Can be used to cool almost any bulk material and can cool your product from 450 degrees Celsius to below 50 degrees Celsius

![]()

![]()

![]()

Price:$550.00 - $35,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 300-500mm

Material temperature: Input: 450℃ Output: Below 100℃

Water temperature: Input: 40℃ Output: 55℃

Cooling water volume flow/capacity: 71.3m 3 /h

Throughput: 3-10m³/h

Conveying length: 7 meters

Application: usable for bed-ashes, flue-dust, sewage-slurries, cements, salts, plastics, pyrolysis residues, cyanideor pastures in every kind of condition.

Commitment:

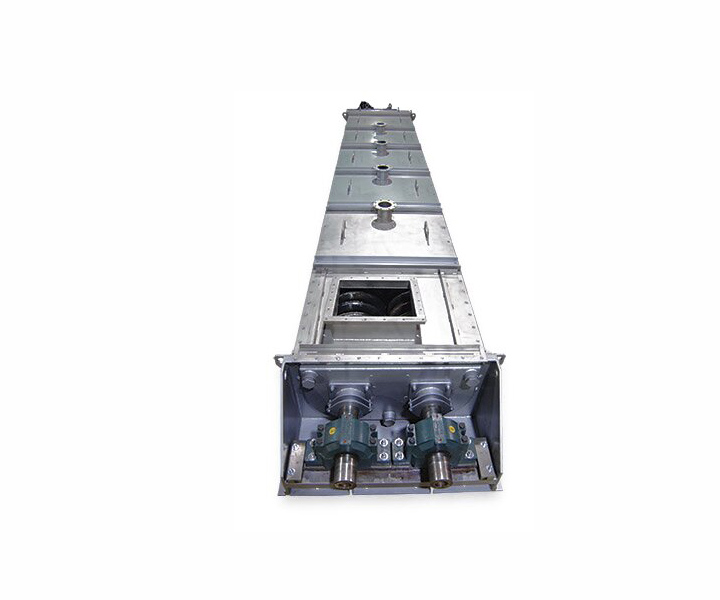

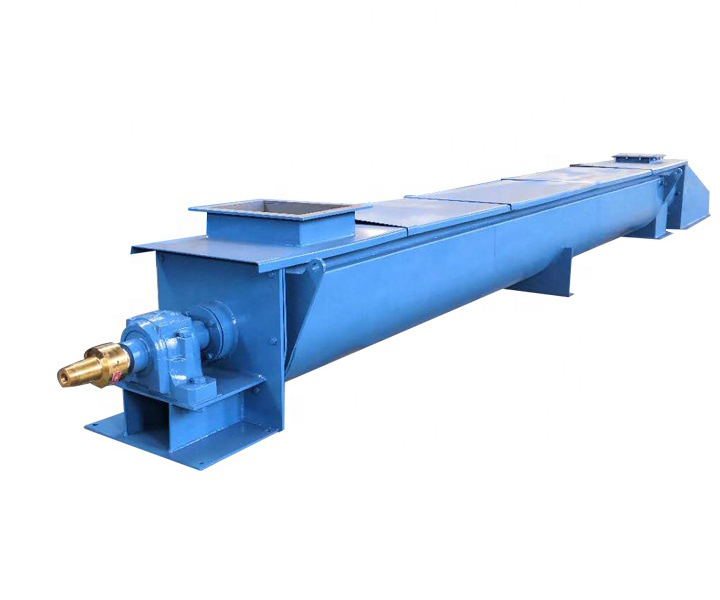

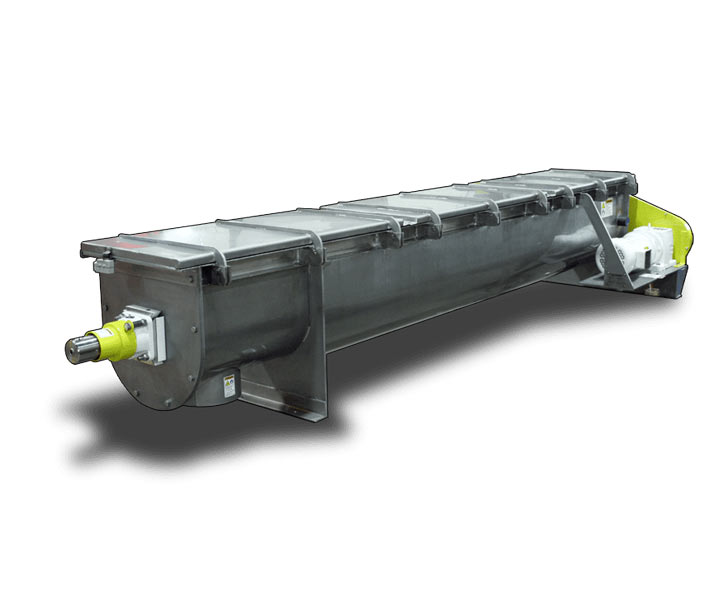

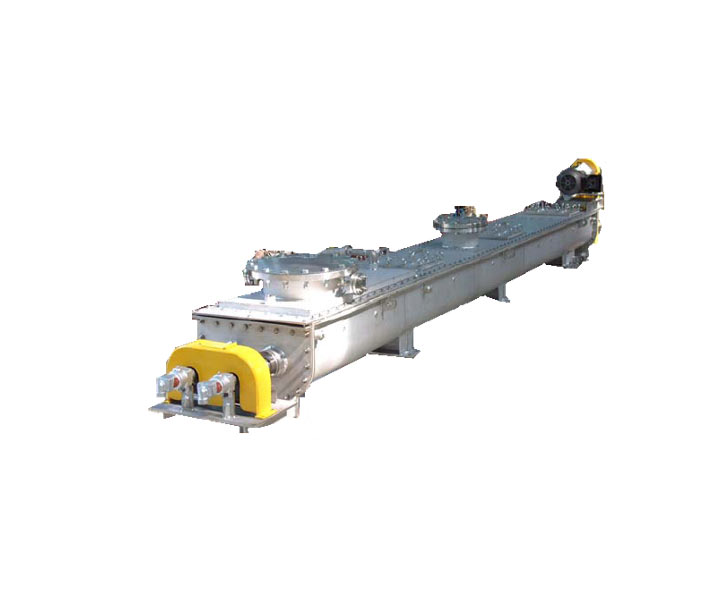

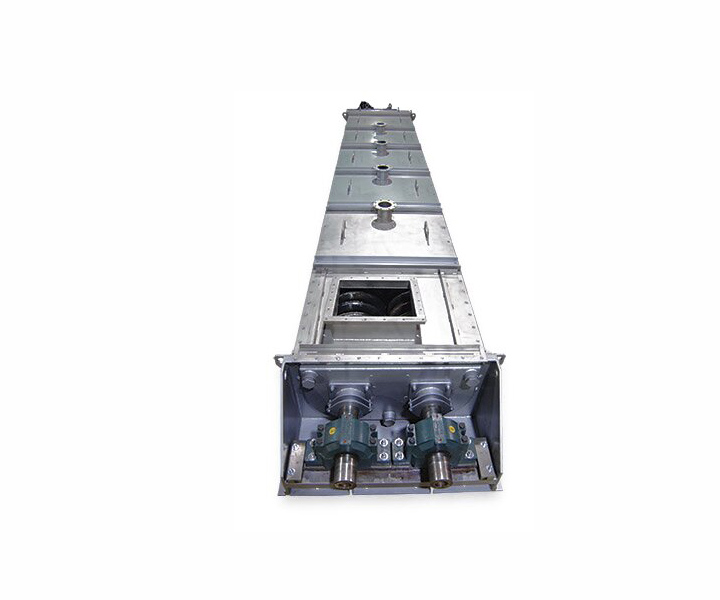

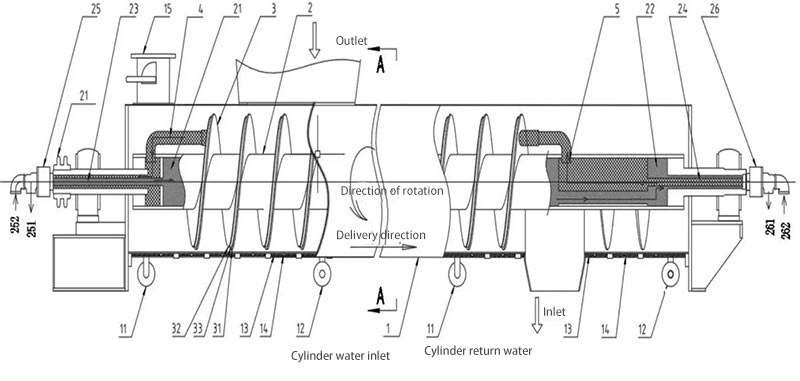

Cooling screw conveyor is specially used for conveying high temperature products after burning or high temperature products, Heat indirectly transfers from the product by introducing a heat transfer medium such as cool water through a special