electric flour sifter

electric flour sifter commercial electric flour sifter

commercial electric flour sifter portable lectric flour sifter

portable lectric flour sifter Mobile

Mobile electric flour sifter for flour

electric flour sifter for flour

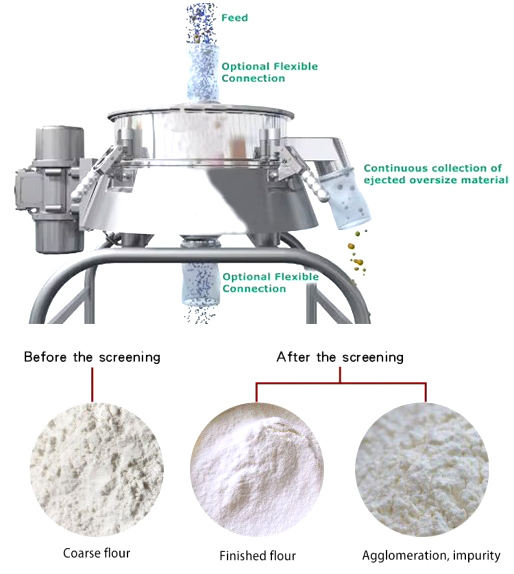

Used for impurity filtration and sieving of flour in large bakeries, food processing plants, etc.

![]()

![]()

Price:US$800.00 - US$4,500.00/Set

Consult now and enjoy a 10% discount

Function: Quickly remove impurities such as oversize, contaminants, etc. from flour

Mesh size: 140 mesh

Capacity: 2-30t/h

Power: :Single vibration source(0.18-1.5kw)、Double vibration source (2×0.12-2×0.15kw)_

Material: All stainless steel 304/316L

Application: Screens contaminants and lumps from a wide variety of flours of any type, including hard and soft wheat, semolina, cornmeal, and more.

Commitment:

Electric flour sifter is suitable for safety sifting, process sifting, inspection sifting of flour, mainly used for pre-package sifting, can be installed in artisan bakeries or large industrial flour mills, protects the quality of flour by eliminating caking and contamination Effective methods to ensure the safety, hygiene and quality of the final product.

The product is poured into the flour sifter to remove impurities and excessive contaminants before the flour passes through the sieve to the rest of the production line. The advantage of using this sieve is: since the inlet and outlet of the electric flour sifter are in the same vertical direction, That is to say, the direct discharge method is adopted, and the sifted flour is discharged directly through the screen at the discharge port below. The sieving is fast and the discharging is fast, so it is suitable for large output and coarse material screening, and the output per hour is high. up to 30 tons.

Electric Flour Sifter has a wide range of applications, mainly including the following aspects:

1. Bakeries and pastry shops: In professional bakeries and pastry shops, Electric Flour Sifter is one of the indispensable tools. It can help bakers and pastry chefs to quickly and accurately sift flour, ensure the uniformity and fineness of ingredients, and improve the quality of baked products.

2. Catering industry: In the catering industry, some high-end restaurants and bakeries also use Electric Flour Sifter to remove impurities or foreign matter that may be mixed in flour. It can also be used to sift cocoa powder, corn starch, etc., which expands its scope of use.

3. Food processing plants: In large-scale food processing plants, Electric Flour Sifter can be used to produce food in large quantities to improve production efficiency and product quality.

Reasons for sifting flour:

1. Flour will produce relatively large particles during processing or after being placed for a long time. If it is not sieved, it will cause uneven mixing, and agglomerates will remain in the batter, affecting the appearance and taste of the finished product.

2. Sieving can remove the agglomeration produced during the production and storage of flour, making the flour more fluffy and delicate.

3. After sifting, it can ensure the fineness and uniform size of the flour, which is good for mixing with eggs, butter, etc., and the taste of the finished product is more delicate and soft.

4. Mix a variety of powders and sieve them together to make them mix more evenly.

The electric flour sifter can effectively filter the lint, impurities, bugs and other foreign matter in the flour. The following Dahan Machinery will introduce the effect of the flour after use in detail:

1. Improved flour: Improve the physical structure of its powder particles, making the flour more fluffy (especially needed for puffed foods), uniform flour, and even distribution of gluten quality. Contact with water and other materials can effectively shorten the mixing time, and the dough gluten produced Uniformity and toughness.

2. Impurity removal: When the flour reaches a certain fineness, it can effectively remove the thread ends, drum skins, insect eggs, stones, metal impurities, etc. contained in the flour, effectively purify the flour, and improve the working efficiency of the food factory.

3. The overall design is very convenient, the flour can be poured directly into the sieve, and the dual vibration motors accelerate the operation, which effectively reduces the labor force and realizes mechanized operation.

