Ultrasonic vibrating sieve is a common type of fine screening. However, due to the ultrasonic transducer, it can better solve the problem of blocking the net of light specific gravity and high static electricity compared with ordinary vibrating sieve. The screening efficiency is extremely high, and we will introduce you to the ultrasonic vibrating sieve.

Ultrasonic vibrating sieve is a simple, practical and reliable screening system. It is the most effective screening equipment for solving the current screen clogging. After understanding the function of the product, it must also understand its structure, product structure and product appearance. Compared with a certain complexity, today I will take you to understand the internal structure of the ultrasonic vibrating sieve, so as to better facilitate the user to purchase and purchase a better ultrasonic vibrating sieve.

The ultrasonic vibrating sieve is mainly composed of a dust cover, a screen frame, a screen mesh, an ultrasonic device, a vibration motor, a vibration reducing spring, a base, and a foot. The function of each structure of the ultrasonic vibrating sieve is very unique and inseparable from the normal operation of the screen machine. The following is a detailed description of the various structures of the ultrasonic vibrating sieve:

Dust cover

In the process of material screening, ultrasonic vibrating sieve will inevitably generate dust, which will lead to dust flying. If there are more screening equipment at the production site, it will cause pollution to the working environment, and some dust will pass through the screen. Enter the lower screen frame, affecting product quality, dust cover to avoid powder flying and polluting the working environment.

Sieve frame

It is used to maintain the flatness of the screen and support the screen to ensure the normal screening operation of the ultrasonic vibrating sieve.

Screen

The material is sieved and classified to obtain the material with the qualified particle size. There are various choices of the material of the sieve, and the selection depends on the characteristics of the material to be sieved.

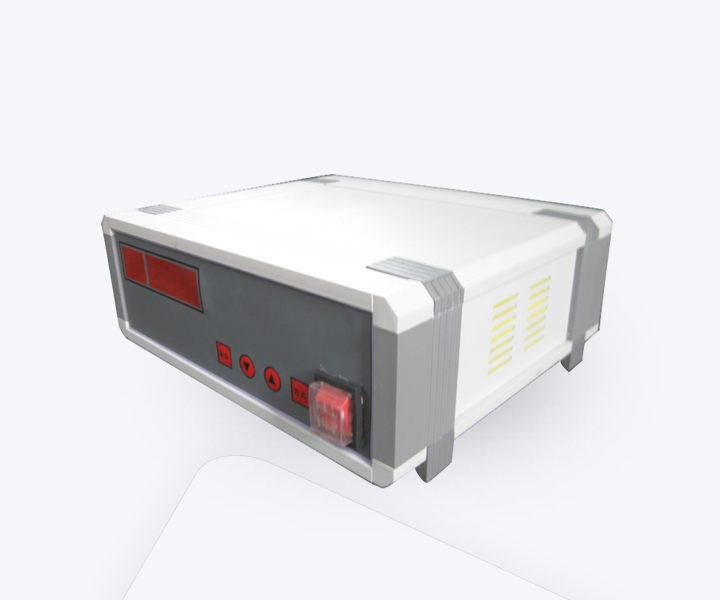

Ultrasonic device

It is the most important component of the ultrasonic vibrating sieve. It consists of an ultrasonic vibrating sieve power supply and an ultrasonic transducer. The ultrasonic vibrating sieve power supply converts the low-frequency current into a high-frequency current, thereby screening the material using high-frequency vibration. Ultrasonic transducers are one type of piezoelectric transducers. Piezoelectric transducers are transducers made using the positive and negative piezoelectric effects of piezoelectric materials. Transducers are devices that can perform energy conversion.

Damping spring

Reduce the vibration force generated by the vibrating sieve on the frame during the working process, and completely protect the long-term stability of the frame.

Vibration motor

It is the power source of the ultrasonic vibrating sieve, and the material moves on the screen surface by the action of the vibration motor.

Base

Supporting the entire sieve body to ensure the stability of the ultrasonic vibrating sieve during the screening process.

Ultrasonic vibrating sieve is the most ideal equipment to solve the screen clogging, because the ultrasonic vibrating sieve design adds a set of ultrasonic devices, which can convert various commonly used low frequency electric energy into high frequency electric energy of up to 38KHz, and then pass the ultrasonic transducer. Finally, a 38KHz mechanical vibration is obtained, so as to carry out efficient screening and cleaning work, which effectively solves the phenomenon of blockage caused by wood powder due to adhesion, high static electricity, easy agglomeration and the like.

Ultrasonic vibrating sieve can be said to be the best choice for screening fine materials. Wood powder ultrasonic vibrating sieve is suitable for mesh separation powder from 20 microns to 300 microns, especially for difficult-to-screen materials.

Strict sealing is required to screen fine powderto ensure that the fine powder does not fly during the screening process. Therefore, our fine powderultrasonic vibrating sieve is sealed with German imported glue, and sealed with silica gel or rubber. Sealing the pieces to solve the problem of fine powderscreening perfectly.

The above is a detailed introduction of the ultrasonic vibrating sieve for fine powder, I hope to help you!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.