trough jacket and/ or through the pipe and hollow flights of the screw processor. Achieving the specified exit temperature of the product is accomplished by calculating the surface area of the screw processor and designing the system flow to match the heat load requirements of the application. The temperature of the conveyed material entering the screw inlet is 450 degrees, When discharging, the temperature should drop below 100 degrees, which is suitable for conveying high-temperature fly ash, cinder, rubber powder, carbon black and other materials.

Cooling screw conveyor is a conveying equipment that integrates cooling and conveying. It is equipped with a water cooling system. The cooling water flows from the empty pipe at the inlet end through the spiral plate cavity and then flows out from the empty pipe at the initial stage to form a cooling water channel. The material has a good cooling effect during the conveying process. The effluent does not circulate in the spiral and is not easy to structure, which enhances the production efficiency.

1. Circulating water cooling direction: enter from the screw outlet and flow out from the screw inlet. , Circulating water cooling: The outer cylinder of the machine is equipped with a jacket of a certain length, and the jacket is equipped with cooling circulating water. After the material enters the cylinder, it rotates and moves, and the material continuously contacts the cold water jacket. Cooling effect.

2. Cooling method: internal cooling (screw shaft), external cooling (jacket), internal and external dual cooling: internal cooling refers to the rotating shaft, which is hollow and can be filled with cold water, and external cooling refers to the jacket, which can cover a large area Cool down the material to the greatest extent.

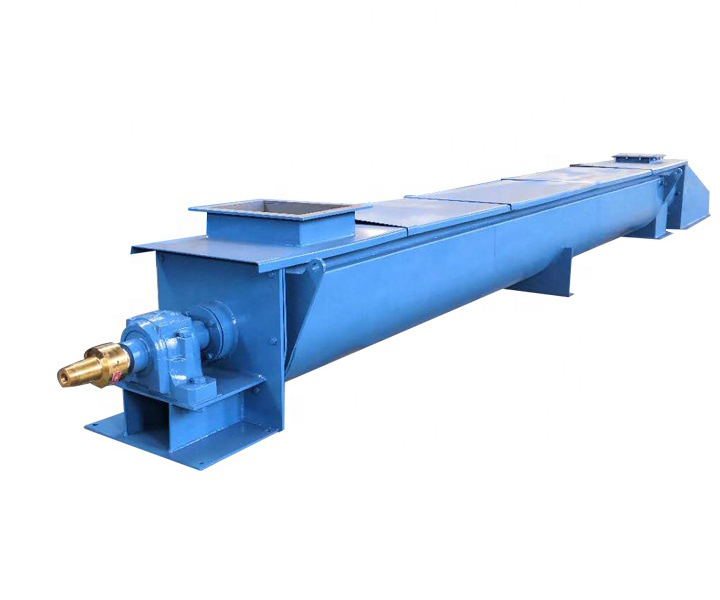

3. The length of the barrel is the key to cooling down: the materials conveyed by the water-cooled screw conveyor are generally freshly burned materials or materials with high temperature, so it takes a certain amount of time during the transportation process. The longer the barrel length, the better the cooling effect.

