For many processing industries, whether it is to use a self cleaning filter for solid suspended in liquild, this may be the biggest confusion. The liquid filtration process is used to remove suspended solid particles from the liquid using a filter medium. The filter media passes the fluid through and retains the solid particles. Both solids and liquids can be the desired particles for use in the production line.

A self cleaning filter is a device for solid suspended in liquild.

Continuous operation and self-cleaning: Self-cleaning filters can be filtered for long periods of time without any downtime. The mechanism of the self-cleaning filter is designed to automatically provide you with regular cleaning at the scheduled time. The cleaning disk moves along the filter basket to remove oversized particles along the perimeter.

High throughput: It can filter up to 400 mesh slurry materials, 325 mesh paint with a specific gravity of 1.1, and the output per hour can reach 1200 liters. The sieved 30 mesh flour can handle 700 kg per hour.

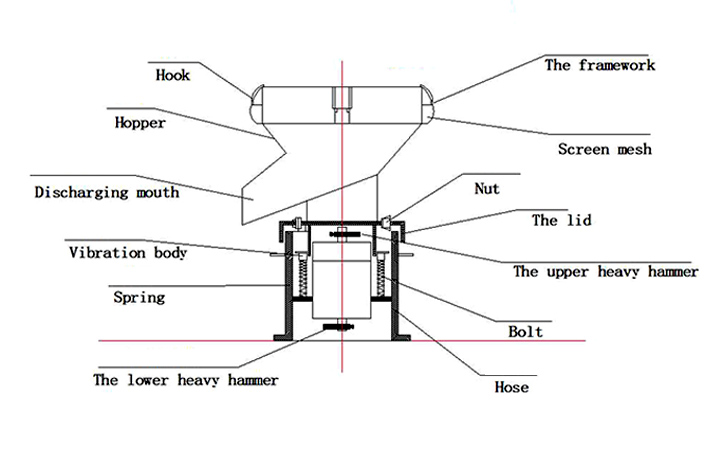

Closed system: The system is completely enclosed and there are no leaks. It features advanced sealing components for more precise filtration of the product. The shaker also gives you a closed system with an observation point.

Safe and reliable: When sieving liquid, the vibrating screen motor will always be damaged, because the liquid is contaminated by the motor when filtering the liquid, or it may be because of the large liquid flow, high output requirements, long-term high-load use,motor pressure is large, causing burnout. Our liquid filter screen adopts IP54 waterproof grade vibration motor, which can reduce the problem of self-cleaning filter.

High-viscosity materials: Self leaning filters are best suited for high-viscosity materials because they push the material to filter under pressure differentials.

Therefore, please don't be confused, and ask Dahan Machinery to help you find the equipment that best suits your product.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.