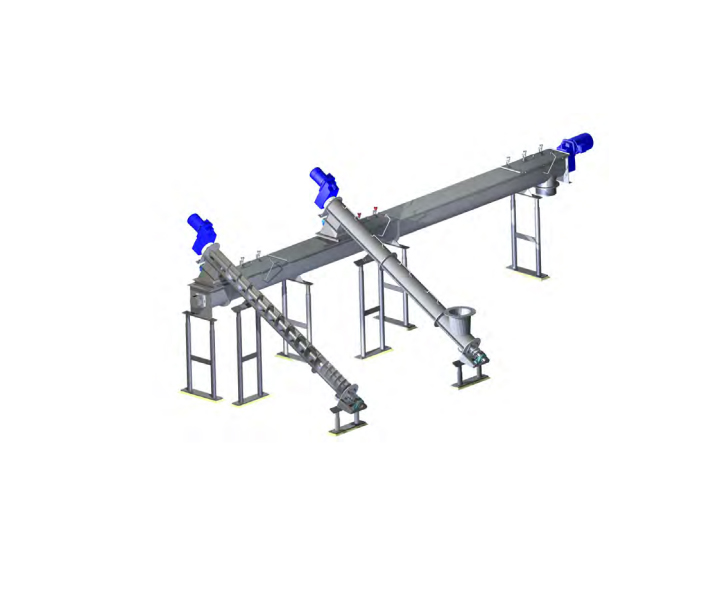

For conveying bulk materials from almost any position (vertical, horizontal or inclined)

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 100-1250mm

Delivery capacity: 458 cubic meters per hour

Conveying length: 2-70 meters

Installation angle: 0-90 degrees

Blade thickness: 2~6mm,

Speed: 20~150/min

Material: carbon steel, stainless steel, plastic

Application: As an effective means of conveying semi-solid materials including food waste, wood chips, aggregates, grain, animal feed, boiler ash, meat and bone meal, municipal solid waste and many others.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