Material 304 atomizing nozzles: At the outlet of the conveying screw, install on the spiral blades, and then install one every 200mm at the inlet of the conveying screw, a total of three atomizing nozzles are installed, and the water volume can be adjusted individually, and can also be easily disassembled separately , easy to clean its nozzle.

The material entering the cooling screw conveyor passes through the circulating water in the jacket of the conveyor, and in the process of heat exchange, the temperature of the material is lowered during the operation of the equipment. However, due to the temperature, some materials only need one conveyor. It can cool down, and some materials will need 2-3 sets of equipment for direct cooling if the temperature is too high.

Material cooling

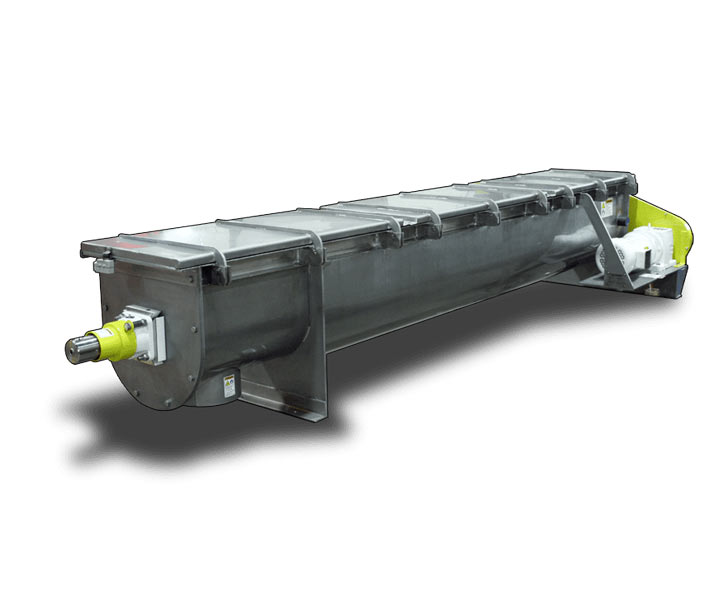

The maximum temperature of the feeding material can reach 720 degrees Celsius, and the cooling water flowing in the spacer and the central spiral tube can make the temperature of the material discharged as low as 50 degrees Celsius. It is a conveying equipment that integrates cooling and conveying.

Good cooling effect

In the process of conveying, the cooling effect of the material is better than that of uniform cooling. In addition, the water developed by our company does not circulate in the spiral without scaling, thus solving the maintenance time and enhancing the production efficiency.

Efficient delivery

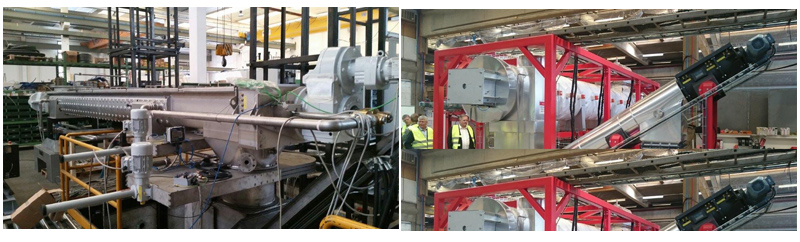

It can be fully enclosed for transportation to eliminate dust pollution, or open for transportation. The single-machine conveying distance can reach 20 meters, and the multi-machine soft connection can be extended as needed.

Long lasting

The water-cooled shaft is a hollow structure, made of high-quality carbon steel, and the water-cooled tube is used for the circulating cooling of the water-cooled shaft to improve the use environment of the shaft and increase the service life of the shaft.

