of traditional net cleaning devices through efficient net cleaning effect. The particle size of the screened material is relatively uniform, which meets the particle size requirements of lithium batteries for lithium cobalt oxide powder.

2. Prevent lithium cobalt oxide dust leakage: Lithium cobalt oxide is toxic, so dust leakage must be strictly prevented during the screening process. Lithium cobalt oxide ultrasonic vibrating screen adopts a sealing design, and the screen frame is fixed with sealing strips and beam rings to ensure that dust will not escape during the screening process.

3. Solve the problem of lithium cobalt oxide agglomeration and net blocking: Lithium cobalt oxide powder is prone to agglomeration or net blocking due to static electricity, adhesion, agglomeration and other factors during transportation and screening, thereby effectively solving the agglomeration and net blocking problems of lithium cobalt oxide powder.

4. Solve the viscosity problem of lithium cobalt oxide: For materials with strong viscosity such as lithium cobalt oxide, lithium cobalt oxide ultrasonic vibrating screen can reduce the adhesion between particles through the action of ultrasound, improve screening efficiency, and reduce adhesion problems.

1. Battery material production: In the production process of lithium cobalt oxide battery materials, lithium cobalt oxide ultrasonic vibrating screen can be used to screen and grade lithium cobalt oxide powder to ensure uniform particle size and improve battery performance.

2. Catalyst preparation: Lithium cobalt oxide ultrasonic vibrating screen can be used to screen lithium cobalt oxide powder as a catalyst, remove impurities, and improve the purity and activity of the catalyst.

3. Ceramic material production: Lithium cobalt oxide also has certain applications in ceramic materials, such as ceramic pigments, ceramic coatings, etc. Lithium cobalt oxide ultrasonic vibrating screen can help accurately screen lithium cobalt oxide particles to ensure the quality and uniformity of ceramic materials.

4. Material research and development and production: Lithium cobalt oxide ultrasonic vibrating screen can be used for particle size analysis, screening and grading of materials to help optimize the performance and quality of materials.

Lithium cobalt oxide ultrasonic vibrating screen is a high-precision and high-efficiency screening equipment that plays an important role in battery material production and quality control. Correct selection, operation and maintenance can ensure long-term stable operation of the equipment and improve production efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.