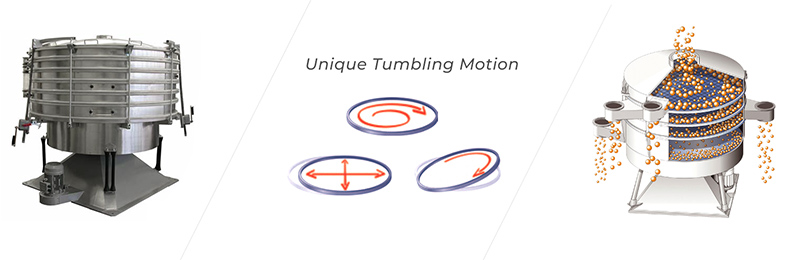

Combining screening (circular motion) and hand sieving (parabolic motion) can be used to separate and remove powdery and granular products.

![]()

![]()

Price:$860.00-$3,680.00/set

Consult now and enjoy a 10% discount

Diameter: 600-2600mm

Feed rate: 1kg/h - 50t/h

Mesh: 20 microns - 20 mm

Number of sieve plates: i>1-5 layers

Anti-blind system: rubber ball/rotating brush/ultrasonic

Amplitude: 40-80 mm horizontally and 5-40 mm vertically

Acceleration: 1,3-1,8 g

Material: carbon steel, stainless steel and special steel

Application:It is used for screening, grading, and dust removal of dry, powdery, and granular products. It is especially suitable for high-throughput, multi-layer sorting of fine, fragile, irregular, and light products that are difficult to screen.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Tunmbler screen, also known as a tumbler sieve or tmbler screening machine, simulates the action of manual screening, that is, combining screening (circular motion) with hand screening (parabolic motion), and can be used for powdery and granular products. Separation and dust removal, the screening accuracy can reach more than 95%.

The Tunmbler screen's acceleration and low-speed operation ensure that the material always rolls on the surface of the screen. The material damage rate is low, the screening accuracy can reach 90%-95%, the output per unit area is up to 5 times, and the material can reach level 6. Classification, especially suitable for precision screening of cylindrical, flaky and other irregular-shaped materials.

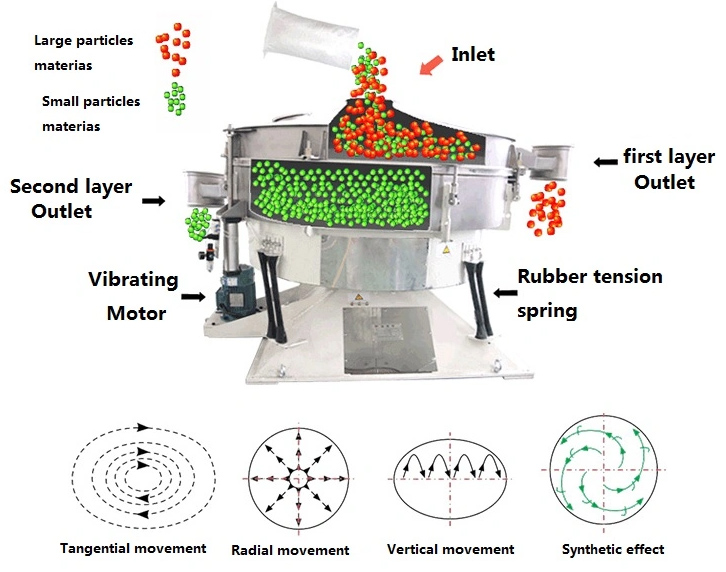

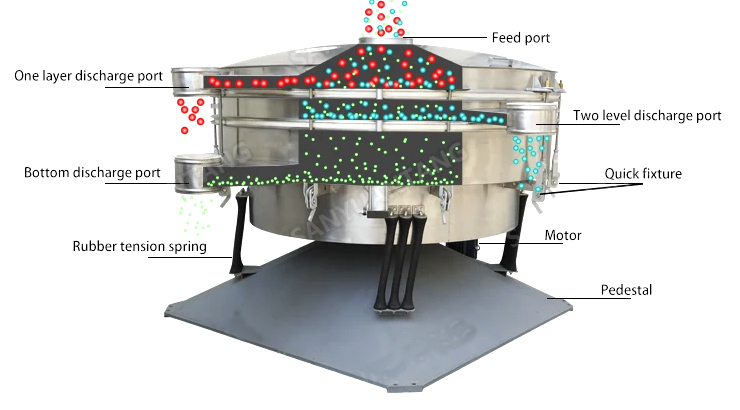

1. Material feeding: Materials enter the screen frame through the feeding port.

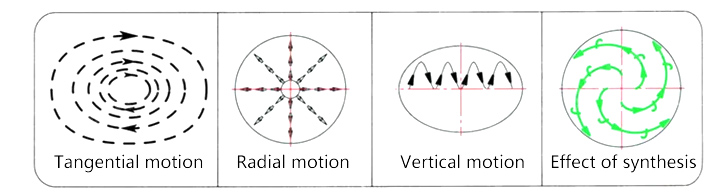

2. Swinging motion: The screen frame begins to swing, that is, swinging left and right with the horizontal axis as the center. This rocking motion causes the material to continuously tumble and slide within the screen frame, thereby promoting the screening process.