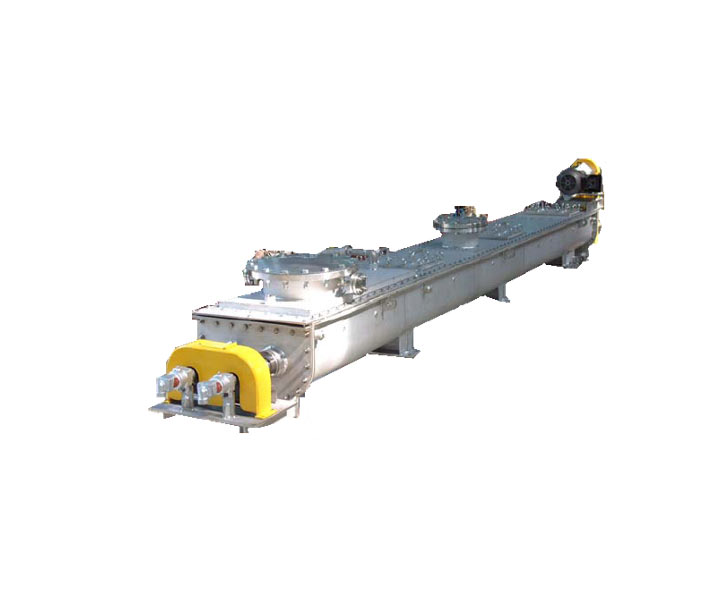

Our cooling screw conveyors introduce heat transfer medium, such as cold water, hot oil or steam, through special grooved jackets or the pipes and hollow threads of the screw conveyor, and indirectly transfer heat to or from the product, by calculating the surface area of the auger And design the system flow to match the heat load requirements of the application to achieve the specified outlet temperature of the product.

Common applications:

Fly ash cooling coal-fired power plant boilers

Heating lime for asphalt shingle operations

maintain a specific temperature for food

Cooling of drill cuttings from rotary dryers

| Spiral diameter(mm) | 300 | 400 | 500 |

| Pitch(mm) | 300 | 400 | 500 |

| Rotating speed(r/min) | 6 | 7 | 8 |

| Throughput(m3/h) | 3 | 5 | 10 |

| Motor Power(Kw) | 3 | 3-4 | 4 |

| Conveying distance(m) | <7 | <7 | <7 |

| Material temperature(℃) | <800 | <800 | <800 |

| Material proportion(%) | ≈0.8 | ≈0.8 | ≈0.8 |

| Blade material | SU304 | SU304 | SU304 |

| Water pressure(MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| import and export | DN40 | DN40-50 | DN40-50 |

(1) Material cooling range: the temperature difference between the maximum temperature and the minimum temperature, so as to design the cooling series, and the length of a single-stage cooling generally does not exceed 7 meters.

(2) The temperature of the cooling source: the initial temperature of the cooling source temperature of 5°C and 30°C has different effects on the same equipment design, so it is necessary to prepare the necessary data before designing the scheme, so as to design a reasonable water cooling scheme for you.

(3) Characteristics of materials: Different materials have different heat dissipation properties. Before ordering equipment, accurate materials must be provided so that our company can perform calculus simulation to ensure the cooling effect.

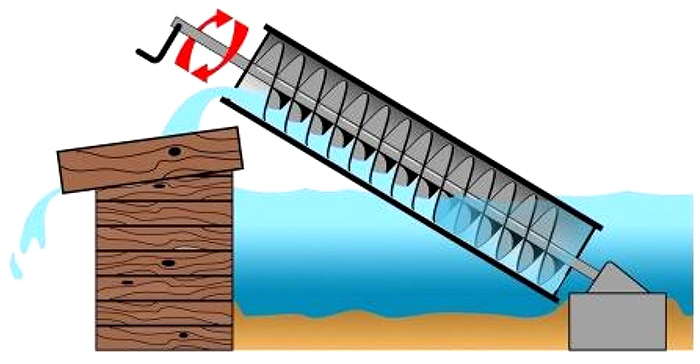

(4) Equipment installation space location: it is good for low-temperature cooling applications, and occasions with a large cooling range require a larger area. To be arranged, it can be arranged horizontally or vertically, or it can be arranged obliquely. to meet location requirements.

(5) On-site power source: In the design of water-cooled cooling, the ultra-high temperature cooling system is not limited to the form and structure of water-cooled cooling. The design scheme will also design composite process structures such as air-cooling and air-cooling.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.