Separators for the continuous removal of solids from liquid slurries.

![]()

![]()

Price:$420.00-$600.00/Set

Consult now and enjoy a 10% discount

Mesh size: within 400 mesh

Capacity: 400-1200 kg/h

Layer(s): 1 Layer

Voltage: 220V/380V or as your request

Material: Stainless Steel 304

Frequency: 50/60 Hz

Application materials: ink, color paste, paint, latex paint, soybean milk, fruit juice, beverage, dairy products, pulp, waste liquid, Chinese and Western medicine liquid, etc

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

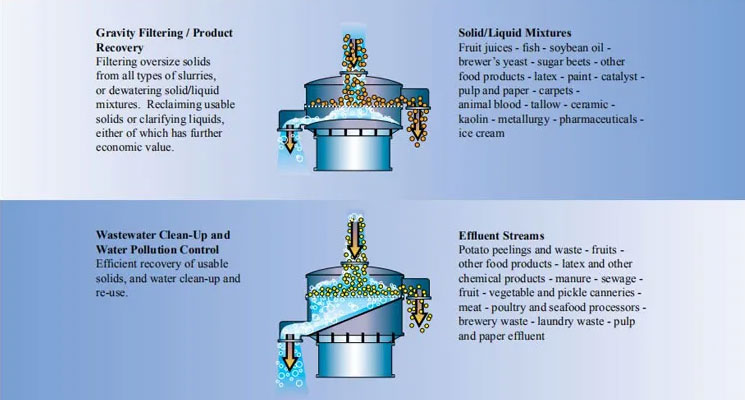

Solid liquid separator is a sieve or filter used to separate solid particles from a liquid mixture. It consists of a mesh or perforated surface that allows liquids to pass while retaining solid particles and is commonly used in wastewater treatment, food and beverage processing, and other industries that require the removal of solid particles from liquid streams.

Solid liquid separators are used in a variety of industries including wastewater treatment, food and beverage processing, pharmaceuticals, chemicals and mining. For example, in wastewater treatment, screens are used to remove solid particles such as grit, sand, and other debris from incoming wastewater streams. In food and beverage processing, sieves are used to remove solids such as pulp, seeds and peels from liquids such as juice and wine.

Solid-liquid separation: can effectively process solid mixture materials, quickly realize solid-liquid separation, and filter out materials of different meshes.

Impurity removal: It can remove small parts of different sizes in a large amount of liquid materials for rapid separation.

There are several types of solid liquid separators available, each with its own characteristics and applications. Some common types of sieves used for solid liquid separator include:

| Type | Vibro Sifter | Filter Sieve | High Frequency Vibrating Screen |

|

|

|

|

| Features | It adopts the edge design (the upper frame is heightened) to prevent the splashing of liquid materials, and it is also convenient to observe the operation of materials on the screen surface at any time. | It is suitable for single-layer screening and filtering of manufacturers in various industries. It can handle materials with small production volume or less impurities and good fluidity. It is a screening and filtering equipment for small and medium-sized enterprises. | It adopts a 2-stage high-frequency vibration motor with a speed of 3000 rpm, which is suitable for viscous slurry, such as ceramic glaze, mud, paint, etc. |

| Mesh size | 5 microns | 400 mesh | 30mm |

| Capacity | 100-3300kg/h | 400-1200kg/h | 5-48 tons/hour |

Solid liquid separator work by using a mesh or perforated surface to separate solid particles from a liquid mixture. The sieve allows the liquid to pass through while retaining the solid particles on the surface.

The size and shape of the openings in the sieve can be customized to suit the specific application, allowing sieves to be designed to handle a range of particle sizes and flow rates.

Solid liquid separator is to dehydrate the liquid in the solid-liquid mixture or remove impurities in the liquid, which partially replaces the function of the centrifuge. It is generally used in industries such as fruit juice, dairy products, Chinese and Western medicine liquid extraction, paint filtration, waste water recycling, etc.

| The following are some common applications of solid-liquid separation: | |

| Handling Products | Purpose of Usage |

| Soy milk | It can remove impurities in soy milk, and the filtered soy milk tastes better |

| Juice | Quickly and efficiently sifts pulp from purees, increasing productivity and ensuring clear, pulp-free juices, removing oversized solids |

| Domestic sewage | Remove hair, shampoo foam and some plastic bags in the domestic waste water |

| Calcium Hydroxide Slurry Filtration | Prevent small solid particles from clogging the nozzle during spraying with the nozzle, so filter out the coarse solid particles with a size of 12 mesh |

| Ceramic glaze | Filter ceramic glaze or ceramic slurry to remove impurities |

Slurry solid liquid separator

Latex paint solid liquid separator

SUS304 stainless steel material

Made of stainless steel (304), it has the characteristics of corrosion resistance and rust resistance, especially suitable for slurry filtration.

