Specifically designed for high volume screening of powders and liquid slurries in the food industry to remove oversize and contaminants

![]()

![]()

![]()

Price:$550.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400/800/1000/1200/1500/1800/2000 mm

Mesh size: 2-500 mesh Capacity: 100-3300kg/h

Layers: 1-5 layers

Voltage: 220/380V Power: 0.18-2.2kw

Material: Stainless Steel (304/316L)

Application: Screening and filtering of fine powders, granules and dry and wet materials in the food industry, such as: flour, spices, wheat, sesame, chili powder, cocoa powder, coffee powder, seasoning, salt, soy milk, juice, etc.

Commitment:

Food vibrating sieve can divide various raw materials (such as flour, milk powder, soybean milk) and various primary products (corn, wheat, spices) into several particle size grades according to different components, or remove fine powder, solid particles or Agglomeration and other impurities, the following shows you the application of vibrating sieve in the food industry:

Food vibrating sieve can sieve up to 500#, the equipment is made of high-quality SUS304 or 316L stainless steel, mirror-polished, the inner and outer surface finish is 0.1-0.2 RA, to ensure that the sieving raw materials will not be contaminated, all rubber parts are silicone food grade The fully enclosed structure ensures dust-free operation.

1. In the flour and instant noodle industry, vibrating sieve is mostly used for impurity removal and loosening. For example, a food vibrating sieve with a size of 1000mm and a mesh size of 12 meshes can be used to sieve and remove impurities from loose wheat flour when making instant noodles, and it can reach 350Kg/150 seconds.

2. Vibrating sieve for fruit juice industry

In the fruit juice industry, the vibrating sieve is mostly used for the filtration and separation of pulp and juice. Depending on the type of fruit and the requirements of the production process, the number of sieve meshes is mostly between 40-100 mesh, and models such as DH-1800-1S, DH-1500-1S, DH-1200-1S, and DH-1000-1S are mostly used. The output of vibrating sieve is about 5-20 cubic meters. When making fruit and pulp beverages, the sieve hole diameter is relatively large, generally around 6-4mm.

3. Vibrating sieve for starch industry

The starch industry uses vibrating sieve, which is generally used for loosening, impurity removal, and screening. The process is generally divided into dry powder screening and starch milk filtration. When sieving dry powder, the mesh number is mostly between 40-120 mesh, and when filtering, the mesh number is relatively high, up to 200-325 mesh.

4. Vibrating sieve for food additive industry

The vibrating sieve used in the food additive industry is generally used for loosening, impurity removal, and sieving, and the mesh number of dry powder sieving is mostly between 20-200 mesh.

5. Vibrating sieve for condiment industry

The vibrating sieve used in the condiment industry is generally used for loosening, impurity removal, sieving, and filtering. When sieving dry powder condiments, the mesh number is mostly between 20-200 mesh. In the production of liquid seasoning, it is mostly filtered, and the mesh number is between 40-100 mesh.

6. Vibrating sieve for dehydrated vegetable industry

The vibrating sieve used in the dehydrated vegetable industry is generally used for impurity removal and screening. The number of sieve mesh depends on the process requirements, generally between 10mm-2mm.

Whether it is clarifying, grading, sorting, dusting or de-clumping, food vibrating sieve can divide various raw materials (such as flour, milk powder, soy milk) and various primary products (corn, wheat, spices) into several parts according to particle size grade, or remove moisture, impurities, etc., for further processing, which can help you produce delicious and safe products.

All of our food production screening equipment and screens are specially designed for easy cleaning and maintenance. They are available in a variety of sizes and materials and are capable of performing light and heavy duty applications.

Ingredients: Mixed foods, flour, wheat, bread, butter, beef, chocolate, chocolate liquor, dehydrated foods, honey, ice cream, flavors and seasonings, plant-based meat substitutes, tofu, fruits and vegetables, syrups and molasses, yeast , Spices, Pet Food, Animal Feed

Some of the food processing businesses we support include: Meat Products\Dairy Products\Supplements\Preserved Fruits and Vegetables\Grains\Pastry\Bakery\Fats and Oils\Tea and Coffee\Other Beverages

SUS304/316L stainless steel, easy to clean

Made of high quality stainless steel, namely SS 304 and 316L, mirror polished with 0.1-0.2 RA surface finish inside and outside, ensuring no material deposits, not easy to contaminate raw materials, and easier to clean.

Sieve to 500 mesh

Ensure the high quality of your product by eliminating potential contaminants, it is suitable for sieving from 10 mesh (1.7mm) to 500 mesh (0.025mm) and provides the required output to provide accurate particle size.

Clean, hygienic and pollution-free

All rubber parts are silicone food grade and welded joints are seamless for hygienic and contamination-free operation.

Closed system

The fully enclosed construction eliminates airborne dust problems and avoids any chance of cross-contamination between batches.

Easy to maintain

Easy-to-disassemble design for quick maintenance without tools.

Small footprint

The compact design allows the screening machine to be easily installed in any production line.

