High frequency vibrating screen

High frequency vibrating screen Stainless steel high frequency vibrating screen

Stainless steel high frequency vibrating screen Liquid vibrating screen machine with high frequency

Liquid vibrating screen machine with high frequency Ceramic slurry high frequency vibrating screen

Ceramic slurry high frequency vibrating screen Elevated high frequency vibrating screen

Elevated high frequency vibrating screen

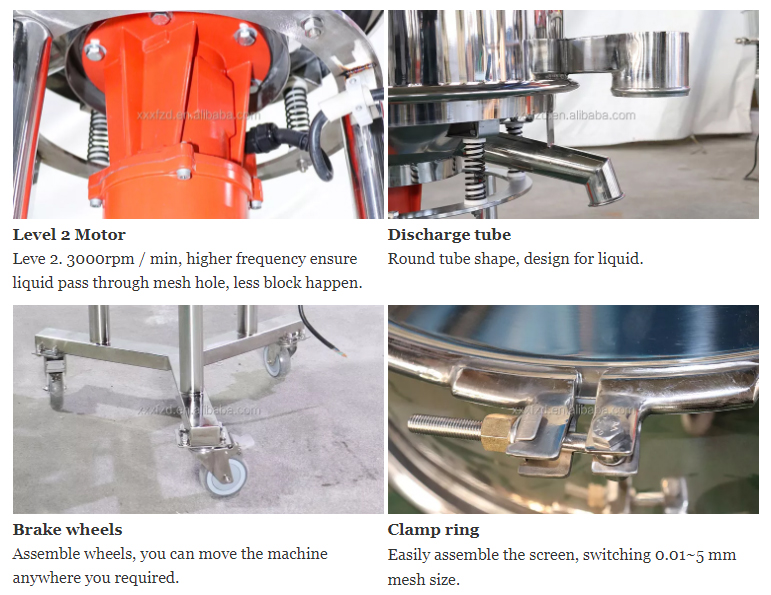

Level 2 Motor, 3000rpm/min higher frequency ensures that liquid passes through the mesh, less blockage occurs.

![]()

![]()

![]()

Price:$1,220.00 - $8,900.00/Set

Consult now and enjoy a 10% discount

Screen diameter: 600mm, 800mm, 1000mm, 1200mm

Mesh size: 0.01~5mm

Vibration Frequency: 3000rpm/min

Power: 0.25-0.4KW (Level 2 Motor)

Capacity: 200-1200 Liter/hour

Voltage: 200-400 v

Dimension(L*W*H): 100*80*110 cm

Weight: 90 Kg

Application: fine-grained, high-viscosity slurries such as ceramics, glazes, coatings, pigments, paints, and slurries

Commitment:

