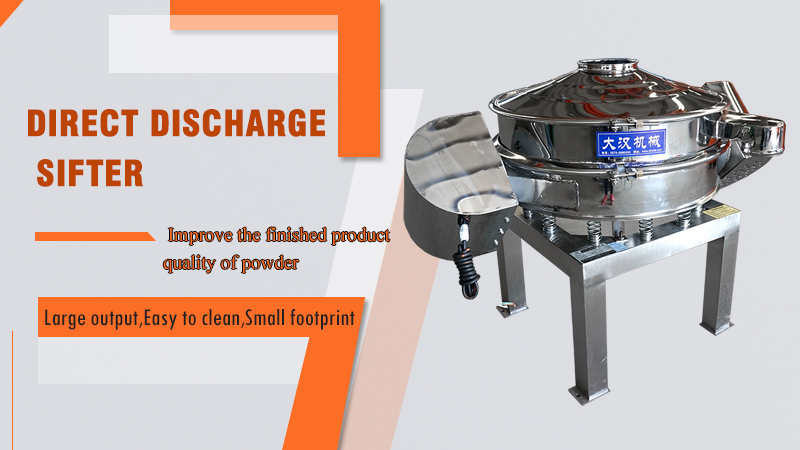

Direct discharge sifter can perform simple safety screening and accurate grading of powders or granules. The more common applications are flour, washing powder, rice flour, graphite powder, metal powder and other production lines. This article will introduce the direct discharge sifter in the powder production line. The advantages.

1. Improve the finished product quality of powder

Whether you are a small artisan bakery or a large industrial flour mill, the direct discharge sifter can be used to safely remove contaminants and agglomerates from powder.

2. Large output

The water inlet and outlet are designed in the same vertical direction, and the large flow outlet at the bottom enables the material to be discharged directly, which is beneficial to increase the discharge volume, and the processing capacity is 2-5 times that of the ordinary circular screen.

| Materials | Way of working |

Screen (mesh) |

Capacity | Model |

| milk powder | dry | 16.2 | 2000 | ZPS-800 |

| starch | dry | 80 | 1200 | ZPS-600 |

| wheat starch | wet | 200 | 3200 | ZPS-1000 |

| flour | dry | 24 | 1500 | ZPS-1500 |

3. No dust

The direct discharge sifter can be directly used in series in the pipeline to remove impurities such as excessively large pollutants, without manual operation, with good air tightness and no powder flying. It can be used directly with the vacuum feeder to achieve negative pressure and dust-free operation. .

4. Easy to clean

It can be disassembled quickly without any tools and is easy to clean, thus increasing productivity and avoiding any chance of cross-contamination between batches.

3. Small footprint

Compact size, small footprint, in addition, the direct discharge sifter motor is designed on one side or both sides of the equipment (single vibration source and double vibration source direct discharge sifter can be selected according to actual needs), which reduces the height of the equipment, effectively utilizes space, and meets the needs of Industrial and commercial needs, adaptable to any production line.

4. Easy to operate

In addition to its small footprint, the direct discharge sifter is also completely portable, allowing one unit to be used in different locations in your facility.

The above is an introduction to the advantages of direct discharge sifter in powder production line. This high-capacity direct discharge sifter can be installed under bulk silo for safe screening of powder, and can also be pneumatically conveyed from tanker or rail car receiving operations to Check the incoming feed after delivery and can also be installed in bakeries and food processing plants of all sizes. In addition, the direct discharge sifter can be used with the feeding station (dust-free feeding station) to unload and inspect small or extra large bags of flour to avoid dust problems in sifting.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.