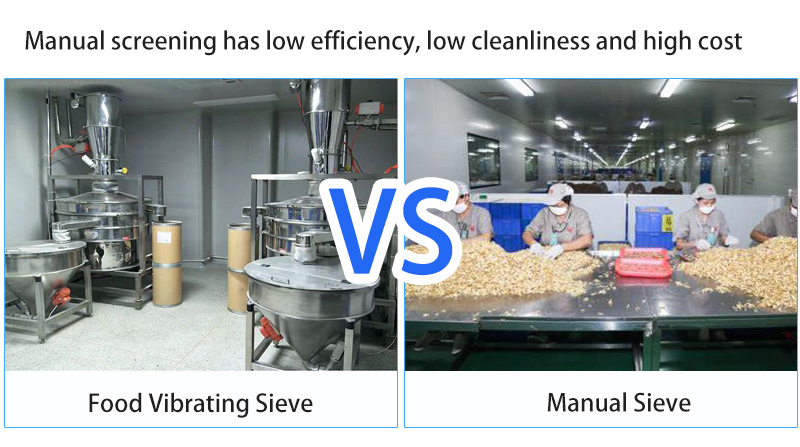

| Compare items | Food Vibrating Sieve | Manual Sieve |

| Processing material (salt) | ||

| Output | The output of a single special screen is 350 kg/h | Manual screening 100 kg/h per person |

| Performance | The special sieve can work continuously for 24 hours to ensure that there will be no pollution, hair and other sundries will be mixed in | Manual sieving and continuous shaking for 1 hour will cause overwork, and impurities will be mixed into the pellets intentionally or unintentionally. |

| Cost | Machine unmanned screening, can be used for a long time | According to the output of a granulator of 350kg/h, 4 workers need to be employed to shake the sieve, the per capita wage is about 150 per day, and for 300 working days per year, the annual labor cost is 150 × 4 × 300 equal to 180,000 yuan |

| Efficiency | The special sieve has more uniform sieving particle size, and the accuracy can reach more than 95% | Manual screening accuracy is unstable, the longer the working time, the lower the accuracy |

| GMP standard | meets | incompatible |

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

We can manufacture equipment and screens in standard configurations, or we can create custom solutions based on your specific processing, space and logistical requirements.

Food vibrating sieve is composed of feed inlet, dust cover, discharge outlet, beam ring, screen mesh, vibrating motor, spring, machine base and other parts. The material of the sieve machine is generally required to be made of 304 stainless steel for the part in contact with the material, and it is also used All made of stainless steel.

Vibrating screen accessories must use silicone material. Points, no burrs, these are all in order to meet the requirements of sanitary conditions.

The number of screen mesh and the number of outlets: the food industry generally screens powdery and flake materials. During the screening process, the materials can be classified according to different particle sizes by adding multiple outlets to achieve the screening level required by users. need. For example: in the production of flour, the flour needs to be sifted into 120 mesh and fine materials at the initial stage. The primary raw materials of flour are condensed from powdery materials with the same mesh size, and the difference in powder size will affect the coagulation and affect it as much as possible. Product quality, vibrating sieve can evenly distribute materials with different particle sizes in each layer to achieve the goal. After the flour is successfully produced, the classification of flour also needs to be processed by vibrating sieve. Different grades are divided into multiple materials, and unqualified defective products are re-made and re-screened.

| Application of Food vibrating sieve in food industry | |||||

| Materials | Proportion | Mesh | Model | Methods | Capacity |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 T/h |

| Corn starch | 0.6 | 40 | DH-1000-1S | Dry | 1600㎏/h |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏/h |

| Yeast liquid | 0.5 | 32 | DH-1000-1S | Wet | 8000 T/h |

| Rice flour | 0.5 0.8 | 100 | DH-1000-1S | Dry | 300 ㎏/h |

| Soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 T/h |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏/h |

| Pollen | 0.4 | 12 | DH-1500-1S | Dry | 100㎏/h |

| Tofu | 1 | 120 | DH-1000-1S | Wet | 2500 T/h |

| Sweetener | 0.7 | 40/80 | DH-800-2S | Dry | 320㎏/h |

| Granulated sugar | 1.2 | 12 | DH-1500-1S | Dry | 8000㎏/h |

| Pineapple juice | 1 | 100 | DH-1000-1S | Wet | 3000㎏/h |

| Skim milk powder | 0.57-0.7 | 24 | DH-1200-1S | Dry | 3000㎏/h |

| Rice bran | 0.5 | 16 | DH-800-1S | Dry | 500㎏/h |

| Powdered sugar | 0.5-0.8 | 100 | DH-800-1S | Dry | 200㎏/h |

Dahan Machinery has a wide range of vibrating screens, separators and liquid filters, all of our screening equipment for the food and beverage industry are manufactured in accordance with FDA (food) and ATEX (explosion-proof) standards and feature high specification satin/mirror finishes Made of polished stainless steel.

Our sieving and filtration screens have effectively helped many customers overcome food processing separation and filtration problems, including well-known brands such as Yonghe Soymilk, Coco-Cola, Sinian Foods, Haitian Seasoning Foods, and smaller independent food processing companies.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.