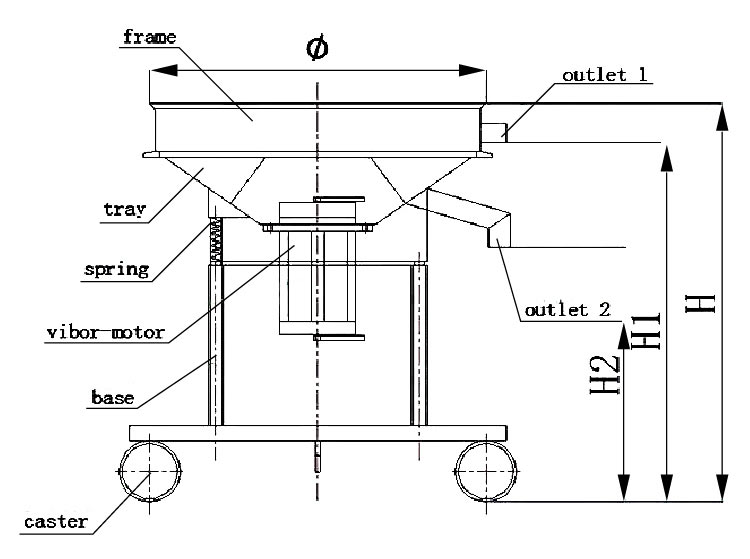

High frequency vibrating screen, also known as high-frequency filter screen, uses a high-frequency vibration motor, a 2-stage high-frequency vibration motor, the vibration frequency is 50 Hz, and the motor speed is 3000 times/min. It breaks its viscosity through high-frequency vibration force The tension of the glaze liquid passes through the screen, and the impermeable impurities are automatically discharged out of the discharge port with the vibration, so as to complete the screening of the material. The vibration intensity of the high frequency vibrating screen is 2-3 times that of ordinary vibrating screens. It is suitable for slurry materials with high viscosity.

The high-frequency vibrating screen is mainly used for the filtration of ceramic glaze, and is one of the mature products developed by our company for the ceramic industry.

Solid-liquid separation: The high-frequency vibrating screen can effectively process solid mixture materials, quickly realize solid-liquid separation, and filter out materials of different meshes.

Impurity removal: It can remove small parts of different sizes in a large amount of liquid materials for rapid separation.

The high frequency vibrating screen uses a high-frequency motor, that is, a 2-stage motor (speed is 3000r/min) as the excitation source to destroy the tension of water molecules in the slurry. The high-frequency vibration makes the slurry smaller than the mesh hole pass through the screen and enter the lower layer The screen frame is discharged from the discharge port. The mud impurities larger than the mesh remain on the screen surface, rotate with the vibrating screen surface, and are screened out from the upper discharge port.

High frequency, low amplitude

The screen surface vibrates at a high frequency, the frequency is 50HZ, the vibration range is 1-2mm, and the vibration intensity is 8-10 times of the acceleration. Compared with the ordinary vibrating screen, the vibration is up to 2-3 times. mesh screen.

High capacity

Impurities and coarse materials are automatically discharged and can be operated automatically. The discharge port of the round tube is specially designed for liquids. glaze.

Not easy to splash and leak

The dish-shaped design is easy to observe the material without splashing, and the heightened design of the upper frame can prevent the slurry from jumping during the filtration process.

long lasting

The screen is made of laminated screen, the single-layer aperture is increased, the service life is prolonged by 2~3 times, and it can also effectively prevent blocking and anti-wear.

Easy to operate

The movable frame can be installed, which can be moved freely in the workplace, the height is adjustable, the installation is not complicated, the operation is simple, and it is not easy to be damaged

Easy to change screen

Using the self-developed "Z" type grid, it is convenient and simple to change the grid. It only takes 3-5 minutes to replace once.

| Difference | High Frequency Vibrating Screen | Ordinary Vibrating Screen | >

| Appearance structure | The single-layer screen box is equipped with two outlets at the same time, one for discharge and one for discharge of slag. The motor is installed at the bottom of the screen box. The bracket can be adjusted to prevent liquid from splashing into the motor and adapt to the screening site environment. | Multi-layer screen boxes can be installed, each layer of screen boxes has a discharge port, the vibration motor is installed in the box, and the machine base is a round table-shaped sealed structure. |

| Motor | 2-stage high-frequency motor, the speed can reach 3000r/min, and the screen box can be used for high-frequency and low-amplitude screen vibration during work, and the surface tension of the material can be quickly destroyed for screening. | Class 4 or class 6 vibrating motor, the speed is only 1000~1500r/min, and the materials are scattered and screened in a circular shape on the screen surface. |

| Applicable materials | It is suitable for screening slurry materials, such as high-concentration ceramic glazes and paints, which can effectively separate slurry and liquid, and is suitable for filtration. | It is more suitable for screening materials without special conditions, such as salt, flour, rice, fruit juice and other granular, powder, and liquid materials. It can only place a single layer of screen for filtering or multiple layers of screen for material class .0 |

Filter slurry

Filter tailings slurry

| Model NO. | Screen Dia. [mm] |

Screen Decks | Vibration Frequency [r/min] |

Power [Kw] |

Capacity [Liter/hour] |

| DHG-600 | 560 | 1 | 3000 | 0.25 | 200 |

| DHG-800 | 760 | 0.25 | 500 | ||

| DHG-1000 | 950 | 0.4 | 800 | ||

| DHG-1200 | 1150 | 0.4 | 1200 |

1. Frequency: The vibration frequency of the high-frequency vibrating screen is about 50HZ. It is precisely because of this high-frequency vibration that the material can be quickly separated, which is suitable for materials with high slurry concentration.