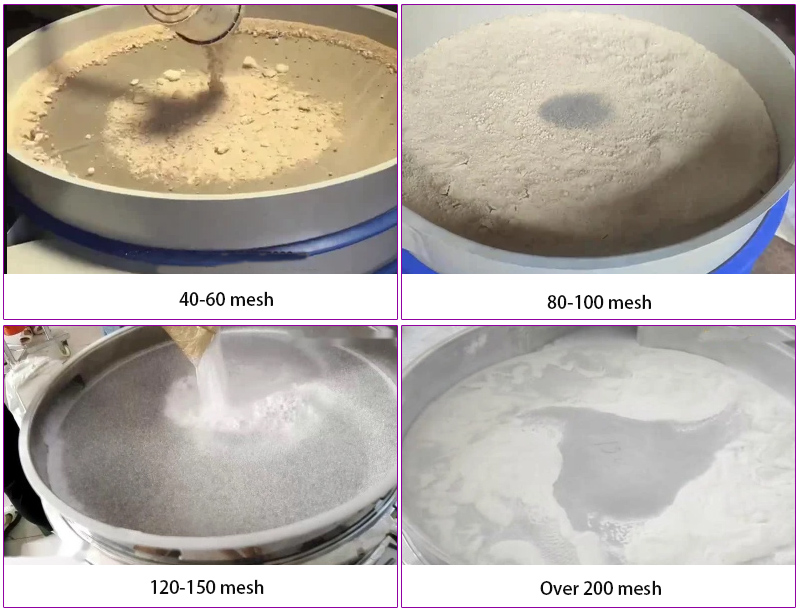

Electric flour sifter plays a vital role in the flour processing process. Through sieving, impurities in flour can be removed to ensure the purity and quality of flour. The selection of sieving mesh directly affects the final quality of flour. The mesh number of electric flour sifter is usually determined according to the type of flour, processing technology and final use. Common sieving mesh numbers and their applications are as follows:

1. 40-60 mesh: mainly used for sieving coarse powder to remove larger impurities, such as bran, stones, etc., used in the primary stage of flour processing, and some products that require coarse-grained flour, such as bread flour, biscuit flour, etc.

2. 80-100 mesh: used for sieving medium and fine powder, further removing fine impurities, improving the purity of flour, suitable for fine processing of various flour products, such as cake flour, dumpling flour, etc.

3. 120-150 mesh: used for sieving ultrafine powder to obtain high-purity and uniformly fine flour, used in some high-end flour products, such as pastry flour, baking flour, etc.

4. 200 mesh and above: used for screening of flour for special purposes, such as food and medicinal flour, which has extremely high purity requirements and is used in the production of food-grade high-purity flour.

The vibration force provided by the vibrating motor installed on both sides of the sieve machine drives the flour to move up and down on the sieve surface. Through the relative movement between the sieve surface and the flour, the flour moves and stratifies, and the materials with small particle size and high specific gravity contact the sieve surface. It becomes the under-sieve, and the sieved flour is directly discharged from the bottom of the electric flour sifter, which is mainly used in enterprises with high automation.

Improve product quality

Can be used to safely remove contaminants and agglomerates from flour, ensuring high product quality by eliminating potential contaminants.Can be installed in bakeries or food processing plants of all sizes.

High throughput

The inlet and outlet are designed in the same vertical direction, and the finished product under the sieve quickly passes through the screen, and the processing capacity is 2-5 times that of the general sieve.

SUS304 stainless steel

The components are made of 304 stainless steel, without sanitary dead corners, easy to clean and sterilize, and ensure hygiene and safety.

Closed system

The fully enclosed structure avoids flying powder, eliminates the problem of dust in the air, and manual interaction is pollution-free.

Easy to clean

The machine can be disassembled quickly without any tools and is easy to clean.It can avoid the contamination of the screening material.

Small footprint

The compact size meets industrial and commercial needs with minimal headroom and floor space, and can fit comfortably into any production line.

| Electric Flour Sifter | Manual Sifting | |

| Automation degree | Automation | Manual |

| Accuracy | Precision | May not be uniform |

| Work efficiency | Efficiency | Relatively low |

| Hygiene | Easy to clean, maintain hygiene | May have health risks |

| Scope of application | Mass production, industrial occasions | Small batch, home use |

There are some obvious differences between the Electric Flour Sifter and manual sifting in the flour sifting process, mainly including the following points:

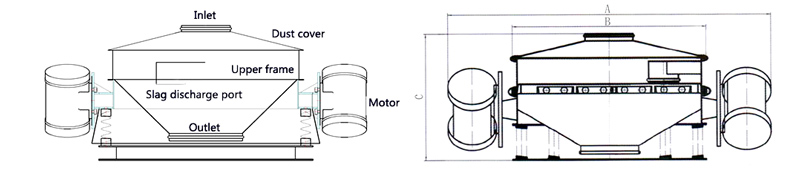

| Model | Power(kw) | RMP(r/min) | Sieve diameter(mm) | A | B | C |

| ZPS-600 | 0.18 | 1460(960) | 520 | 1070 | 600 | 502 |

| ZPS-800 | 0.25 | 720 | 1390 | 800 | 525 | |

| ZPS-1000 | 0.37 | 890 | 1566 | 970 | 543 | |

| ZPS-1200 | 0.55 | 1090 | 1875 | 1170 | 814 | |

| ZPS-1500 | 0.75 | 1390 | 2226 | 1470 | 875 |

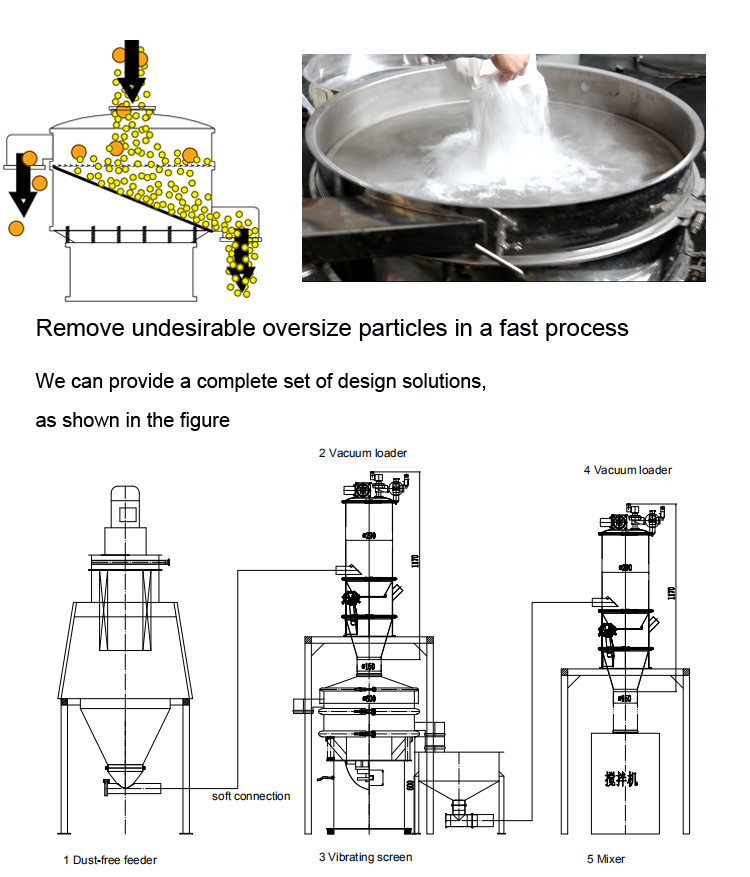

The electric flour sifter can be used with the feeding station (dust-free feeding station) for unloading and checking small or extra-large bags of flour to avoid dust problems in sieving. The following table shows you the difference between the new and old processes:

| Project | Describe | Can Save |

| Artificial | The new process can save 6 people:The new process only needs: 1 person for feeding materials, 1 person for mixing noodles, saving 1 person for delivering noodles, 4 people for operators, and 1 person for batching. | Save $40,000 per year in labor costs: (solved the problem of difficult recruitment) According to the per capita 685 US dollars / month, 2 people * 685 US dollars * December = 16440 US dollars. |

| Environmental Friendly | The new process seals and connects each equipment with pipes, and the whole process is dust-free, in line with the requirements of environmental protection class A, and production will not be stopped throughout the year. The dust of the old process is flying, and there is a hidden danger of dust explosion. |

More than 2.5 million losses can be avoided: For example: the old process needs to stop production when the red and orange warnings are issued, and the loss is 2.5 million if the production is stopped for 50 days; The dust explosion hazard is not calculated. |

| Materials | Way of working | Screen (mesh) |

Capacity (kg/hour) |

Model |

| Milk powder | dry | 16.2 | 2000 | DH-1200-1S |

| Starch | dry | 80 | 1200 | DH-2000-2S |

| Wheat starch | wet | 200 | 3200 | DH-2000-1S |

| Flour | dry | 24 | 1500 | DH-1000-1S |

Electric flour sifter ensures the high quality of your product by eliminating potential contaminants and can be installed under bulk silos for safe sifting of flour or pneumatically conveyed from tanker or railcar receiving operations for post-delivery inspection feed. Russell sieves can also be installed in bakeries and food processing plants of all sizes. Dahan Machinery is specifically designed to enable operators to unload and inspect small or oversized bags of flour in one simple dust-free operation.

Xinxiang Dahan Vibration Machinery Co., Ltd. was established in 2008. It mainly designs and manufactures vibrating screens, screeners, filters and other screening equipment. It is designed for the global market. All machinery is supplied to more than 80 countries for use in the entire processing industry.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.