Increased design

The heightened design of the screen frame can effectively prevent the slurry from splashing out during the separation process and protect the environment.

Fast delivery

The large diameter discharge channel can handle 1200kg per hour, the discharge is fast and the material is not easy to accumulate.

Anti-seepage

The motor with waterproof grade IP54 + anti-seepage water treatment, the slurry does not leak, the operation is safer, and it can prevent the damage to the motor caused by liquid.

Automation

The 360-degree automatic spray head is used alone, and the screen is cleaned 100%, and it is automatically cleaned (prepared according to the characteristics of the material).

Available options

The discharge port can be equipped with a control valve to control the flow and achieve the purpose of quantitative separation.

| Model | Power (kW) |

Whole machine size (mm) |

Sieve body size(Diameter*Height) (mm) |

Weight (kG) |

Description |

| DH-450 | 0.18 | 500*500*600 | 488*135 | 40 | The seat material is Q235 high quality carbon steel, stainless steel can be selected according to needs |

| DH-450s (With mobile trolley) |

500*500*1000 | 48 |

The standard model of Solid Liquid Separator has a size of 360×300×470mm and a weight of only 42kg. The part in contact with the material to be filtered is made of stainless steel. The mesh size of the screen is 5-400 mesh, and the diameter of the effective screen surface is 400mm. , The overall space is not large, it can be retracted at will, and other sizes can be designed according to the needs.

Small trolley base: easy to move and adapt to frequent changes in the filtering site, and can be retracted quickly;

Elevated base: match the height of the feeding equipment to avoid material splashing due to excessive drop between the screen surface and the feeding equipment;

Open discharge port (conventional discharge port): filter materials with good fluidity and few impurities, and discharge quickly;

Valve outlet: Closeable valve switch, suitable for viscous or pseudo-caking materials with poor fluidity and difficult to sieve, can close the valve to prolong the time for materials to be filtered in the net, and improve the screening accuracy;

Tube type discharge port: easy to splash liquid or extremely light, fluidity powder material, reduce splashing and scattering.

Other designs can be adjusted according to specific filtration requirements, such as adding iron remover, dust collector, observation window cover, special material, special motor or machine color, etc.

Solid-liquid Separation Examples

Solid liquid separator is a common process in many industries, and there are numerous examples of its use. Here are a few examples:

1. Wastewater treatment: One of the most common applications of solid-liquid separation is in wastewater treatment. In this process, solid particles such as grit, sand, and other debris are removed from the incoming wastewater stream using screens, sedimentation tanks, and filtration systems.

2. Food and beverage processing: Solid-liquid separation is used in the food and beverage industry to remove solids such as pulp, seeds, and skins from liquids such as juice and wine. This is typically achieved using screens, filtration systems, and centrifuges.

3. Mining: Solid-liquid separation is used in the mining industry to separate solid particles from slurries. This is typically achieved using vibrating screens, cyclones, and centrifuges.

4. Chemical processing: Solid-liquid separation is used in the chemical industry to remove impurities from liquids, such as removing catalyst particles from chemical reactions. This is typically achieved using filtration systems, centrifuges, and sedimentation tanks.

5. Oil and gas production: Solid-liquid separation is used in the oil and gas industry to remove solids such as sand and other debris from produced water and drilling muds. This is typically achieved using screens, hydrocyclones, and centrifuges.

| Materials | Materials img | Mesh size | Capacity |

| soy milk |  |

120 mesh, 160 mesh | 1200 liters/hour |

| juice |  |

40 mesh,80mesh | 6-10 cubic/hour |

| lotion |  |

600 mesh | 1 ton/hour |

| pomegranate juice (seeds and juice separated) |  |

100 mesh | 5 tons/hour |

| spray paint |  |

325 mesh | 1200 liters/hour |

How solidliquid separators are applied to different industries:

Filter soy milk

It can be used to filter and remove impurities from soy milk, and its efficiency is much higher than that of traditional soy milk, ensuring that a small amount of bean dregs or other impurities are mixed into the soy milk, and the filtered soy milk tastes better.

Filter latex paint

Various impurities and large particles are removed by vibrating screening and filtering equipment, and the finished coating is packaged.

Pulp solid-liquid separation

Using a solid liquid separator to filter, recycle the pulp, remove harmful substances in the water and then discharge them, is also conducive to environmental protection.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.