Suitable for dust-free and airtight feeding, unpacking, unloading and screening of powders in chemical, pharmaceutical, food and other industries

![]()

![]()

![]()

Price:$797.00-$5,400.00/Set

Consult now and enjoy a 10% discount

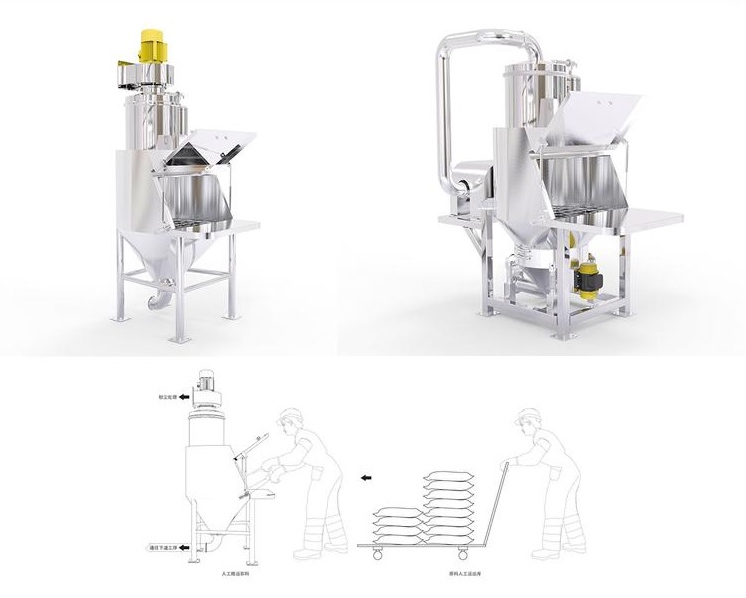

Function: Bulk material ton bag dust free dump station

Material: Stainless steel 304,316L,or Carbon Steel

Feeding specifications: 0-50kg/bag

Feeding method: single feeding port/double feeding port

Wind pressure: 1217-1641Pa Air volume: 1550-997m³/h Power: 2*0.25KW

Optional equipment:

Application: Unpacking, feeding, screening and unloading of small bags of materials in food, pharmaceutical, chemical and metallurgical industries, especially suitable for manual feeding and pre-screening of powder materials

Commitment:

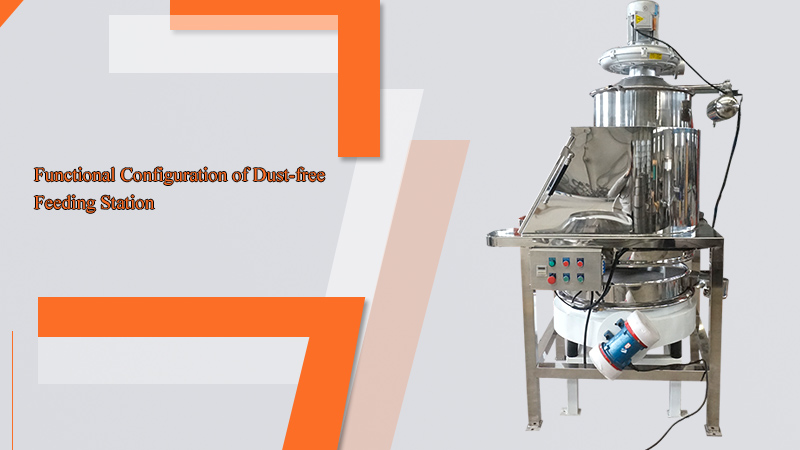

Dust-free feeding station is also called ton bag dump station, bag tipping platform, bag dumper station, bag dump screener system, sack tip station, low profile bag dump, sanitary bag dump with integral dust collector etc, suitable for food, medicine, chemical industry Unpacking, feeding, screening and conveying of manual and bagged materials in other industries.

Dust-free feeding station is composed of manual feeding platform, feeding bin, vibrating sieve, dust collection system, air bag dust removal system, etc. It adopts dust removal and filtering feeding operation platform, which can realize no dust overflow during the manual feeding process, and one device can be opened Pour 50 kg, 25 kg, 15 kg bags, greatly reducing the labor intensity of workers.

