The production and processing of fruit juice generally needs to go through the process of picking → sorting → cleaning → crushing and peeling → juicing → coarse filtration → deployment → filtration → homogenization → degassing → sterilization → filling and sealing → sterilization → cooling inspection → packaging finished products , The food vibrating sieve is mainly used in the coarse filtration and filtration stage in the juice processing, and is used to separate the remaining fibers, pulp, seeds and other impurities in the juice from the juice, so as to ensure the taste and quality of the juice.

The food vibrating sieve for fruit juice removal is made of stainless steel, and the types can be divided into two types: rotary vibrating sieve and 450 filter sieve.

The former rotary vibrating sieve is suitable for large-volume juice production lines, and is usually used with large juicers, vacuum feeders and other equipment to form an automated juice production line.

The latter 450 sieves are mostly used for small-volume production or household use. The models are compact and occupy little space. The total weight of the machine does not exceed 50kg, which is convenient for storage.

The food vibrating sieve used for fruit juice removal and filtration is usually designed with a higher feed inlet at the upper end, in order to avoid pollution and waste caused by juice splashing, and use a waterproof motor to ensure production safety.

The advantages of juice filtration and impurity removal vibrating sieve are as follows:

1. Good sealing. Liquid filtration is the basis for no leakage. Fruit juice filtration food vibrating sieves are sealed with food-use silicone sealing rings to ensure no leakage.

2. Automatic nesting. The juice filter food vibrating sieve is a single-layer design, with discharge ports on the upper and lower layers, the upper layer can automatically discharge impurities, and the lower layer can automatically discharge juice.

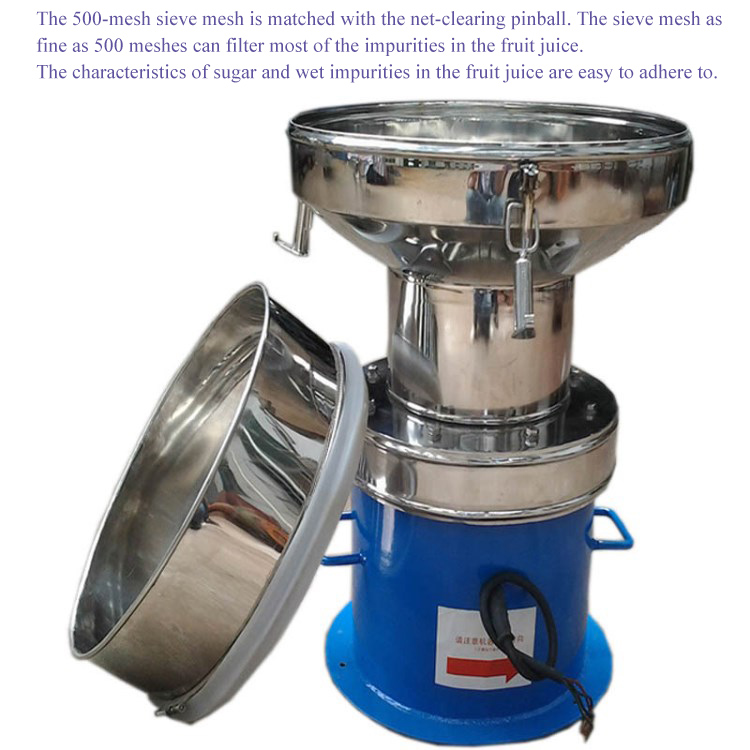

3. The 500-mesh sieve mesh is matched with the net-clearing pinball. The sieve mesh as fine as 500 meshes can filter most of the impurities in the fruit juice. The characteristics of sugar and wet impurities in the fruit juice are easy to adhere to.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.