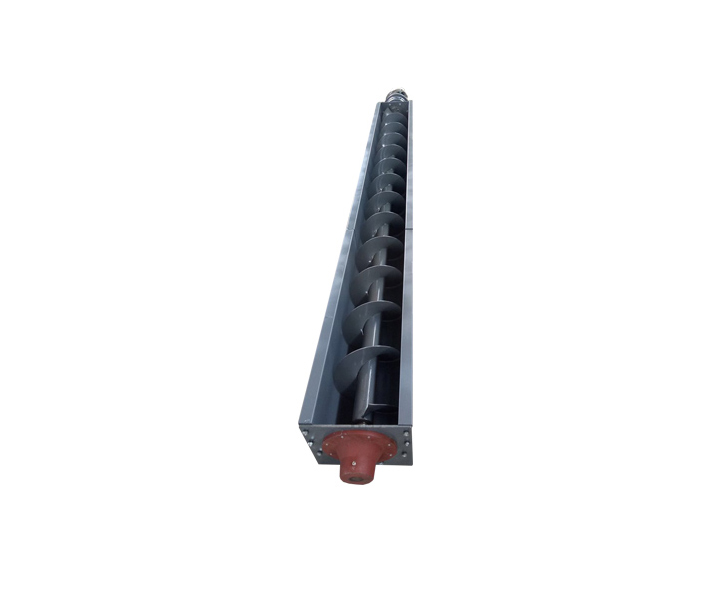

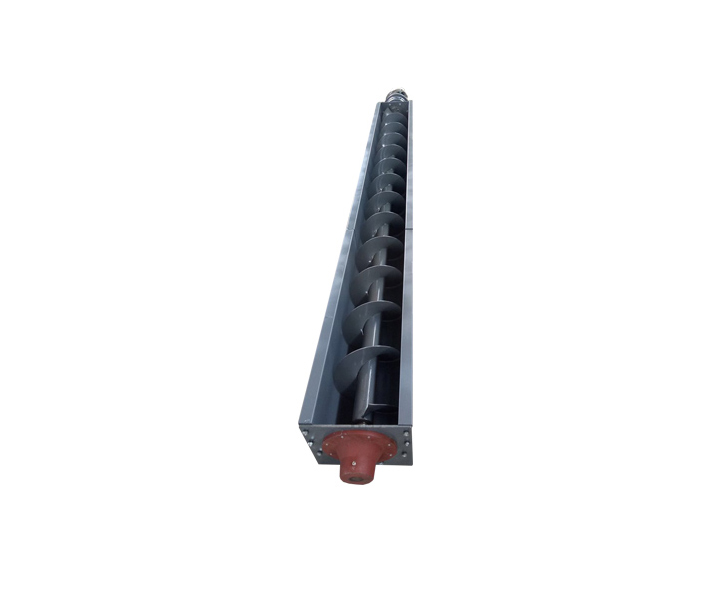

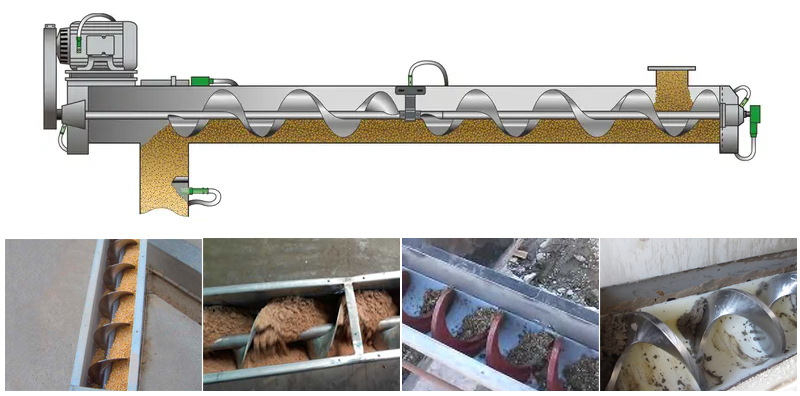

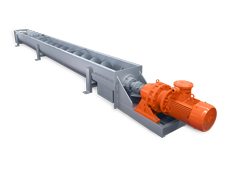

Worm conveyor, also called worm screw conveyor, is a mechanical device used to transport a variety of materials, including solids, powders, and granular matter. It consists of a spiral blade (called a worm) contained in a tube or trough. The rotation of the worm in the tube moves the material along the conveyor.

Worm conveyors are commonly used to transport granular or powdered materials such as biomass, coal, gravel, slag, sand, gypsum, coal powder, ash, alternative fuels, and high-temperature materials. They are efficient, reliable, and can be designed to meet specific material handling requirements. The main materials of worm conveyors include stainless steel, carbon steel, and plastic. The screw diameter is usually between 113mm and 600mm. The conveying angle generally ranges from 0 to 90 degrees. Special designs can include heating/cooling functions, anti-stick coatings, and adjustable speed functions to meet different material conveying needs.

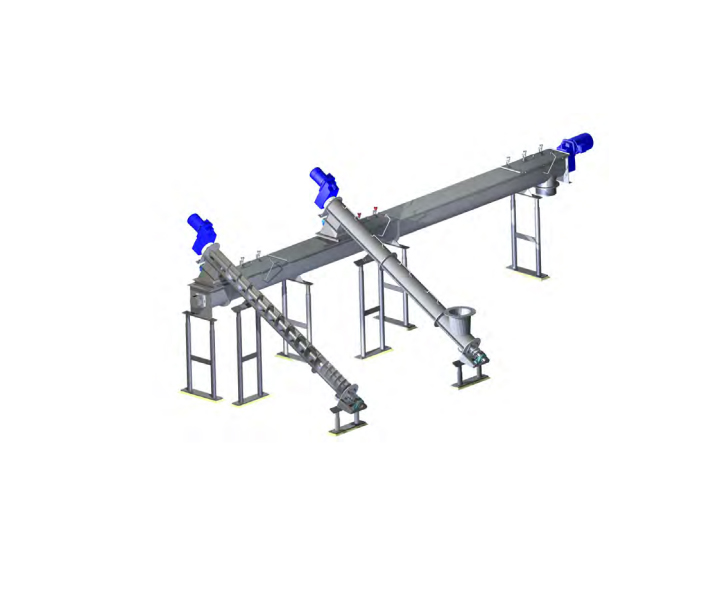

There are several types of worm conveyors, each designed to suit specific applications and materials. Here are some of the most common types of worm conveyors:

Used to transfer bulk materials from one part of the process to another

Operation in a position slightly above horizontal

Provides a clog-free conveying surface for difficult-to-convey materials

The most efficient and cost-effective way to lift a wide variety of bulk materials

The principle behind a worm conveyor, also known as a screw conveyor, relies on two key factors:

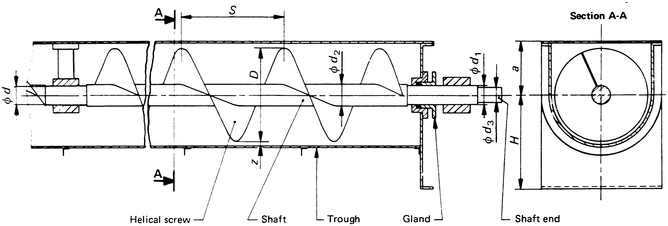

1.Screw Rotation: The conveyor has a helical screw blade (flighting) fixed on a central shaft. This shaft rotates inside a trough or tube.

