Worm screw conveyor is a kind of conveying equipment with compact structure, stable transmission and strong load-bearing capacity. It is widely used in food, medicine, chemical industry and other industries. Generally speaking, the price of a worm gear screw conveyor is affected by many factors, ranging from a few thousand yuan to tens of thousands of yuan. The following is an introduction to the price of a worm gear screw conveyor.

1.Specifications and models: Worm screw conveyors of different specifications and models have different conveying capacities and sizes, and the prices will vary. Generally speaking, the price of equipment with greater conveying capacity and size will increase accordingly.

2.Material and quality: The material quality of the worm screw conveyor directly affects the durability and service life of the equipment. Equipment made from high-quality materials is usually more expensive, but can reduce maintenance costs over the long term.

3.Manufacturer: Worm screw conveyors from different manufacturers differ in quality, technology, after-sales service, etc., and the prices will also vary. Equipment from well-known brands may cost slightly more.

4.Additional functions and customization requirements: If additional functions or customized worm screw conveyors are required, the price will increase accordingly.

5.Market supply and demand: When market demand is strong, the price of worm screw conveyor may rise; conversely, when market competition is fierce, the price may fall.

6.Transportation and installation costs: Worm screw conveyors usually require transportation and installation, and these additional costs will also have an impact on the final price.

7.After-sales service: The quality and guarantee of after-sales service of the equipment will also have an impact on the price. Some manufacturers may offer additional warranties or maintenance plans, which may be reflected in the price.

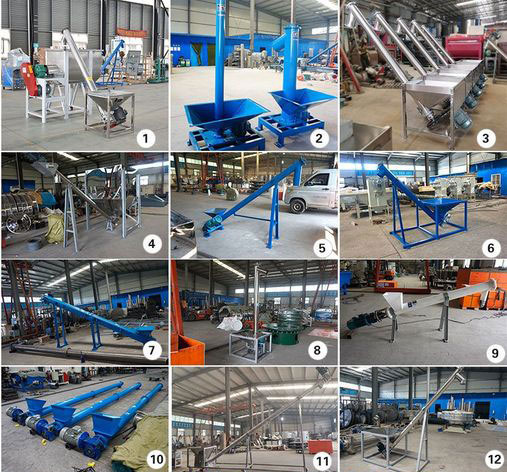

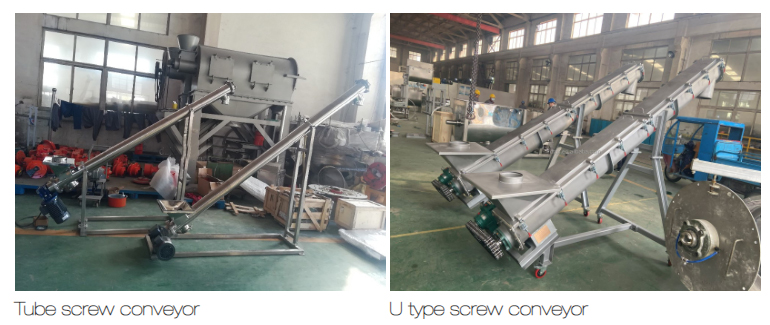

1. Horizontal worm screw conveyor: The screw shaft of this conveyor is installed horizontally and is mainly used to convey materials in the same plane. It is suitable for occasions with relatively long conveying distances and relatively open sites.

2. Inclined worm screw conveyor: The screw shaft is installed at a certain angle to the horizontal plane, and the general inclination angle is within the range of less than 90 degrees. It can convey materials from a lower position to a higher position, or in the opposite direction, and is often used in production links with a certain height difference.

3. Vertical worm screw conveyor: The screw shaft is installed vertically and is used to convey materials vertically upward or downward. It is usually used in occasions where space is limited but the height of the material needs to be raised or lowered.

| Model | Diameter | Pitch(mm) | Speed (r/min) | Delivery volume (m³/h) | Speed (r/min) | Delivery volume (m³/h) | Speed (r/min) | Delivery volume (m³/h) | Speed (r/min) | Delivery volume (m³/h) | Price (USD/unit) | |

| (mm) | ||||||||||||

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 | 400-992 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | ||

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | ||

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | ||

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 | 900-2670 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | ||

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | ||

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 | 2220-5183 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | ||

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | ||

The price of a worm screw conveyor depends on many factors such as size, capacity, material of construction, customization, brand, manufacturer, and delivery/installation costs, etc. It is difficult to provide an accurate price without specific information about the application and requirements.

1. Size and capacity: The larger the screw, the higher the capacity, and the higher the price of the conveyor.

2. Structural materials: Structural materials will affect the price of the conveyor. Conveyors made of high-strength materials like stainless steel tend to be more expensive.

3. Customization: Customizing the screw conveyor to meet specific application requirements will increase the cost.

4. Brand and manufacturer: The brand and manufacturer of the conveyor will also affect the price.

5. Delivery and installation: Transportation and installation costs will also increase the overall cost of the conveyor.

It is important to obtain quotes from multiple manufacturers to compare prices and ensure that the conveyor meets the specific needs of the application. Additionally, ongoing maintenance costs should also be considered when evaluating the overall cost of a worm screw conveyor.

Clear requirements: determine the characteristics of the conveyed material, conveying volume, conveying distance, conveying height and other parameters.

Choose a suitable manufacturer: Choose a qualified and reputable manufacturer to get better product quality and after-sales service.

Compare multiple quotations: Compare quotations from different manufacturers, and comprehensively consider factors such as price, performance and service.

On-site inspection: If conditions permit, it is recommended to inspect the manufacturer's production workshop and installed equipment on site.

1.Don't blindly pursue low prices: Too low prices may result in poor product quality and affect service life.

2.Pay attention to after-sales service: Choose a manufacturer with perfect after-sales service, which can solve problems encountered during use in a timely manner.

3.Consider customized needs: If you have special needs, you can communicate with the manufacturer to customize a conveyor that meets your requirements.

4.The price of worm conveyors is affected by many factors and there is no fixed price. When choosing a worm conveyor, you should consider factors such as price, performance, and quality to choose a product that suits your needs.

To get an accurate quote, please provide the following information:

Type and characteristics of the conveyed material, including particle size and moisture.

Estimated conveying volume (tons per hour).

Horizontal distance and vertical height of conveying.

Whether the material needs to be heated or cooled.

Whether explosion-proof design is required.

Other special requirements or customized needs.

By providing this information, we can recommend a more suitable worm conveyor model for you and provide corresponding quotations.

Warm reminder: The above information is for reference only. Please refer to the manufacturer's quotation for specific prices.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.