Dust-free feeding station is mainly to manually unpack the bag and introduce the material into the dust-free feeding station, and use the negative pressure dust collection device to automatically suck the dust particles generated during the discharging process, so as to avoid the dust flying in the traditional feeding method and protect it more effectively. operator's health. The video below is the dust removal test of the dust-free feeding station and the traditional feeding method:

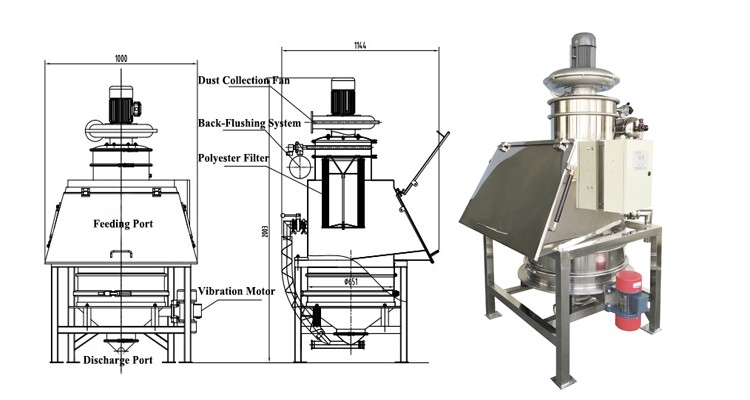

When the material is manually or automatically conveyed to the dust-free feeding station through the roller table or the lifting device, the dust-laden gas enters the dust removal system under the action of the induced draft fan in the feeding station, the dust and the air flow countercurrently, the filter element, and the air passes through the filter element It enters the dust bag and is discharged from the outlet of the induced draft fan. The fine dust is trapped in the filter element and cannot be discharged with the gas. The dust-free feeding station can complete the bag opening, feeding, back blowing and dust collection, so as to achieve the effect of gas and dust separation.

The feeding material can pass through the vibrating sieve at the bottom of the dust-free feeding station to intercept bulk materials and foreign objects to ensure that the particles that meet the requirements are discharged. The fed material can also be transferred to the next process through the vacuum feeder. Screening, no dust flying, especially suitable for feeding, screening and conveying of materials with poor fluidity.

Dust-free feeding

The automatic dust collection system can well inhale and discharge dust, prevent the material from generating dust during unpacking and feeding, and improve the working environment.

Sealing structure

The overall airtight, no leakage, no cross-contamination, can be directly installed in the clean workshop to ensure a clean and relaxed working environment for workers.

Various specifications of bag opening stations

One equipment can dump 50kg, 25kg, 15kg bags, which can meet different processing requirements.

Materials can be reused

The principle of backflushing is adopted to minimize the loss of products and realize the reuse of materials.

Various materials

Dust-free feeding station can choose various materials according to the different requirements of customers: stainless steel (SS304, SS304L, SS316, SS316L), carbon steel, etc., but stainless steel is generally used for equipment.

Easy to adjust

The overall structure, overall height, and screening device can be designed and adjusted according to the actual site layout of the user, and can also be equipped with vibrating screen, iron remover, vacuum feeder and other equipment for comprehensive use.

| Model | Dust removal fan power (KW) |

Motor power (KW) |

Screen mesh | Dust filter specifications |

| TLZ-1 | 0.75 | 0.05 | 400 mesh or customized | Imported 0.5μm polyester film*1 |

| TLZ-2 | 1.1 | 0.07 | Imported 0.5μm polyester film*2 | |

| TLZ-3 | 1.5 | 0.12 | Imported 0.5μm polyester film*4 |

Dust-free feeding station is divided into upper and lower main parts, the upper part is for dust collection, and the lower part is for raw material screening or raw material conveying. The two are connected by a soft connection in the middle, and the upper fabric silo is connected to the on-site material conveying equipment. After the material enters the silo, it directly goes down to the screen surface through the soft connection for screening treatment. There is no dust flying and no material loss in the whole process .

Bag dumping station inlet: it can add screen to prevent debris go in hopper in case.

Dust collection filter element: high quality imported filter element,It can quickly and effectively remove dust and prevent environmental pollution.

Filter cleaning device: it can clean the filter element automatically, improve work efficiency. Explosion-proof motor can be used according to customer requirements, suitable for different powder materials.

Electric control box: easy to operate and safe.

Universal wheel: easy to move to different places.

Feeding specification: 0~50KG/bag

Feeding method: single feeding port/double feeding port

Material lifting: manual / lifting bucket / lift truck / forklift

Arch breaking type: pneumatic high frequency vibration / activated hopper vibration

Backflush Type: Pneumatic Pulse

Optional equipment: iron remover / single-layer vibrating screen / coarse crusher / bag collecting device / weighing and conveying

Dust-free feeding station is used to unpack and feed dry powder and granular materials such as plastic resin, cement and food additives in small bags of 25KG or 50KG in plastic, rubber, food, medicine, chemical and other fields.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.