2. Angle: the installation angle of the screen machine is convenient and adjustable, and the installation inclination angle of the wet screening in the concentrator is generally 25±2°

Observation hole: It is convenient to observe the movement of materials, and the observation hole cover is a glass cover and a rubber cover. The glass cover does not need to be removed to watch the material in motion, while the rubber cover is less expensive.

Damping springs: reduce running noise and transmit three-dimensional motion to the frame

Pinball Tray: Makes pinballs clean.

Snap ring: Generally, the machine adopts two kinds of screw fixing and quick opening. You can choose the appropriate one according to your actual requirements.

Discharge port: can control the discharge speed of the material. It is designed as fixed type, pneumatic valve, manual valve 3 types.

Buffer plate: reduce the impact of materials on the screen, so that the screen has a long service life.

Universal Wheel: Can be moved easily.

| General requirements | Diameter Size(mm) | 400/800/1000/1200/1500/2000 |

| Number of Layers(L) | 1 | |

| Main Material | Stainless Steel(304/316L)•Carbon Steel(Q235) | |

| Screen Mesh Number | 5-500 | |

| Sealing Strip | Silica gel / Rubber | |

| Special requirements | Overall height of the fuselage | Please communicate specifically |

| Feed inlet | Angle / Size and so on | |

| Outlet | Angle / Size /Add valve | |

| Observation port | Silicone cover / Rubber cover / Glass cover | |

| spring | You can choose whether to add a silicone protective cover | |

| Internal spray(mm) | PTFE / ePTFE / WC / Al2O3 | |

| Equipment surface treatment | Polishing / Sandblasting | |

| Body metal material requirements | For example: require no Cu and Zn (except electrical parts) | |

| Vibration motor | Ordinary motor / Explosion-proof motor | |

| other | Customized on demand |

High frequency vibrating screen can choose different designs according to industry requirements, such as heightened type, mobile type, closed type, open type, etc.

| Materials | Water content | Mesh size | Screen time | Capacity |

| ceramic mud | 36% | 80mesh | 15-30 days | 8-9t/h |

| Electric porcelain mud | 60% | 200mesh | 30-40 days | 6t/h |

| Electric porcelain mud | 60% | 300mesh | 15-20 days | 1-2t/h |

| Electric porcelain mud | 35% | 180mesh | 15-20 days | 4-7t/h |

| Electric porcelain mud | 35% | 200mesh | 15-20 days | 4t/h |

| Electric porcelain mud | 60% | 160mesh | 15-20 days | 8-10t/h |

| Kaolin slurry | 60% | 200mesh | 20 days | 6-7m³ |

| Kaolin slurry | 60% | 250mesh | 20 days | 5m³ |

| Kaolin | dry powder | 120mesh | 15 days | 2.5t/h |

| Sanitary ware glaze paste | --- | 220mesh/180mesh | 30 days | 400kg/h |

| Ordinary half white glaze | --- | 150mesh | 30 days | 1.4t/h |

| Glaze No. 3 | --- | 140mesh | 30 days | 650kg/h |

High-frequency vibrating screen is specially used for filtration and separation of high-concentration and viscous liquid materials. In order to meet the characteristics and requirements of raw material screening in individual industries, there are various types of designs, such as: edged type, gate type, closed type, open type or mobile wheels, etc.

Our company is committed to solving various screening and filtration problems. The products are widely used in chemical industry, food, medicine, ceramics, casting, construction, mining, abrasives, etc. The products are exported to Germany, Russia, Vietnam, Singapore, Indonesia and other European and American countries and East Asia, Southeast Asia and other parts of the world.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.