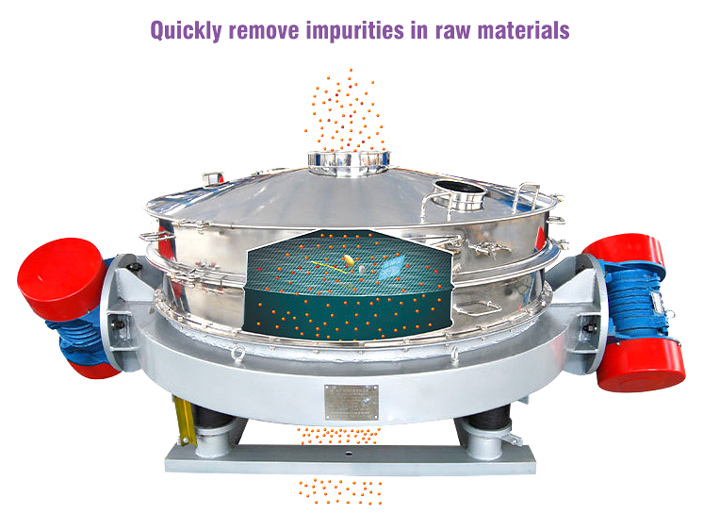

Direct discharge sifter is for rough inspection, screening and impurity removal of powders and granules. It is very suitable for screening incoming ingredients and final production inspection of finished products. The working principle of direct discharge sifter is introduced below.

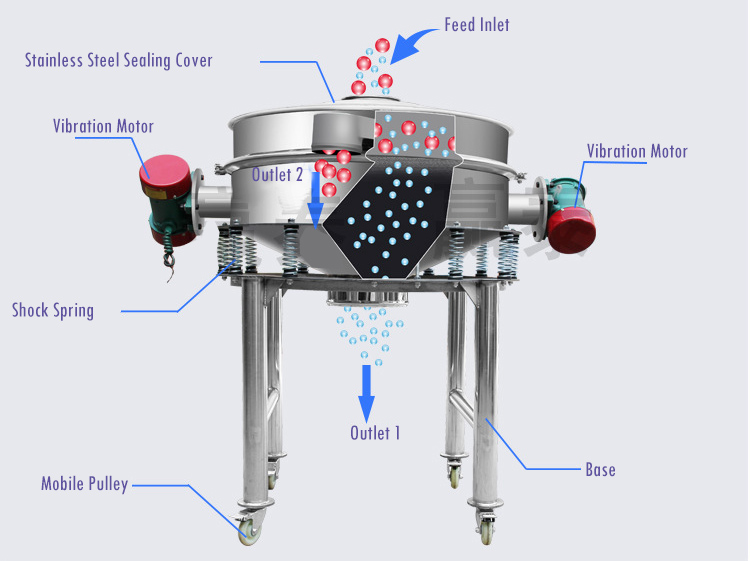

There are two vertically installed motors on each side of the direct discharge sifter. The material enters the direct discharge sifter through the feeding port. According to different material screening requirements, the material passes through the screen layers of different mesh screens, and the material larger than the screen aperture stays in the direct discharge sifter. The screen surface is discharged from the upper discharge port, and the material smaller than the screen aperture is quickly sieved and discharged from the lower discharge port.

It is precisely because of the unique structure and separation of direct discharge sifter that direct discharge sifter has the following advantages

1. The inlet and outlet are designed in the same vertical direction, and the large flow outlet at the bottom enables the material to be discharged directly, the discharge speed is fast, and the output is 2-5 times that of the ordinary round screen.

2. It can be used directly in series in the pipeline to remove foreign matter and impurities in the pipeline without manual operation and avoid secondary pollution to materials.

3. Since the direct discharge sifter motor is designed outside the equipment, the height of the equipment is reduced and the space is effectively used.

The above is an introduction to the working principle of direct discharge sifter. Direct discharge sifter, as a coarse sieving equipment in fine sieving equipment, can screen and filter powders and granules within 200 meshes, and is widely used in washing powder, chemical fertilizer, medicinal powder, salt, Monosodium glutamate, seasonings, milk powder, starch, flour, rice flour, carbon powder, graphite powder, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.