2.Friction and Material Movement: As the shaft rotates, the screw blade pushes the material along the bottom of the trough. The material doesn't rotate with the screw itself. Here's why:

Friction between the material and the trough wall: This friction creates resistance that prevents the material from simply spinning with the screw.

Gravity: For most bulk materials, gravity pulls them down towards the trough bottom. This keeps them engaged with the screw for continuous movement.

Efficient transportation

Provides a continuous and controlled flow of material along the conveyor, which increases the efficiency of material handling and transportation.

Gentle handling

The material can be handled gently, which helps preserve its quality and value and reduces the risk of damage or breakage.

Versatility

A wide variety of materials can be handled, including powders, granules and other types of granules, making it suitable for a variety of industries.

Customizable Design

Can be customized to suit different applications and materials, with different sizes, shapes and materials of construction available.

Low maintenance cost

Requires minimal maintenance and can run continuously, reducing downtime and maintenance costs.

Safe operation

Provides a safe, enclosed method of transporting materials that reduces the risk of spills, dust emissions, and other hazards associated with other modes of transport.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

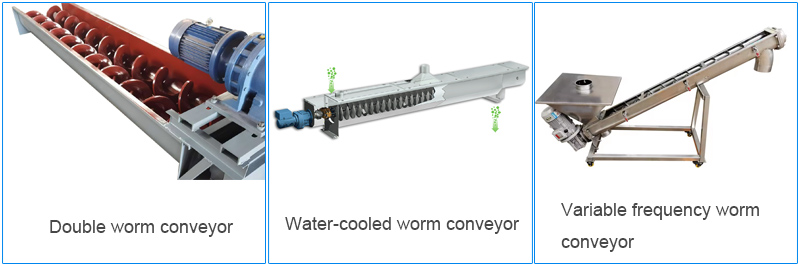

Worm conveyors can be classified and customized according to different characteristics and application requirements. Here are several common worm conveyor types:

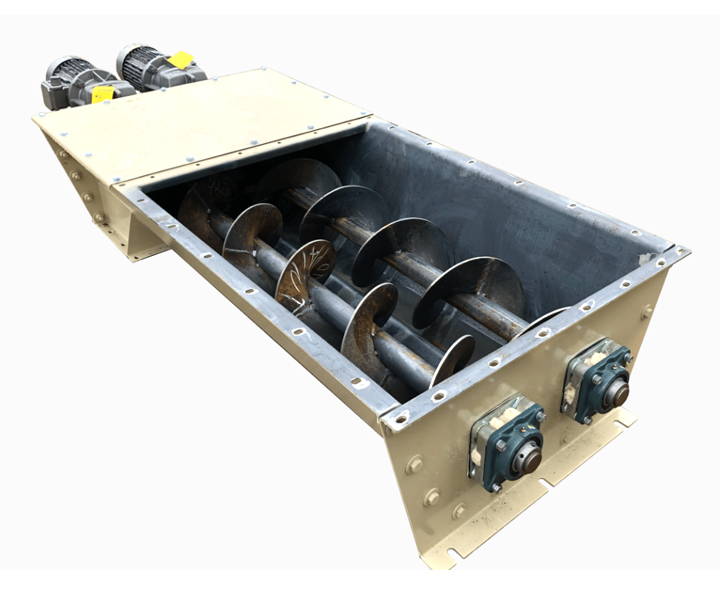

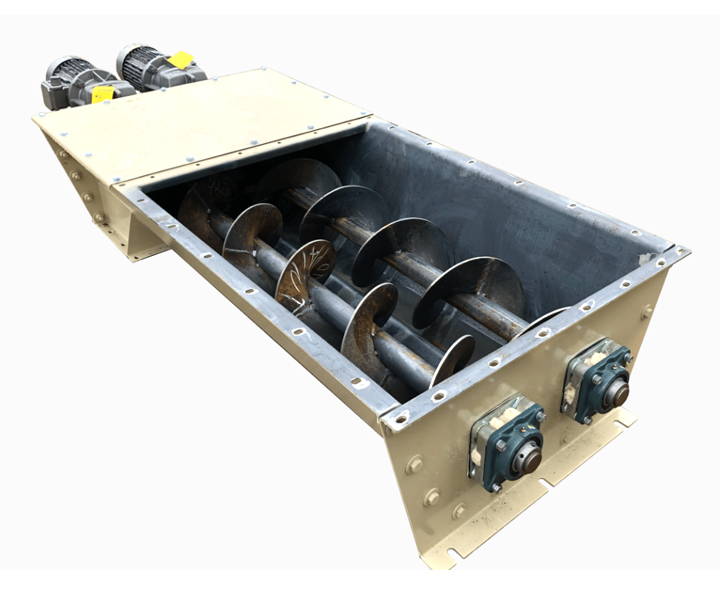

Double worm conveyor: Double worm conveyor refers to the installation of two spiral blades in a pipe, which work in opposite directions of rotation. This design can achieve higher conveying capacity and more uniform material mixing, and is suitable for applications requiring larger throughput and mixing effects.