3. Vibrating screening: At the same time, the screen mesh in the screen frame vibrates, and the materials are divided into different particle sizes through the aperture of the screen mesh. Materials with larger particles are blocked above the screen, while materials with smaller particles fall through the screen into the outlet below.

4. Discharge: The screened materials are discharged from the discharge port and divided into different particle size levels.

High screening efficiency

The tumbling motion of the screen effectively breaks agglomerates and loose materials, thereby achieving high screening efficiency. It can separate particles of different sizes more accurately.

Handle materials gently

The tumbling action of the screen reduces impact and friction on the material, allowing for gentler handling. This is particularly beneficial for fragile or delicate materials that may be easily damaged or degraded during the screening process.

Multi-tier configuration

Can be designed in multiple layers, allowing materials to be sorted into different sized sections simultaneously. This enhances screening capabilities and efficiency, as well as the flexibility to achieve multiple particle size separations in a single operation.

self cleaning system

Some tunmbler screens are equipped with self-cleaning systems that help prevent clogging and improve overall screening performance. This feature is particularly useful when screening materials with high moisture content or sticky properties.

Noise level around 75 decibels

The moving parts oscillate side to side instead of up and down like a vibrating screen, reducing noise levels while reducing damage to materials.

Easy to maintain and clean

Tunmbler screens often feature quick-release clips or access doors that allow for easy inspection, replacement of screens, and cleaning of the equipment.

| tunmbler screen | ordinary vibrating screen |

| Elliptical rocking (simulated artificial) | High speed vibration screening material |

| No damage to materials | May damage materials |

| Up to 95% accuracy | Accuracy 50%-95% (different materials) |

| No runout, less wear and tear | Knock on the screen surface, the screen mesh is seriously worn |

| Model |

Diameter (mm) |

Screen area (m²) |

Feeding size (mm) |

Screening size (mm) |

Capacity (t/h) |

Amplitude ((mm) |

Power (kW) |

| YBS800 | 800 | 0.29 | ≤25 | 0.073-3 | 6-10 | 5-8 | 0.75 |

| YBS1000 | 1000 | 0.71 | 8-15 | 1.5 | |||

| YBS1200 | 1200 | 1.11 | 15-30 | 2.2 | |||

| YBS1600 | 1600 | 1.83 | 25-40 | 3 | |||

| YBS2000 | 2000 | 2.62 | 30-50 | 4 | |||

| YBS2500 | 2500 | 4.61 | 40-60 | 5.5 |

1. Ultrasonic cleaning: High-frequency ultrasonic waves are transmitted to the screen, which not only cleans the screen but also significantly improves production capacity. It is suitable for most fine, large-volume and difficult-to-screen materials.

2. Bouncing ball cleaning: Food-compliant rubber and silicone balls bounce on the punching plate under the screen and bounce against the metal mesh to reduce mesh clogging. This system is simple to use and maintain, and is suitable for most granular materials.

3. Rotary brush cleaning: The rotary brush is driven by the reduction gear installed on the base chassis. It rotates and brushes under the swing screen mesh to clean the materials. It is suitable for screening spherical, crystallized and brittle materials.

Food industry: Can be used for screening and grading operations in food processing. For example, it can be used to screen flour, sugar powder, starch, cereals, coffee powder and other food raw materials to remove impurities and lumps to ensure product quality and purity.

Chemical industry: used for screening and classifying powder and granular materials. For example, in the production of pigments, plastics, rubber, fertilizers, pesticides, etc., the classification and separation of materials can be achieved through swing screens.

Pharmaceutical industry: Used for screening drug powders, classifying particles and removing impurities to ensure that drugs meet the specified particle size and purity requirements.

Mining industry: It can be used for dry or wet screening of ores to classify and grade the ores according to different particle sizes for subsequent processing and utilization.

Building materials industry: It can be used in the production process of building materials, such as screening and grading of sand, cement, concrete, etc. It can remove impurities and adjust the ratio of different particle sizes to meet the requirements of building materials.

| Materials | Mesh Size | Capacity(kg/h) | Model | |

| tunmbler screen | ordinary vibrating screen | |||

| rubber powder | 24 | 600 | 1000 | φ2000 |

| chili seeds | 4mm | 150 | 500 | φ600 |

| Petroleum coke powder | 110-120 | 1200 | 3000 | φ1800 |

| Panax notoginseng powder | 100 | 200 | 300 | φ600 |

| quartz sand | 2-200 | 6500 | 6500 | φ1800 |

| rice husk | 6mm | 3000 | 4600 | φ2000 |

| medicine powder | 325 | 400 | 600 | φ600 |

| feed | 40 | 1400 | 2200 | φ1800 |

| fertilizer | 2mm | 3300 | 10000 | φ2000 |

Dahan tunmbler screen manufacturer provides tunmbler screen, square tunmbler screen, round tunmbler screen, stainless steel tunmbler screen, ultrasonic tunmbler screen, wood chip tunmbler screen and tunmbler screen extension and other products. They are made of carbon steel and stainless steel, with 1-5 layers. The models are YBS800-YBS2500 are optional and can be designed according to customer requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.