Water-cooled worm conveyor: Water-cooled worm conveyor is a conveyor with cooling water pipes installed inside the spiral blades and conveying pipes. It is usually used to handle high-temperature materials or when the temperature of the materials needs to be reduced. The circulating cooling water can effectively reduce the material temperature and prevent the deterioration or damage of heat-sensitive materials.

Variable frequency worm conveyor: Variable frequency worm conveyor is a type that uses a frequency converter to control the speed and delivery volume of the worm conveyor. By adjusting the speed, precise control and adjustment of the conveying volume can be achieved to adapt to different materials and process requirements. Variable frequency worm conveyors are often used in applications that require flexible adjustment of conveying volume, such as batching, weighing and mixing processes.

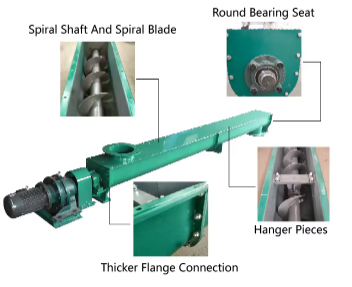

Worm conveyors, also known as screw conveyors, consist of several key parts that work together to efficiently move material. Here are the main components:

Trough: The trough is a long, U-shaped channel that holds the material being conveyed. It can be made from various materials like steel, stainless steel, or even plastics depending on the application and the material being handled.

Screw (Flighting): This is the helical shaft with a wound ribbon around it, like a giant screw. The rotation of the screw creates a pushing action that moves the material forward through the trough. The flighting can be made in different designs, depending on the material being conveyed.

Shaft: The central solid rod that runs through the center of the trough and supports the screw. It transmits the torque from the motor to rotate the screw.

Hanger Bearings: These bearings support the screw shaft along the length of the trough. They are typically mounted on brackets that are welded or bolted to the trough exterior.

Drive System: This is the motor and gearbox assembly that provides the power to rotate the screw shaft. The motor selection will depend on the capacity and material the conveyor needs to handle.

Inlet and Outlet: The inlet is the opening at one end of the trough where the material enters the conveyor. The outlet is the opening at the other end where the material exits the conveyor. These openings can be flanged for easy connection to other equipment.

1.Material properties:

Particle size and shape: The particle size determines the size of the spiral blade gap. Variable pitch spirals can be used to handle irregular shaped materials.

Density: Adjust the spiral diameter to adapt to materials of different densities.

Viscosity: Choose a variable pitch spiral or add agitator blades to improve the fluidity of viscous materials.

Abrasiveness and corrosion: Use wear-resistant or corrosion-resistant materials, such as alloy steel and stainless steel, to deal with abrasive or corrosive materials.

Temperature: Use high temperature resistant materials, such as high temperature alloy steel, to handle high temperature materials.

2.Material selection:

Low carbon steel: Suitable for general conveying applications.

Stainless steel (304 and 316 grades): Has corrosion and wear resistance.

3.Other influencing factors:

Conveying capacity: Select the spiral diameter according to needs.

Conveying distance: For long-distance conveying, consider multi-section spirals or support designs.

Conveying height: Adjust the angle of the spiral blades to ensure stable vertical conveying.

Working environment: Consider environmental factors to select appropriate sealing and protection measures.

Worm conveyors provide versatile and efficient solutions for material handling in various industries. The specific application depends on the type of material being moved and the application requirements:

Food Processing: Typically used in the food processing industry for conveying materials such as flour, sugar, grains and other food products.

Agriculture: Used in agriculture to transport materials such as seeds, fertilizers and animal feed.

Chemical Processing: Used in the chemical processing industry to convey materials such as powders, granules, and other chemicals.

Manufacturing: Used in manufacturing to move materials such as plastics, rubber, and other materials used in the production process.

Mining industry: used to transport materials such as coal, ore and other minerals.

Waste Management: Used to move materials such as trash, recycled materials and other waste products.

Water Treatment: Used to transport materials such as sludge, sediment and other waste.

Dahan worm conveyor manufacturers are aimed at the long-distance and high-level conveying and lifting of powdery, granular, blocky and other materials, and can be configured on various production lines, such as: mixing stations, flour mills, powdered food packaging factories and other industries.

Provide free test machine service to ensure that the product can achieve the delivery effect that users want, and also provide high-definition material test machine video. If the test machine video you want is not available in our manufacturer, you can also mail the material to our factory The postage can be reimbursed and the video will be sent to you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.